Flame-retardant insulation cable material and preparation method thereof

A technology of insulating cables and flame retardants, applied in insulators, organic insulators, plastic/resin/wax insulators, etc., can solve problems such as a large number of smoke and toxic substances, loss of life and property safety, easy combustion, etc., and achieve good flame retardant effect. , the effect of slowing down the burning rate and increasing the elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

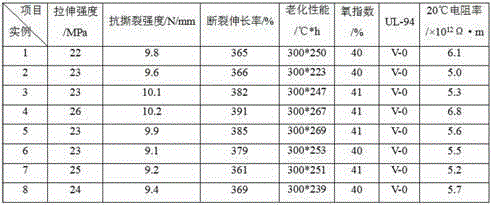

Examples

Embodiment 1

[0023] A flame-retardant insulating cable material is made of the following raw materials in parts by weight:

[0024] 70 parts of high-density polyethylene, 10 parts of ethylene-vinyl acetate copolymer, 10 parts of plasticizer dibutyl phthalate, 3 parts of magnesium hydroxide and red phosphorus (the mass ratio of the two is 5:1), anti- Oxidant 1076 and antioxidant 168 (the mass ratio of the two is 1:1) 0.1 part, titanate coupling agent TMC-TTS 1 part and alumina fiber 6 parts.

[0025] The preparation method of the above-mentioned flame-retardant insulating cable material comprises the following steps:

[0026] (1) Add high-density polyethylene and ethylene-vinyl acetate copolymer into the mixing mixer, then add 60% plasticizer dibutyl phthalate, heat up to 70°C and mix for 3 minutes;

[0027] (2) Add magnesium hydroxide, red phosphorus, antioxidant 1076, antioxidant 168, titanate coupling agent TMC-TTS, alumina fiber and the remaining plasticizer phthalic acid to the mixed ...

Embodiment 2

[0030] A flame-retardant insulating cable material is made of the following raw materials in parts by weight:

[0031] 73 parts of high-density polyethylene, 11 parts of ethylene-vinyl acetate copolymer, 15 parts of plasticizer dioctyl phthalate, 4 parts of magnesium hydroxide and red phosphorus (the mass ratio of the two is 6:1), anti- Oxidant 1076 and antioxidant 168 (the mass ratio of the two is 1:1) 0.2 parts, titanate coupling agent TMC-TTS 1.5 parts and alumina fiber 6 parts.

[0032] The preparation method of the above-mentioned flame-retardant insulating cable material comprises the following steps:

[0033] (1) Add high-density polyethylene and ethylene-vinyl acetate copolymer into the mixing mixer, then add 60% plasticizer dioctyl phthalate, heat up to 80°C and mix for 2 minutes;

[0034] (2) Add magnesium hydroxide, red phosphorus, antioxidant 1076, antioxidant 168, titanate coupling agent TMC-TTS, alumina fiber and the remaining plasticizer phthalic acid to the mi...

Embodiment 3

[0037] A flame-retardant insulating cable material is made of the following raw materials in parts by weight:

[0038] 76 parts of high-density polyethylene, 13 parts of ethylene-vinyl acetate copolymer, 12 parts of plasticizer dibutyl phthalate, 5 parts of magnesium hydroxide and red phosphorus (the mass ratio of the two is 5:1), anti- Oxidant 1076 and antioxidant 168 (the mass ratio of the two is 1:1) 0.27 parts, titanate coupling agent TMC-TTS 2 parts and alumina fiber 7 parts.

[0039] The preparation method of the above-mentioned flame-retardant insulating cable material comprises the following steps:

[0040] (1) Add high-density polyethylene and ethylene-vinyl acetate copolymer into the mixing mixer, then add 65% plasticizer dibutyl phthalate, heat up to 75°C and mix for 5 minutes;

[0041] (2) Add magnesium hydroxide, red phosphorus, antioxidant 1076, antioxidant 168, titanate coupling agent TMC-TTS, alumina fiber and the remaining plasticizer phthalic acid to the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com