Thixotropic bi-compound polyurethane waterproof paint capable of being constructed at high temperature and preparation method thereof

A two-component polyurethane, high-temperature construction technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem that the environmental protection has not been greatly improved, and achieve excellent storage stability, low TDI content, and construction operation long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

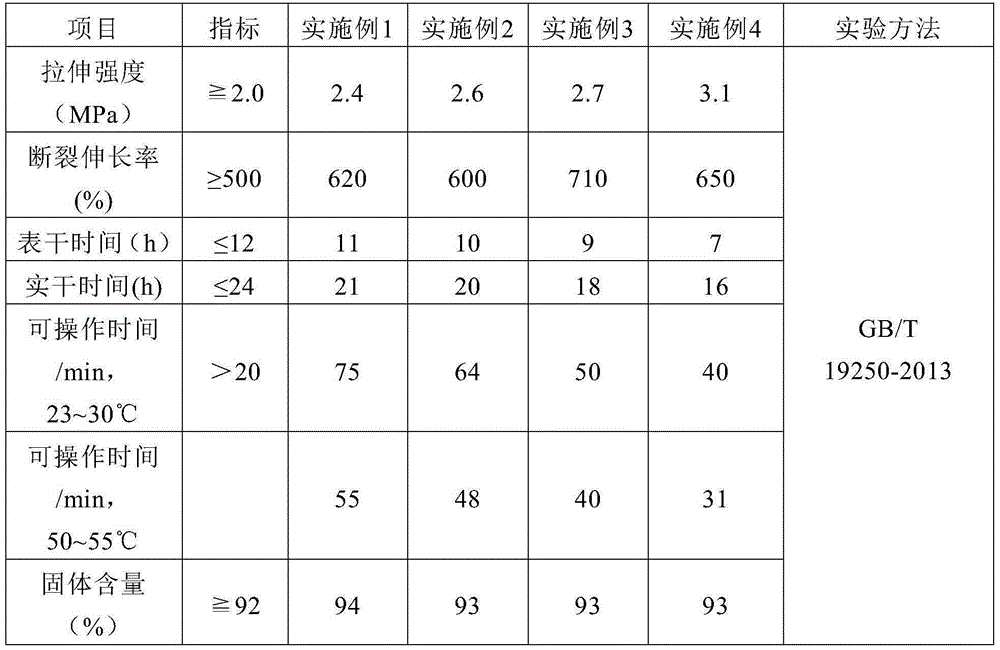

Examples

Embodiment 1

[0035] The preparation method of the thixotropic two-component polyurethane waterproof coating of high temperature construction adopts the following steps:

[0036] Preparation of component A In a 1000mL four-neck flask equipped with a stirrer, condenser, thermometer, and constant pressure dropping funnel, first add 60 parts of polyether diol (2000D) and 15 parts of polyether triol (330N) part and 10 parts of chlorinated paraffin, stirred and heated to 105°C-115°C, vacuum dehydrated for 2-3 hours; cooled the above mixture to 60-70°C, added inhibitor and stirred evenly, then added 5 parts of toluene diisocyanate, 70 After reacting at ℃-80℃ for 1.5 hours, add 20 parts of diphenylmethane diisocyanate, and react at 70℃-80℃ for 1.5 hours; lower the temperature to 50℃-60℃, add 0.1 part of defoamer, and stir for half an hour. Cool down to 40°C-45°C and discharge to obtain component A;

[0037] Add 50 parts of liquid petroleum resin, 30 parts of chlorinated paraffin, 0.5 parts of dis...

Embodiment 2

[0040] The preparation method of the thixotropic two-component polyurethane waterproof coating of high temperature construction adopts the following steps:

[0041] Preparation of component A In a 1000mL four-necked flask equipped with a stirrer, condenser, thermometer, and constant pressure dropping funnel, first add 65 parts of polyether diol (2000D) and 10 parts of polyether triol (330N) part and 10 parts of chlorinated paraffin, stirred and heated to 105°C-115°C, vacuum dehydrated for 2-3 hours; cooled the above mixture to 60-70°C, added inhibitor and stirred evenly, then added 5 parts of toluene diisocyanate, 70 After reacting at ℃-80℃ for 1.5 hours, add 25 parts of diphenylmethane diisocyanate and react at 70℃-80℃ for 1.5 hours; lower the temperature to 50℃-60℃, add 0.1 part of defoamer, and stir for half an hour. Cool down to 40°C-45°C and discharge to obtain component A;

[0042] Add 50 parts of liquid petroleum resin, 30 parts of chlorinated paraffin, 0.5 parts of di...

Embodiment 3

[0045] The preparation method of the thixotropic two-component polyurethane waterproof coating of high temperature construction adopts the following steps:

[0046] Preparation of component A In a 1000mL four-neck flask equipped with a stirrer, condenser, thermometer, and constant pressure dropping funnel, first add 60 parts of polyether diol (2000D) and 15 parts of polyether triol (330N) part and 10 parts of chlorinated paraffin, stirred and heated to 105°C-115°C, vacuum dehydrated for 2-3 hours; cooled the above mixture to 60-70°C, added inhibitor and stirred evenly, then added 5 parts of toluene diisocyanate, 70 After reacting at ℃-80℃ for 1.5 hours, add 30 parts of diphenylmethane diisocyanate and react at 70℃-80℃ for 1.5 hours; lower the temperature to 50℃-60℃, add 0.5 parts of defoamer, and stir for half an hour. Cool down to 40°C-45°C and discharge to obtain component A;

[0047] Add 50 parts of liquid petroleum resin, 30 parts of chlorinated paraffin, 0.5 parts of dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com