A kind of yag:mn red phosphor and its preparation method and application

A red phosphor, red light technology, applied in the field of YAG:Mn red phosphor and its preparation, can solve the problems of high cost, low chemical stability, affecting the overall performance of white light LED devices, etc., and achieves low cost and simple preparation process. , the effect of good thermal and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0038] Analytical pure Y 2 o 3 、Al 2 o 3 , MgCO 3 、H 3 BO 3 , MnO press Y 3 al 4.5 o 12 :0.1Mn 4+ / 0.4Mg 2+ Add 2wt% H after accurate weighing 3 BO 3 Put it in an agate mortar, mix and grind evenly in the agate mortar, put it in a corundum crucible, put it in a high-temperature furnace, heat it to 1500°C, and keep it warm for 4 hours to sinter it into a block. Grind the obtained bulk phosphor evenly in an agate mortar to form a micron-sized powder.

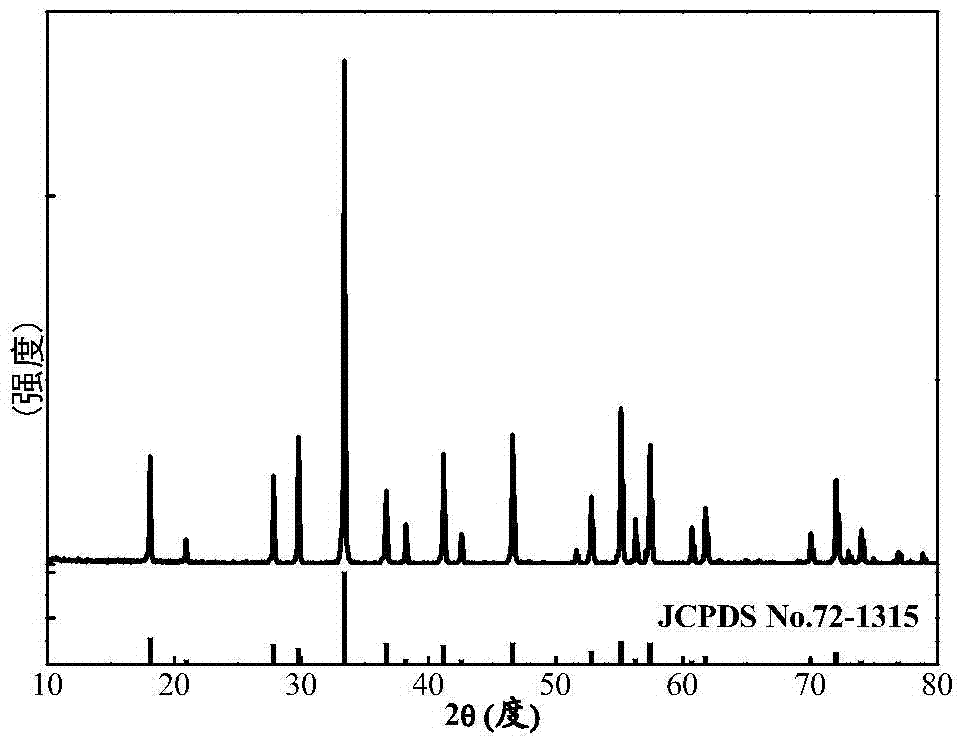

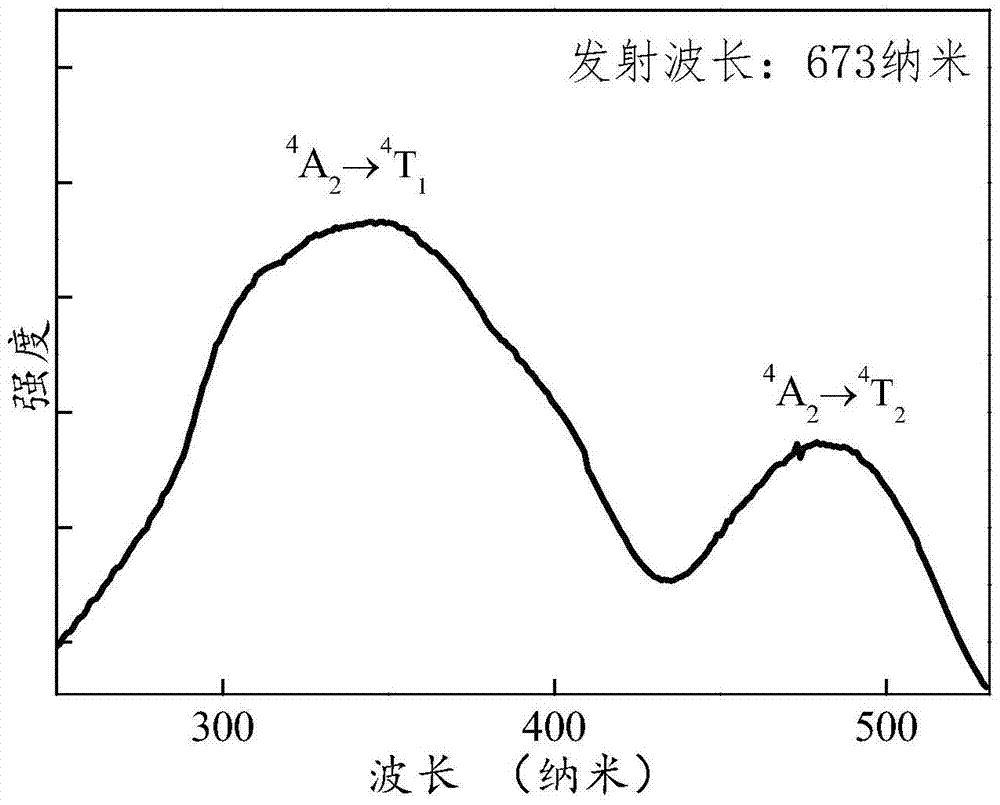

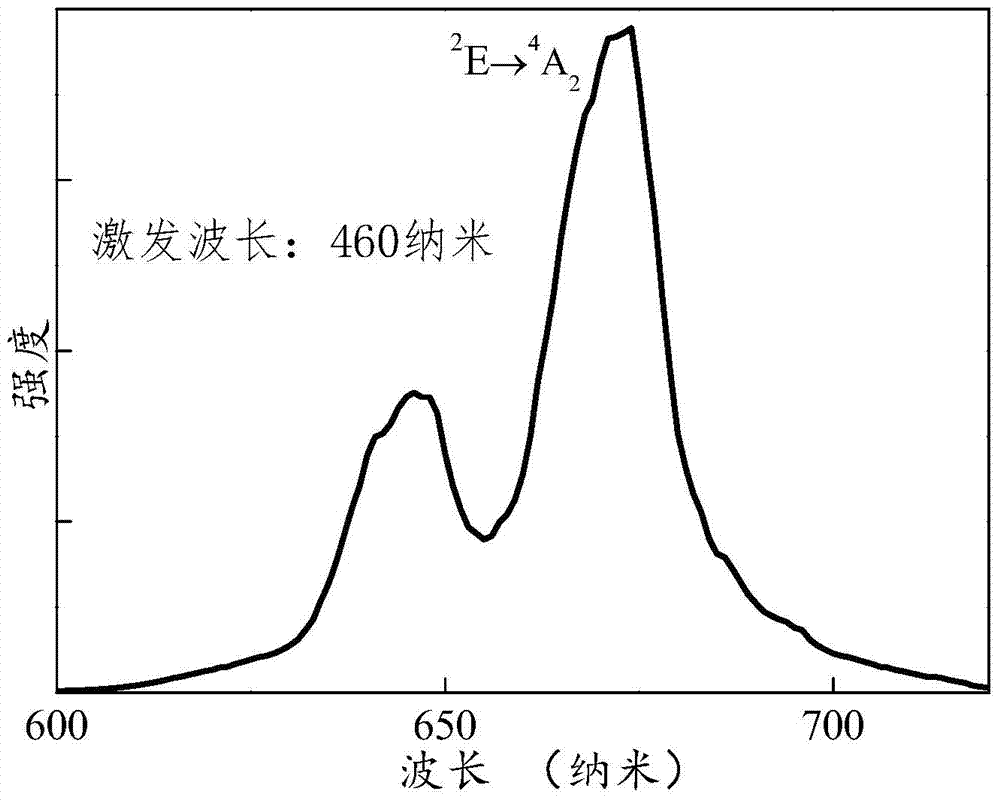

[0039] XRD data shows that the prepared YAG of the present invention: Mn fluorescent powder is cubic structure pure phase (such as figure 1 shown), the addition of co-doped ions has no effect on the structure of YAG. Excitation and emission spectra at room temperature were measured with FS5 fluorescence spectrometer. monitoring Mn 4+ On the excitation spectrum of ion 673 nm emission, the detection corresponds to the Mn 4+ : 4 A 2 → 4 T 1 , 4 T 2 Excitation bands in the transitional ultraviolet (250-430 nm) a...

Embodiment 3

[0041] Analytical pure Y 2 o 3 、Al 2 o 3 , MgCO 3 、H 3 BO 3 , MnO press Y 3 al 4.1 o 12 :0.1Mn 4+ / 0.8Mg 2+ Add 2wt% H after accurate weighing 3 BO 3 Place in different agate mortars, mix and grind evenly in the agate mortar, put them in different corundum crucibles, put them in a high-temperature furnace, heat them to 1500°C and keep them warm for 4 hours to sinter them into blocks. Grind the obtained bulk phosphor evenly in an agate mortar to form a micron-sized powder. Measure the emission spectrum at room temperature with FS5 fluorescence spectrometer and find that 0.8Mg 2+ The co-doped YAG:Mn phosphor has 11 times higher luminous intensity than the YAG:Mn without doping other ions.

Embodiment 4

[0043] Analytical pure Y 2 o 3 、Al 2 o 3 , CaCO 3 、H 3 BO 3 , MnO press Y 2.6 al 4.9 o 12 :0.1Mn 4+ / 0.4Ca 2+ Add 4wt% H after accurate weighing 3 BO 3 Put it in different agate mortars, mix and grind evenly in the agate mortar, put it in different corundum crucibles, put it in a high-temperature furnace, heat it to 1400°C, and keep it warm for 5 hours to sinter it into a block. Grind the obtained bulk phosphor evenly in an agate mortar to form a micron-sized powder. Measure the emission spectrum of the sample at room temperature with a FS5 fluorescence spectrometer, and find that 0.4Ca 2+ The co-doped YAG: Mn phosphor has 9 times higher luminous intensity than the YAG: Mn without doping other ions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com