A method of electrolyzing organic matter to construct a diamond-like film on a metal surface

A diamond thin film and metal surface technology, applied in the chemical field, can solve the problems of high cost, difficult and complex surface film formation, complicated process, etc., and achieve the effects of low cost, good film-base bonding force and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

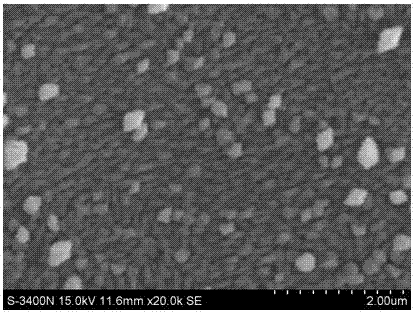

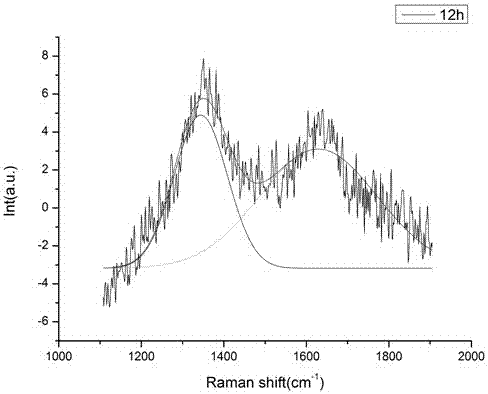

Image

Examples

Embodiment 1

[0025] A method for electrolyzing organic matter to construct a diamond-like carbon film on a copper surface, comprising the steps of:

[0026] (1) Copper foil surface pretreatment: ultrasonically clean the copper foil with acetone and ethanol for 30 minutes at room temperature, and then wash it with deionized water. Polish the copper foil by immersing it in the polishing solution, and then rinse it with deionized water.

[0027] The copper foil is copper (purity greater than 99.95%);

[0028] The polishing solution is an aqueous solution of phosphoric acid. Wherein, the volume ratio of phosphoric acid and deionized water is 0.6.

[0029] (2) Electrolyte preparation: The electrolyte is composed of n-methylpyrrolidone (NMP) and deionized water. Dissolve NMP in deionized water, prepare a certain concentration of NMP aqueous solution, and ultrasonically disperse within a certain temperature range for 30 minutes.

[0030] In the electrolyte, the volume ratio of NMP and deioniz...

Embodiment 2

[0040] A method for electrolyzing organic matter to construct a diamond-like carbon film on a copper surface, comprising the steps of:

[0041] (1) Copper foil surface pretreatment: ultrasonically clean the copper foil with acetone and ethanol for 30 minutes at room temperature, and then wash it with deionized water. Polish the copper foil by immersing it in the polishing solution, and then rinse it with deionized water.

[0042] The copper foil is brass;

[0043] The polishing liquid is an aqueous solution of phosphoric acid, wherein the volume ratio of phosphoric acid and deionized water is 0.6.

[0044] (2) Electrolyte preparation: The electrolyte is composed of n-methylpyrrolidone (NMP) and deionized water. Dissolve NMP in deionized water, prepare a certain concentration of NMP aqueous solution, and ultrasonically disperse within a certain temperature range for 30 minutes.

[0045] In the electrolyte, the volume ratio of NMP and deionized water is 0.2;

[0046] The tem...

Embodiment 3

[0054] A method for electrolyzing organic matter to construct a diamond-like carbon film on a copper surface, comprising the steps of:

[0055] (1) Copper foil surface pretreatment: ultrasonically clean the copper foil with acetone and ethanol for 30 minutes at room temperature, and then wash it with deionized water. Polish the copper foil by immersing it in the polishing solution, and then rinse it with deionized water.

[0056] The copper foil is copper;

[0057] The polishing solution is an aqueous solution of phosphoric acid. Wherein, the volume ratio of NMP and deionized water is 0.6.

[0058] (2) Electrolyte preparation: The electrolyte is composed of n-methylpyrrolidone (NMP) and deionized water. Dissolve NMP in deionized water, prepare a certain concentration of NMP aqueous solution, and ultrasonically disperse within a certain temperature range for 30 minutes.

[0059] In the described electrolyte, the volume ratio of NMP and deionized water is 0.1;

[0060] The te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com