High-intensity ternary gradient structure PVDF tubular ultrafilter membrane and preparation method

A technology of tubular ultrafiltration membrane and gradient structure, which is applied in the field of high-strength ternary gradient structure PVDF tubular ultrafiltration membrane and its preparation, and can solve the problem of loose bonding between the support layer and the separation layer, uneven porosity, and low bonding strength and other problems, to achieve the effect of good application prospects, large flux and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

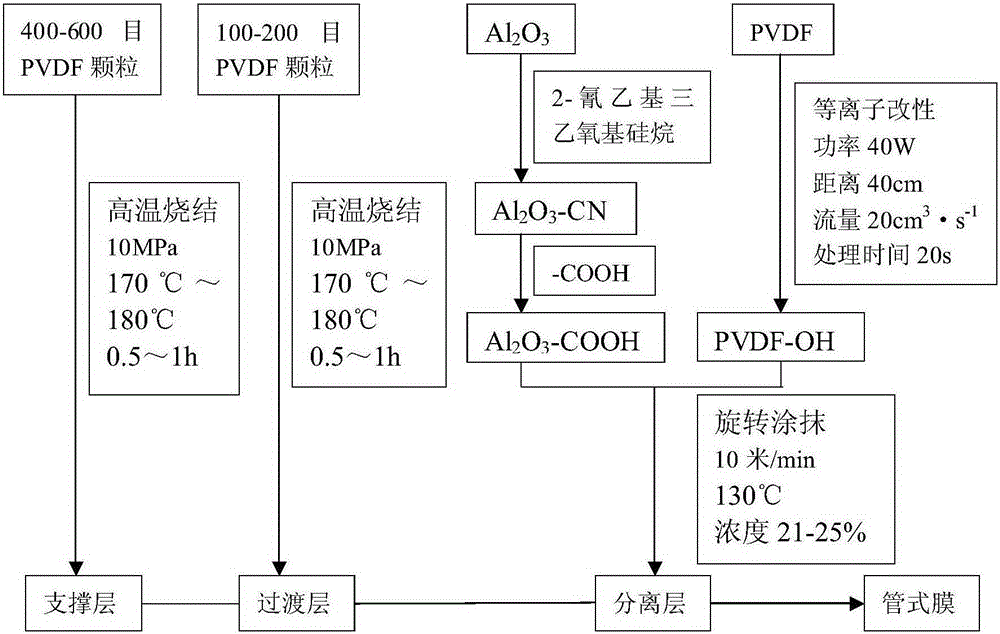

Method used

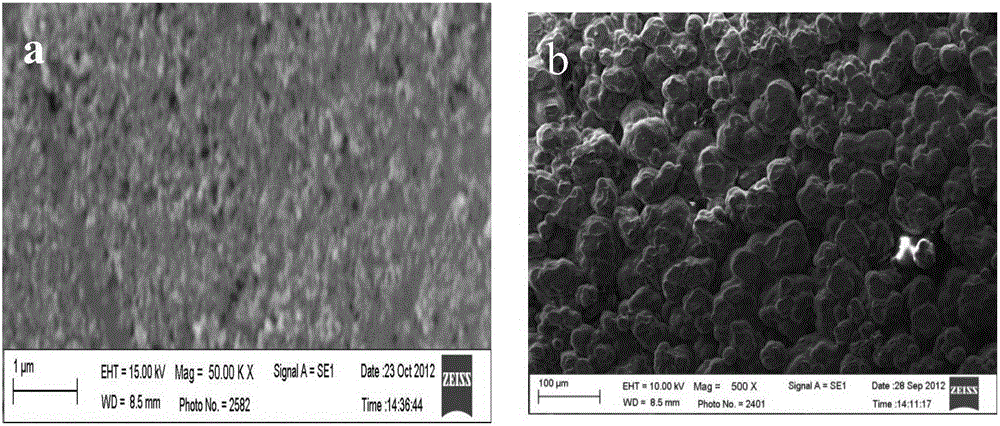

Image

Examples

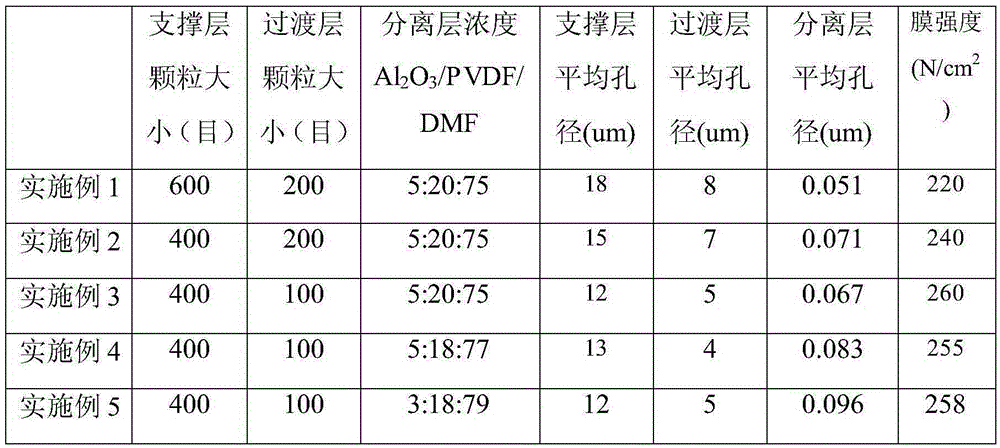

Embodiment 1

[0035] (1) Pour the PVDF powder with a particle size of 200 meshes into a stainless steel tubular mold with an inner tube and an outer tube, and control the thickness of the support layer to be 2mm by adjusting the gap between the inner diameter of the outer tube and the outer diameter of the inner tube. Under 10MPa pressure conditions and High-temperature sintering at 180°C for 1 hour, cooling to room temperature at a rate of 10°C / min, and exiting the mold to form a support layer tubular prefabricated body with a one-layer structure.

[0036](2) Pour the PVDF powder with a particle size of 600 meshes into the transition layer sintering mold. The transition layer sintering mold is based on the inner layer of the support layer tubular prefabricated body as the outer layer of the transition layer, and uses a stainless steel tube with an outer diameter smaller than the tubular prefabricated body As the inner tube mold for transition layer sintering, adjust the difference between t...

Embodiment 2

[0040] (1) Pour the PVDF powder with a particle size of 200 meshes into a stainless steel tubular mold with an inner tube and an outer tube, and control the thickness of the support layer to be 2mm by adjusting the gap between the inner diameter of the outer tube and the outer diameter of the inner tube. Under 10MPa pressure conditions and High-temperature sintering at 180°C for 1 hour, cooling to room temperature at a rate of 10°C / min, and exiting the mold to form a support layer tubular prefabricated body with a one-layer structure.

[0041] (2) Pour the PVDF powder into the transition layer sintering mold with a particle size of 400 meshes. The transition layer sintering mold is based on the inner layer of the support layer tubular prefabricated body as the outer layer of the transition layer, and the outer diameter is less than the stainless steel tube of the tubular prefabricated body As the inner tube mold for transition layer sintering, adjust the difference between the ...

Embodiment 3

[0045] (1) Pour the PVDF powder with a particle size of 100 mesh into a stainless steel tubular mold with an inner tube and an outer tube, and control the thickness of the support layer to be 2mm by adjusting the gap between the inner diameter of the outer tube and the outer diameter of the inner tube. Under 10MPa pressure conditions and High-temperature sintering at 180°C for 1 hour, cooling to room temperature at a rate of 10°C / min, and exiting the mold to form a support layer tubular prefabricated body with a one-layer structure.

[0046] (2) Pour the PVDF powder into the transition layer sintering mold with a particle size of 400 meshes. The transition layer sintering mold is based on the inner layer of the support layer tubular prefabricated body as the outer layer of the transition layer, and the outer diameter is less than the stainless steel tube of the tubular prefabricated body As the inner tube mold for transition layer sintering, adjust the difference between the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com