Porous hollow tubular composite membrane and preparation method and application thereof

A composite membrane, tubular technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of rising fluid resistance and falling flow rate of fixed bed, and achieve large adsorption capacity and compact structure. , the effect of fast adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Porous Hollow Tubular Composite Membrane Device for Removing Fluoride from Tap Water

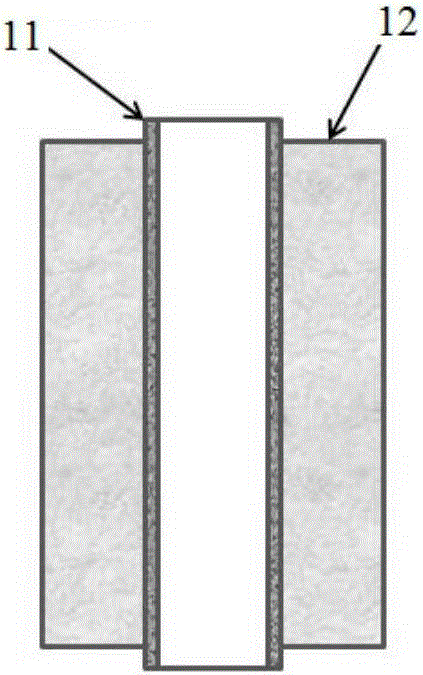

[0054] Preparation of porous hollow tubular composite membrane 1: dissolving chitosan in 1 wt% acetic acid aqueous solution to prepare 2L of chitosan solution with a concentration of 0.5%. Add 400g of adsorbent particle powder to it and configure it into a suspension; the adsorbent particle is mixed with 4A molecular sieve, calcium phosphate, γ-alumina particles, and quick-release powder in a mass ratio of 1:1:0.8:0.2. The particle size of each adsorbent particle is 40 microns-50 microns. A porous hollow alumina ceramic tube is selected as the porous hollow tubular carrier 11, the outer diameter of the ceramic tube is 10 mm, the wall thickness is 1 mm, and the length is 150 mm. Block one end of the porous hollow tubular carrier 11, and connect the other end to a vacuum filtration device, immerse the entire porous hollow tubular carrier 11 in the suspension, and filter with suction to...

Embodiment 2

[0081] Hollow Porous Composite Membrane Device for Removing Fluorine from Concentrated Water Discharged from Reverse Osmosis Process

[0082] Preparation of the porous hollow tubular composite membrane 1: dissolving chitosan in 1 wt% acetic acid aqueous solution to prepare 2L of 1% chitosan solution. Add 400g of adsorbent particle powder into it and configure it into a suspension; the adsorbent particles are composed of 4A molecular sieve, calcium phosphate, γ-alumina particles, and hollow nano-alumina fibers (outer diameter is about 500nm, inner diameter is 300nm, and length is 20 microns) , Pseudoboehmite is mixed according to the mass ratio of 1:1:0.4:0.4:0.2, except for the hollow nano-alumina fiber, the particle size of the other four adsorbents is 40 microns-50 microns. The porous hollow alumina fiber is selected as the porous hollow tubular carrier 11, the outer diameter of the alumina fiber is 5 mm, the wall thickness is 1 mm, and the length is 100 mm. With reference ...

Embodiment 3

[0098] Hollow Porous Composite Membrane Device for Removing Fluoride from Groundwater

[0099] Preparation of Porous Hollow Tubular Composite Membrane 1: Refer to Example 2 for the preparation process of Porous Hollow Tubular Composite Membrane 1.

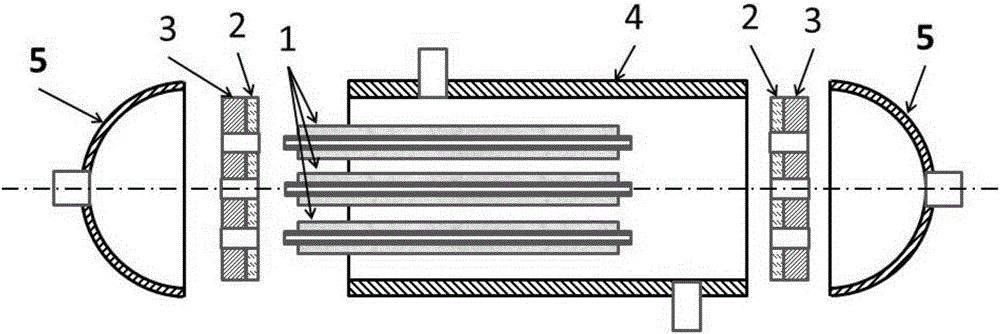

[0100] Assembly of the shell-and-tube adsorption device: the above-mentioned seven porous hollow tubular composite membranes 1, cylinder 4 with an inner diameter of 80mm, sealing gasket 2, support frame 3, head 5, etc. are composed of a shell-and-tube adsorption device. Two shell-and-tube adsorption devices are used in parallel, that is, the water inlet and outlet of one shell-and-tube adsorption device are respectively connected with the water inlet and water outlet of the other shell-and-tube adsorption device. In order to increase the processing capacity of the whole system.

[0101] Defluorination of groundwater: The concentration of fluoride ions in the ground was measured to be 3.8mg / L. The groundwater passed through the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com