A kind of plate-type hydrophobic polymer double-effect MVR system and wastewater concentration method

A hydrophobic polymer, plate evaporator technology, applied in the field of water treatment, can solve the problems of high heat loss, poor anti-scaling and anti-corrosion performance of the heat exchange surface, unable to achieve zero discharge of sewage, etc., to reduce the loss of heat transfer temperature difference , the effect of enhancing the heat transfer effect of condensation and reducing the risk of scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

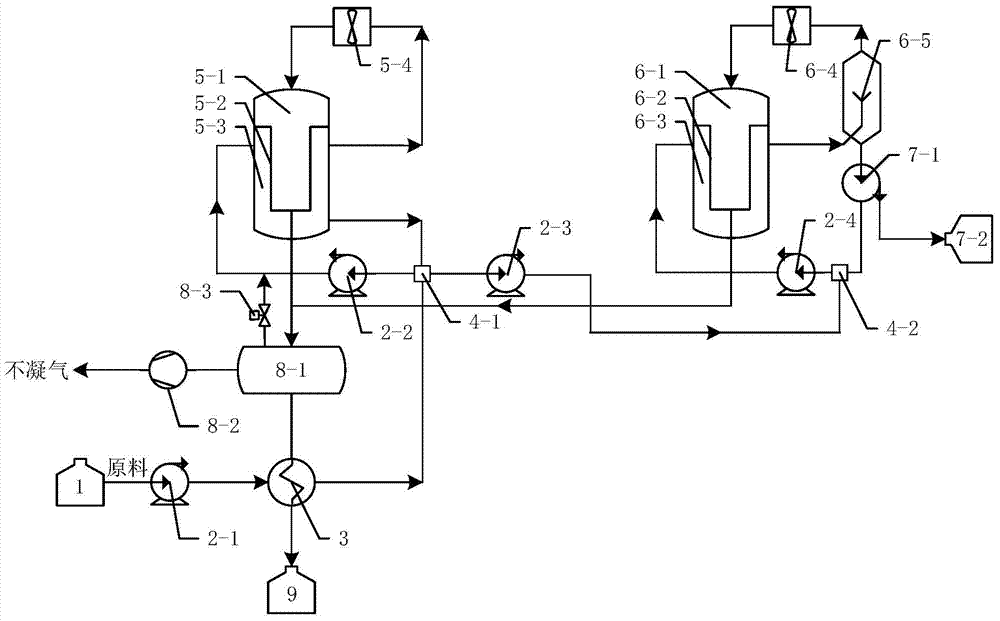

[0055] Embodiment 1, plate polymer double-effect MVR system

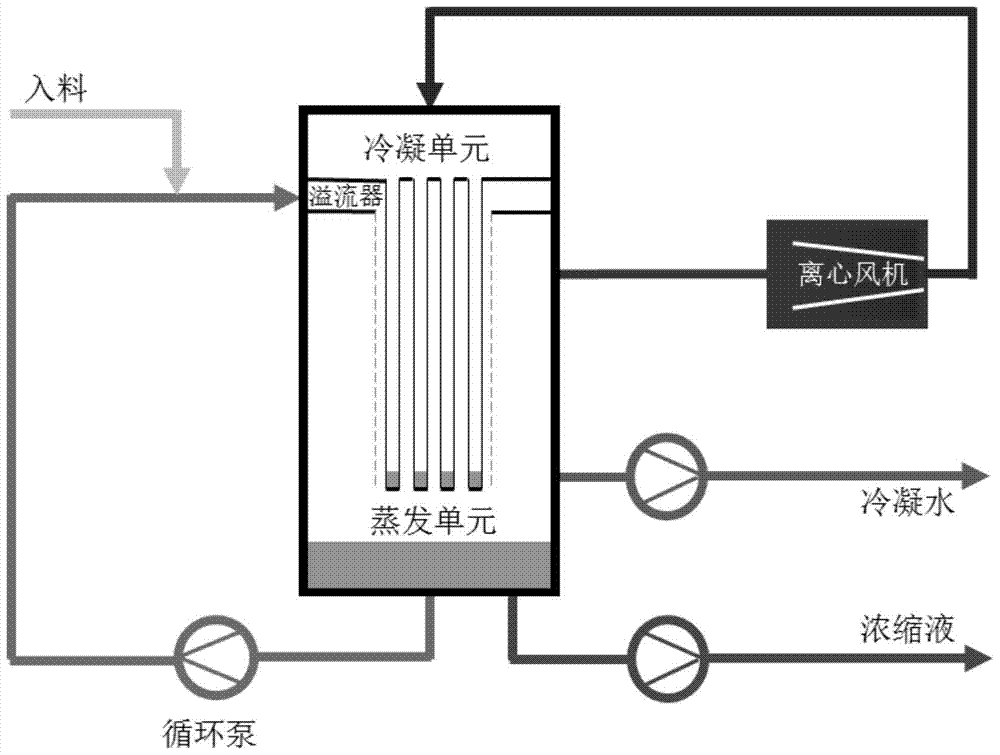

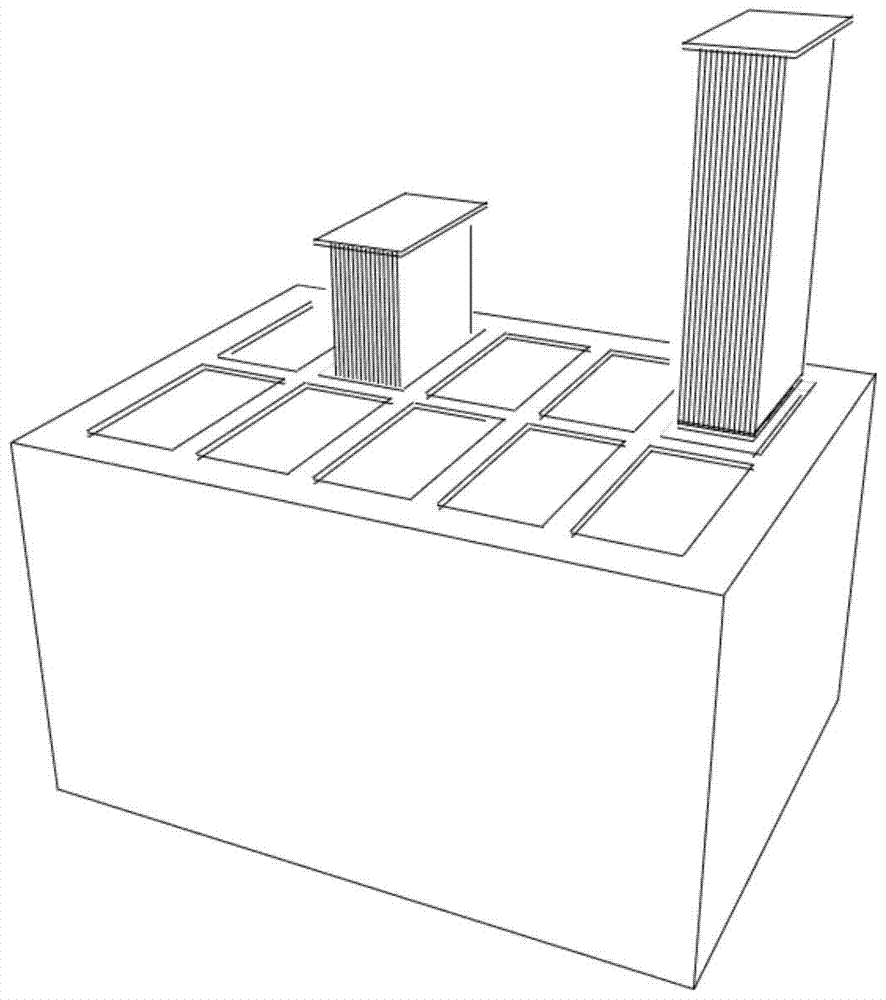

[0056] Such as figure 1 As shown, the double-effect MVR system of the present invention comprises a raw material storage tank (1), a booster, a preheater (3), an adjustable one-effect flow mixer (three-way flow control valve) (4-1) , a first-effect MVR device, a second-effect mixer (4-2), a second-effect MVR device, a concentrated liquid recovery tank (7-2) and a condensate recovery device; the booster device includes a raw material pump (2-1), a first-effect Circulation pump (2-2), inter-effect booster pump (2-3) and second-effect circulation pump (2-4); feed inlet, discharge outlet, condensed water inlet and condensed water outlet are provided on the preheater The one-effect MVR device includes a one-effect MVR evaporator and a centrifugal fan (5-4); the one-effect MVR evaporator is a reactor, which is separated into a one-effect evaporation unit (5-3) by a plug-in detachable plate evaporator And a one-effect co...

Embodiment 2

[0064] Embodiment 2, the control of total dissolved solid content of feed liquid

[0065] When the double-effect MVR system in Example 1 is used to concentrate the feed liquid, the BPE value of the feed liquid, that is, the boiling point elevation value, is in the range of 0-2.1°C. According to the law of solution boiling point rise (the inference of Raoult's law, the calculation formula

[0066]

[0067] Among them, ΔT is the boiling point liter, K; R is the gas constant, for water vapor, R is 0.462kJ / (kg K); T 0 is the boiling point temperature of pure solvent, K; γ 0 For pure solvent at T 0 molar latent heat of vaporization, kJ / kg; is the mole fraction increment of the solute in the dilute solution.

[0068] Since the calculation here is the boiling point liter relative to the pure solution, it can be regarded as adding a solute to a pure solvent with a concentration of 0, that is, the mole fraction increase of the solute and the mole fraction of solute (x 2 ) ar...

Embodiment 3

[0073] Example 3, the relationship between the power of the one-effect circulation pump and the temperature rise of the solution in the one-effect evaporation unit

[0074] Take the NaCl solution with a solute mass fraction of 5% as an example, as Figure 6 As shown, the power consumption of the one-effect circulating pump (2-2) decreases as the temperature rise of the solution in the one-effect evaporation unit (5-3) increases, because the higher the temperature rise, the less the amount of circulating solution required; At the same time, when the temperature rises 1.5-2.5°C, the pump power drops more obviously, so the more suitable temperature rise range should be 2.5-5.5°C; image 3 It can also be seen that the evaporation temperature of the solution in the first-effect evaporation unit (5-3) (the evaporation temperatures of the three curves in the figure are 50°C, 60°C and 70°C respectively) has no obvious influence on the pump power.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com