Integrated treatment method of p-(beta-sulfatoethylsulfonyl)aniline production wastewater

A technology for the production of sulfuric acid ethyl sulfone and waste water, which is applied in biological water/sewage treatment, water/sewage treatment, natural water treatment, etc. It can solve the problems of complete removal of pollutants, high COD concentration, and complex waste water composition. Achieve the effect of strong anti-toxicity and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

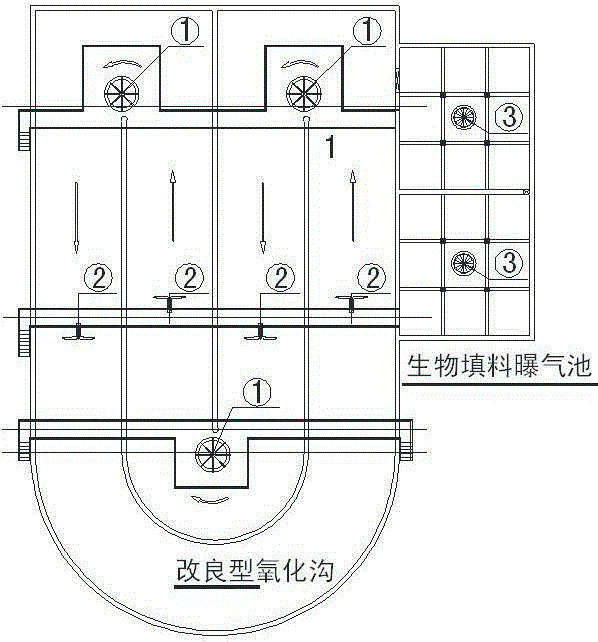

Method used

Image

Examples

Embodiment 1

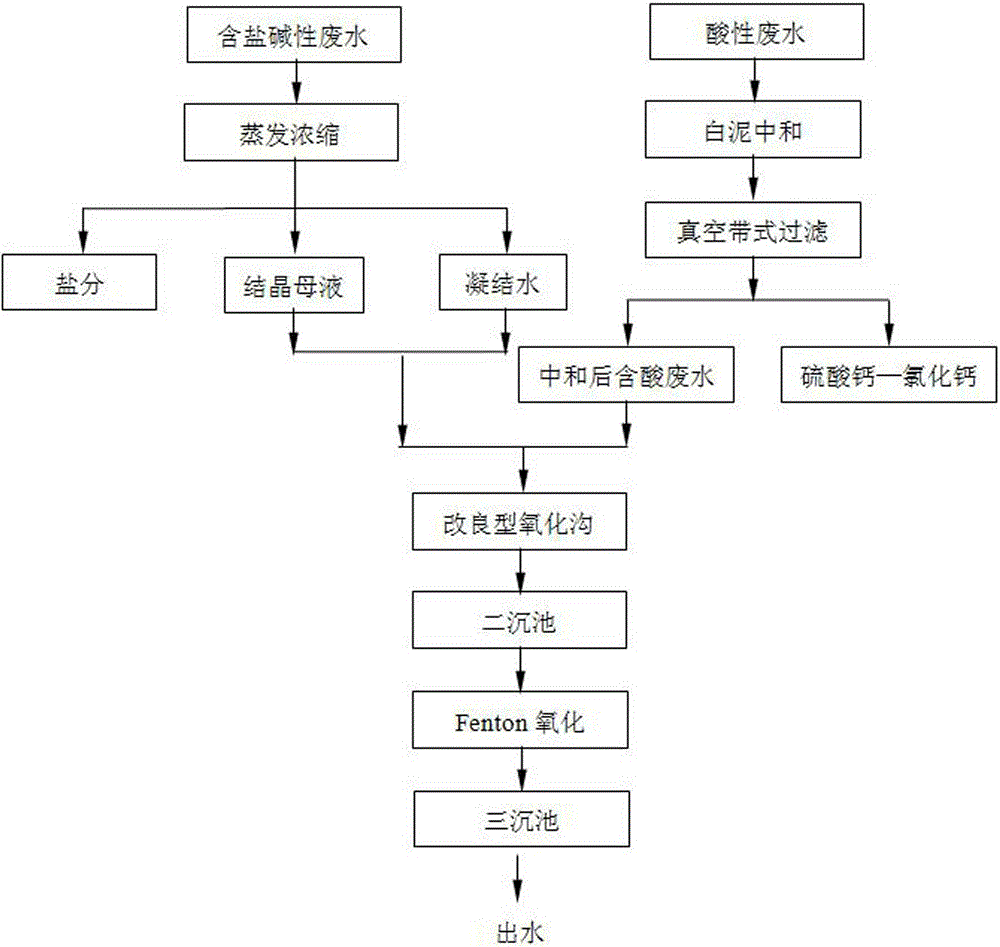

[0025] The main product of an enterprise is p-(β-sulfate ethyl sulfone) aniline. The production process of the enterprise is the acetanilide method, that is, acetanilide undergoes chlorosulfonation, reduction, and then condenses with ethylene oxide for esterification. The raw materials used in production include chlorosulfonic acid, acetanilide, ethylene oxide, liquid caustic soda, sulfuric acid, sodium metabisulfite, etc. The production wastewater of enterprises mainly includes saline alkaline wastewater and acid wastewater containing inorganic acids. The wastewater has complex components and high concentration of organic matter, which is extremely difficult to degrade high-concentration organic wastewater. The wastewater volume and quality data are as follows:

[0026] Acidic wastewater generated in the chlorosulfonation production section: water volume Q=1000m 3 / d

[0027] COD cr =5500mg / L contains 2.8% acid.

[0028] Salt-containing alkaline wastewater generated in re...

Embodiment 2

[0039] The biochemical effluent (CODcr610mg / L) of Example 1 was treated by the improved oxidation ditch, and then entered the Fenton oxidation fluidized tower for Fenton oxidation treatment, and the Fenton fluidized tower was filled with 10% modified basalt filler. The modification process of basalt filler is as follows: crush massive basalt to 0.5-2mm, mix with 10% ferrous sulfate solution, neutralize to pH 6 with 30% NaOH solution, remove excess liquid, and soak the impregnated basalt The filler is sintered in an industrial kiln at 600°C for 2 hours and then cooled to complete the modification of the basalt filler. The operating conditions of Fenton oxidation are: pH is 3.0, [H 2 o 2 ] dosage is 40mmol / L, FeSO 4 ·7H 2 O dosage 10mmol / L, [H 2 o 2 ] / [Fe 2+ ] The molar ratio is 4:1, and the reaction time is 2 hours. After the reaction, the pH is adjusted to 7-8 with 30% NaOH, and the effluent enters the triple sedimentation tank for mud-water separation. After Fenton oxid...

Embodiment 3

[0041] The biochemical effluent (CODcr610mg / L) of Example 1 was treated by the improved oxidation ditch, and then entered into the Fenton oxidation fluidized tower for Fenton oxidation treatment, and the Fenton fluidized tower was filled with 15% modified basalt filler. Modification of basalt filler: crush massive basalt to 0.5-2mm, mix with 15% ferrous sulfate solution, neutralize to pH 7 with 30% NaOH solution, remove excess liquid, mix impregnated basalt filler with After sintering in an industrial kiln at 650°C for 2.5 hours and then cooling, the modification of the basalt filler is completed. The operating conditions of Fenton oxidation are: pH is 3.3, [H 2 o 2 ] dosage is 30mmol / L, FeSO 4 ·7H 2 O dosage 10mmol / L, [H 2 o 2 ] / [Fe 2+ ] The molar ratio is 3:1, and the reaction time is 2.5 hours. After the reaction, the pH is adjusted to 7-8 with 30% NaOH, and the effluent enters the triple sedimentation tank for mud-water separation. After Fenton oxidation, the effluen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com