Novel organic and inorganic hybrid silicon resin nano particles and preparation method

A technology of nanoparticles and hybrid silicon, which is applied in the field of preparation of organic-inorganic hybrid silicone resin nanoparticles by precipitation method, can solve the problems of increasing cost, reducing the modification effect of silica, and affecting properties such as silica particle size, etc. Achieve the effect of improving the degree of dispersion, low equipment requirements, and strengthening strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing organic-inorganic hybrid silicone resin nanoparticles according to claim 1, characterized in that it comprises the steps of:

[0025] 1) Mix 50-100 parts by weight of water and 10-50 parts by weight of alcohol to prepare an aqueous alcohol solution, add it to the reactor, feed in nitrogen and stir to remove HCl generated by the reaction, and control the reaction temperature at 20-40 degrees Celsius;

[0026] 2) Add 10-30 parts by weight of bis(trichlorosilyl)ethane dropwise into the reactor for reaction within 10-60 minutes, add 10-50 parts by weight of alcohol after the dropwise addition and continue the reaction for 10-30 minutes , the obtained precipitate was filtered, washed with water, and dried to obtain organic-inorganic hybrid silicone resin nanoparticles.

[0027] The alcohol is an organic alcohol with 2 to 6 carbon atoms.

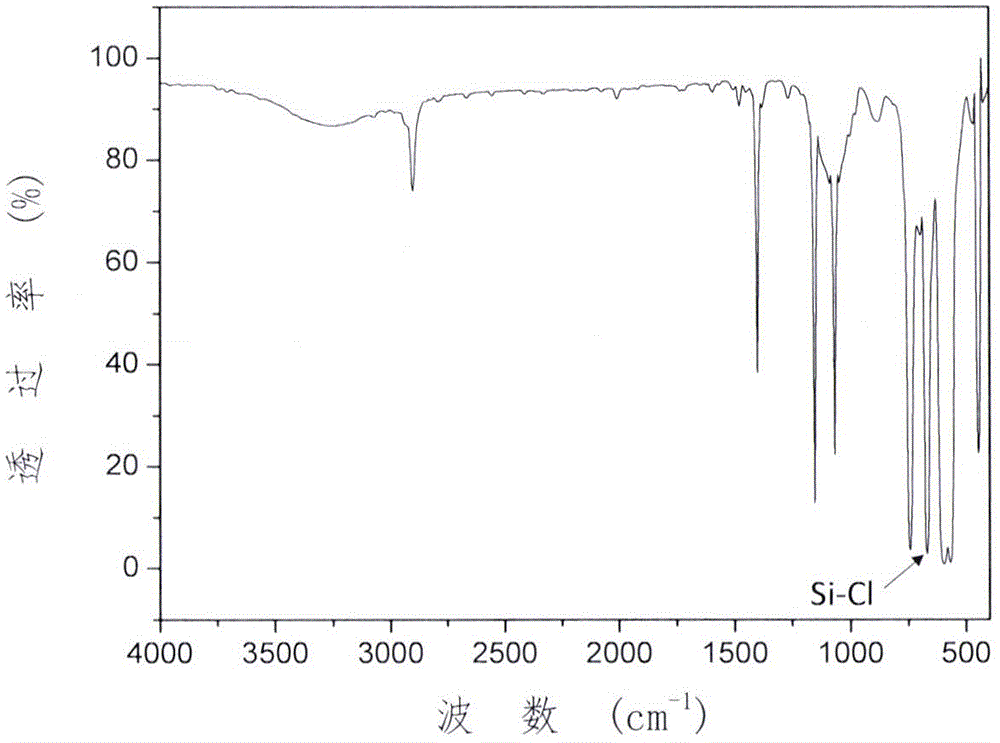

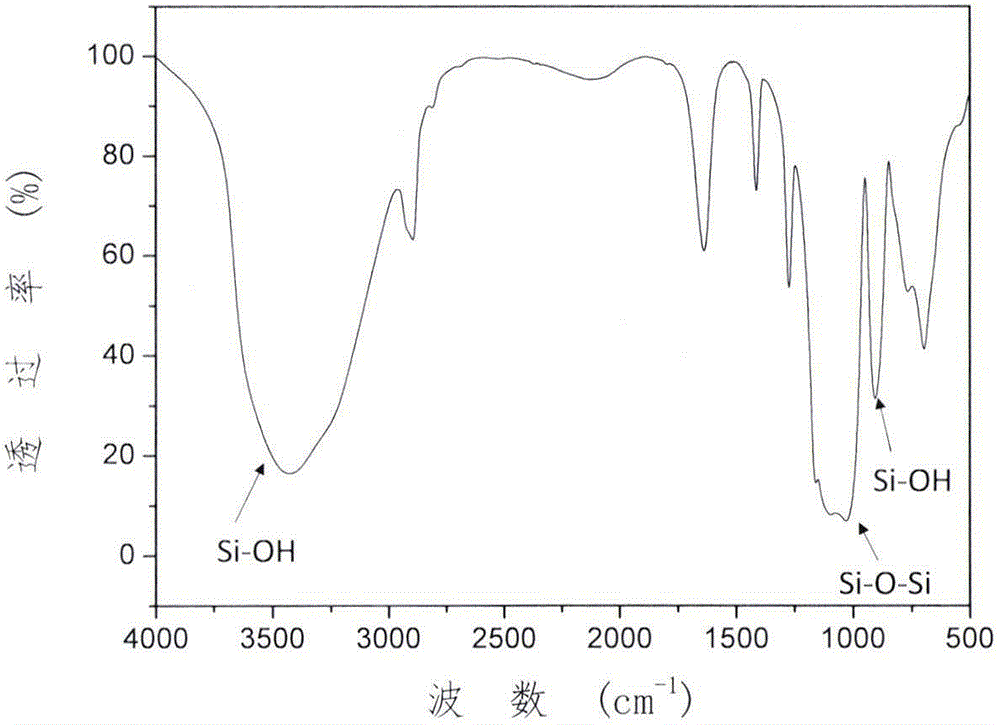

[0028] The characteristic functional groups of the substance were characterized by Nicolet5700 infrared spectromet...

Embodiment 1

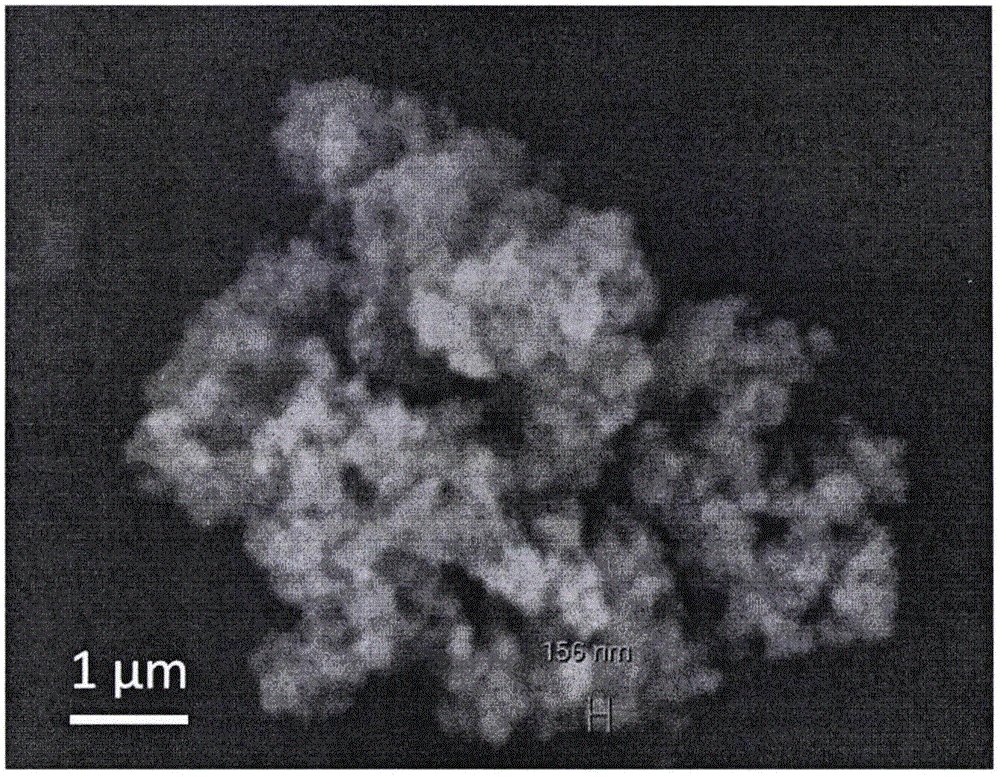

[0036] The water of 100 parts by weight is mixed with the ethanol of 10 parts by weight to prepare an aqueous alcohol solution and then added to the reactor, feed nitrogen and stir to remove the HCl generated by the reaction, control the reaction temperature at 20 degrees Celsius, and mix 10 parts by weight of bis(trichloro Silica) ethane was added dropwise into the reactor for reaction within 30 minutes. After the dropwise addition, 50 parts by weight of ethanol was added to continue the reaction for 20 minutes, and the precipitate obtained was filtered, washed with water, and dried to obtain an organic-inorganic hybrid silicone resin Nanoparticles. Compared figure 1 and figure 2 It can be seen that after the reaction finishes, the Si-Cl bond characteristic peak of the raw material bis(trichlorosilyl)ethane disappears, and the Si-O-Si and Si-OH group bond characteristic peaks are obvious, at 1130-1000cm -1 A broad and complicated peak appeared, indicating that the Si band ...

Embodiment 2

[0038] The water of 50 parts by weight is mixed with the ethanol of 50 parts by weight to prepare an aqueous alcohol solution and then added to the reactor, feed nitrogen and stir to remove the HCl generated by the reaction, control the reaction temperature at 20 degrees Celsius, and add 30 parts by weight of bis(trichloro Silyl) ethane was added dropwise into the reactor for reaction within 60 minutes. After the dropwise addition, 10 parts by weight of n-butanol was added to continue the reaction for 30 minutes, and the precipitate obtained was filtered, washed with water, and dried to obtain an organic-inorganic hybrid Silicone resin nanoparticles with an average particle size of 310nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com