Device and method for producing synthesis gas through superheated steam, pure oxygen, high-temperature reheated pyrolyzed garbage and biomass

A technology of superheated steam and synthesis gas, which is applied in the manufacture of combustible gas, gasification process, gas dust removal, etc., can solve the problems of not adopting the high temperature reheating process of synthesis gas, low combustion value of synthesis gas, and no rational utilization, etc. The effect of producing tar and dioxin, reducing oxygen consumption for combustion, and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

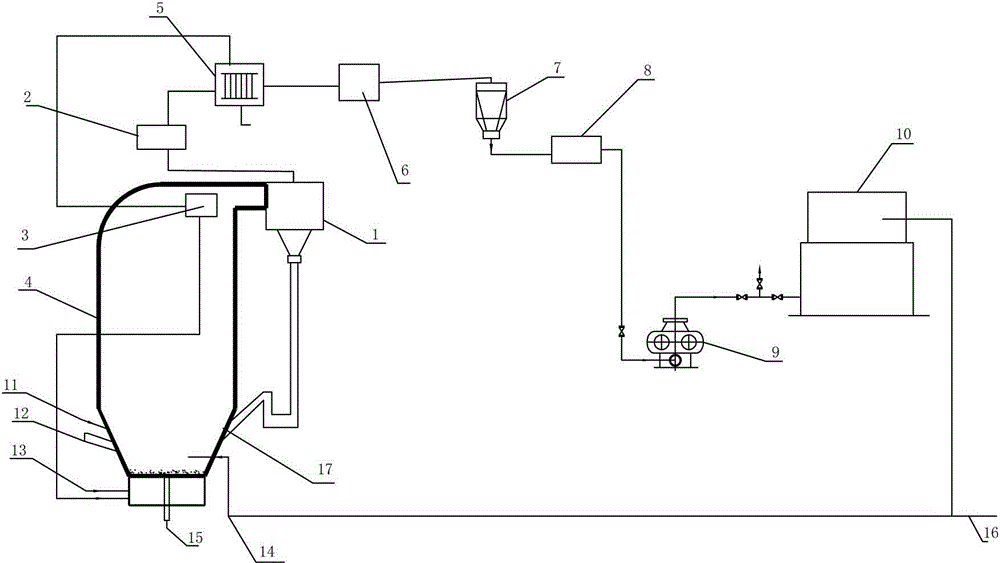

[0038] A device using superheated steam, pure oxygen, high-temperature reheating pyrolysis garbage and biomass to produce synthesis gas, comprising a fluidized bed pyrolysis furnace 4, a cyclone dust collector 1, the air outlet of the fluidized bed pyrolysis furnace 4 and The air inlet of the cyclone dust collector 1 is connected, and the ash discharge pipe of the cyclone dust collector 1 is connected with the return port 17 of the fluidized bed pyrolysis furnace 4 through a pipeline, and leads into the furnace, and the air outlet of the cyclone dust collector 1 Connected to the high-temperature reheater 2 through pipelines, the high-temperature reheater 2 is connected to the waste heat boiler 5 through pipelines, the waste heat boiler 5 is connected to the quench cooler 6 through pipelines, and the quench cooler 6 is connected to the dust collector 7 through pipelines ,

[0039] The quench cooler 7 is connected with a scrubber 8 through a pipeline, the scrubber 8 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com