A method for rapid preparation of large-area perovskite crystals

A perovskite, large-area technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of slow crystal growth, unfavorable large-scale preparation, low yield, etc., and the method is simple and easy to implement. , high yield, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) 2.5mmol of PbI 2 powder and 2.5 mmol CH 3 NH 3 I Mix the powder into a 5mL glass bottle, add 2.5mL of 1,4-butyrolactone, shake well, heat and stir in a constant temperature oven at 60°C until the powder is completely dissolved;

[0033] (2) Take 1mL of simethicone oil and place it in a 5mL beaker, and heat the beaker on a hot stage at 150°C;

[0034] (3) After the powder in the glass bottle in the first step is completely dissolved, take 10 μL of the perovskite solution and add it to the simethicone oil, and black crystals are formed immediately after 30 seconds.

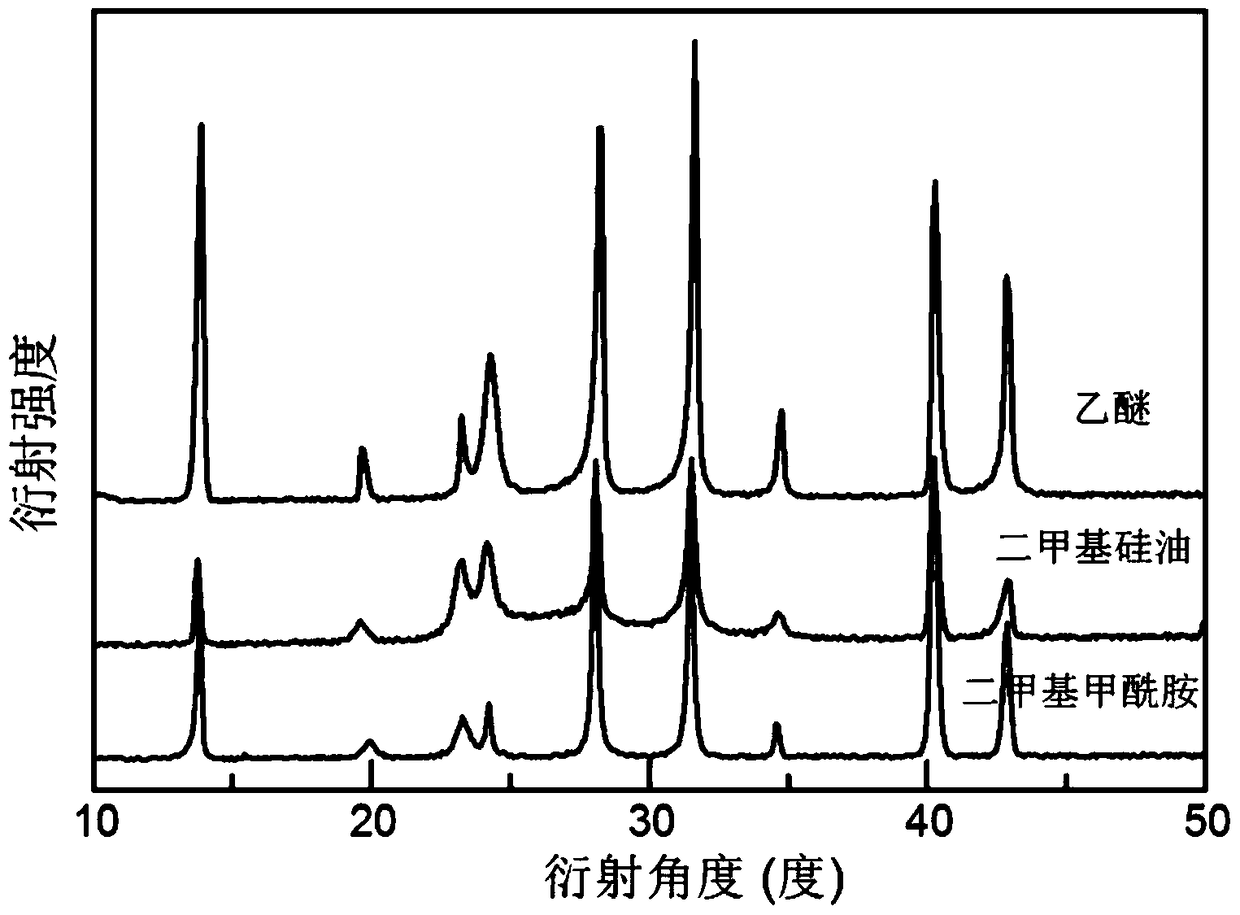

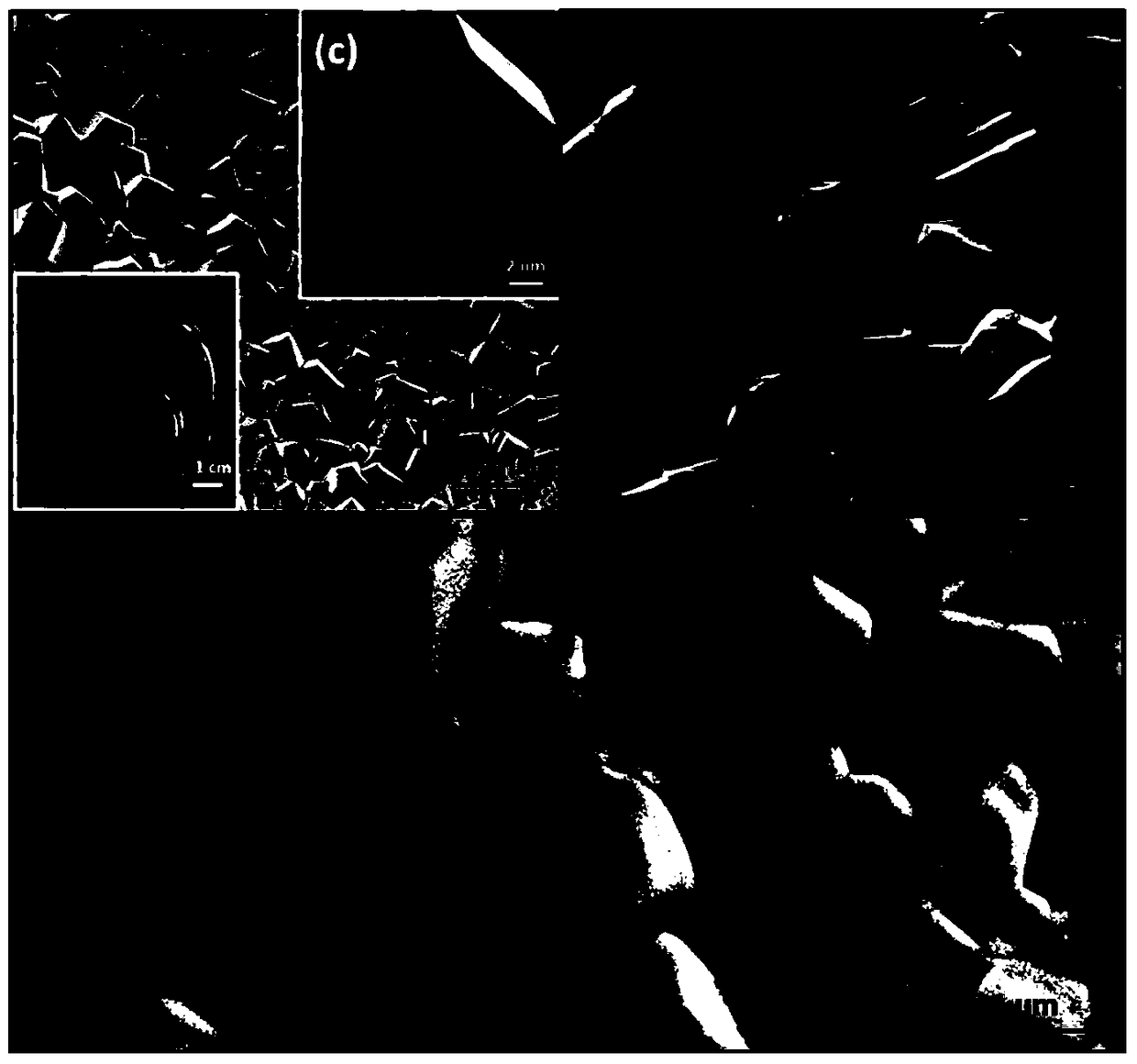

[0035] Carry out X-ray diffraction pattern analysis to the black crystal gained in embodiment 1 (as figure 1 ), SEM and optical photographs (such as figure 2 In (a), (c), (e)) analysis, it was confirmed that the grown black crystal was a perovskite crystal material.

Embodiment 2

[0037] (1) 2.5mmol of PbI 2 powder and 2.5 mmol CH 3 NH3 I Mix the powder into a 5mL glass bottle, add 2.5mL of 1,4-butyrolactone, shake well, heat and stir in a constant temperature oven at 60°C until the powder is completely dissolved;

[0038] (2) Take 2mL of dimethylformamide solution and drop it into a 5mL beaker, while heating the beaker on a hot stage at 70°C;

[0039] (3) After the powder in the glass cup is completely dissolved in the first step, take 5 μL of the perovskite solution and drop it into the dimethylformamide solution, and black crystals will form within 24 seconds.

[0040] Carry out X-ray diffraction pattern analysis to the black crystal gained in embodiment 2 (as figure 1 ) and SEM photographs (such as figure 2 In (b)) analysis, it was confirmed that the grown black crystal was a perovskite single crystal material.

Embodiment 3

[0042] (1) 2.5mmol of PbI 2 powder and 2.5 mmol of CH 3 NH 3 I Mix the powder into a 5mL glass bottle, add 2.5mL of 1,4-butyrolactone, shake well, heat and stir in a constant temperature oven at 60°C until the powder is completely dissolved;

[0043] (2) Take 1.5mL ether solution and drop it into a 5mL beaker without heating the beaker;

[0044] (3) After the powder in the glass cup is completely dissolved in the first step, take 15 μL of the perovskite solution and drop it into the ether solution, and black crystals will form within 26 seconds.

[0045] Carry out X-ray diffraction pattern analysis to the black crystal gained in embodiment 3 (as figure 1 ) and SEM photographs (such as figure 2 In (f)) analysis, it was confirmed that the grown black crystal was a perovskite single crystal material.

[0046] As can be seen from Example 1, Example 2 and Example 3, the preparation method of the perovskite crystal provided by the present invention has a crystal growth time of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com