Vanadium disulfide/graphene composite material and preparation method therefor

A composite material, vanadium disulfide technology, used in nanotechnology for materials and surface science, secondary batteries, electrochemical generators, etc., can solve problems such as low conductivity and low volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First, the preparation of graphene oxide is as follows: 20 mL of 98% concentrated sulfuric acid is added to the Erlenmeyer flask, and after being cooled to room temperature, it is placed in an ice-water bath at 0° C. to continue cooling until the temperature is lower than 4° C., and 2 mmol of natural flake graphite and Add 0.56mmol sodium nitrate to cold concentrated sulfuric acid, stir continuously in a magnetic stirrer to dissolve it completely, add 0.05mmol potassium permanganate to the above solution to obtain mixed solution B, stir for 2h; heat the temperature of mixed solution B to 35 Continue to stir for 30 min at ℃; then, add 40 mL of deionized water to the mixed solution B, raise the temperature to 90 °C and stir for 1 h, then add 4 mL of 30% hydrogen peroxide and stir for 10 min; to obtain the reaction product, centrifuge the reaction product with 1M HCl, deionized water and acetone respectively Wash several times to obtain graphene oxide sheets;

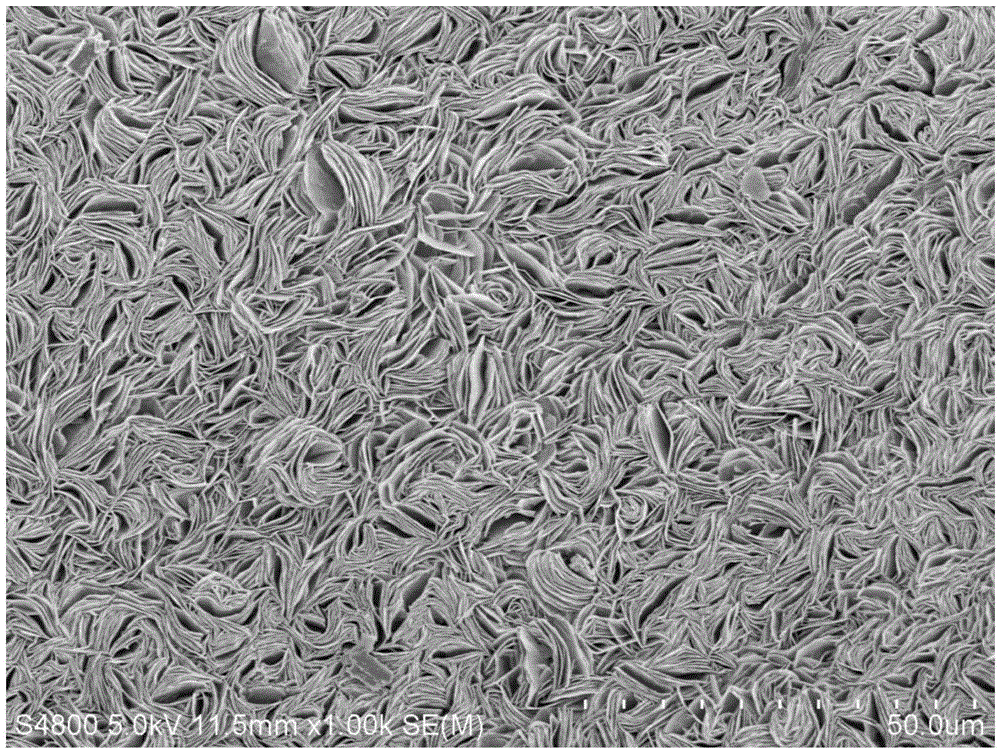

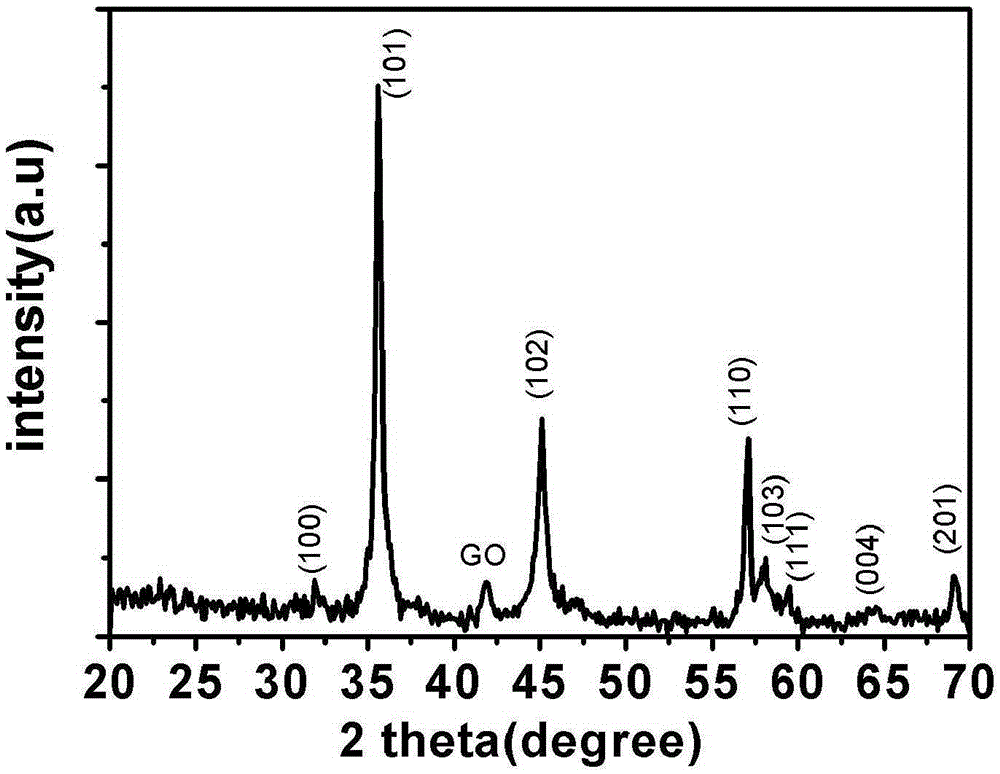

[0029] Seco...

Embodiment 2

[0035] First, the preparation of graphene oxide is specifically: 20mL98% concentrated sulfuric acid is added in the Erlenmeyer flask, after cooling, it is placed in an ice-water bath at 0°C, 4mmol of natural flake graphite and 0.112mmol of sodium nitrate are added to the cold concentrated sulfuric acid, Stir continuously in a magnetic stirrer to dissolve completely, add 0.1mmol potassium permanganate to the above solution, stir for 2h; raise the temperature to 35°C and continue stirring for 30min; then, add 40mL deionized water, heat up to 90°C and stir 1h, then add 4mL of 30% hydrogen peroxide and stir for 10min; finally, wash with 1M HCl, deionized water and acetone for several times to obtain graphene oxide sheets;

[0036] Second, make VS 2 / Graphene composite material: 2mmol ammonium metavanadate (NH 4 VO 3 ) into 15mL of deionized water, then adjust the pH value of the solution by adding 3mL of ammonia water, and continuously stir with a magnetic stirrer to completely ...

Embodiment 3

[0040] First, for the preparation of graphene oxide, add 20mL of 98% concentrated sulfuric acid into the Erlenmeyer flask, place it in an ice-water bath at 0°C after cooling, add 1mmol of natural flake graphite and 0.28mmol of sodium nitrate into the cold concentrated sulfuric acid, and stir under magnetic force Stir continuously in the container to dissolve it completely, add 0.025mmol potassium permanganate to the above solution to obtain mixed solution B, stir for 2h; raise the temperature to 35°C and continue stirring for 30min; then, add 40mL deionized water and heat up to 90°C Stir for 1 hour, then add 4 mL of 30% hydrogen peroxide and stir for 10 minutes; finally, wash with 1M HCl, deionized water and acetone for several times to obtain graphene oxide sheets;

[0041] Second, make VS 2 / Graphene composite material: 2mmol ammonium metavanadate (NH 4 VO 3 ) into 15mL of deionized water, then adjust the pH value of the solution by adding 3mL of ammonia water, and continu...

PUM

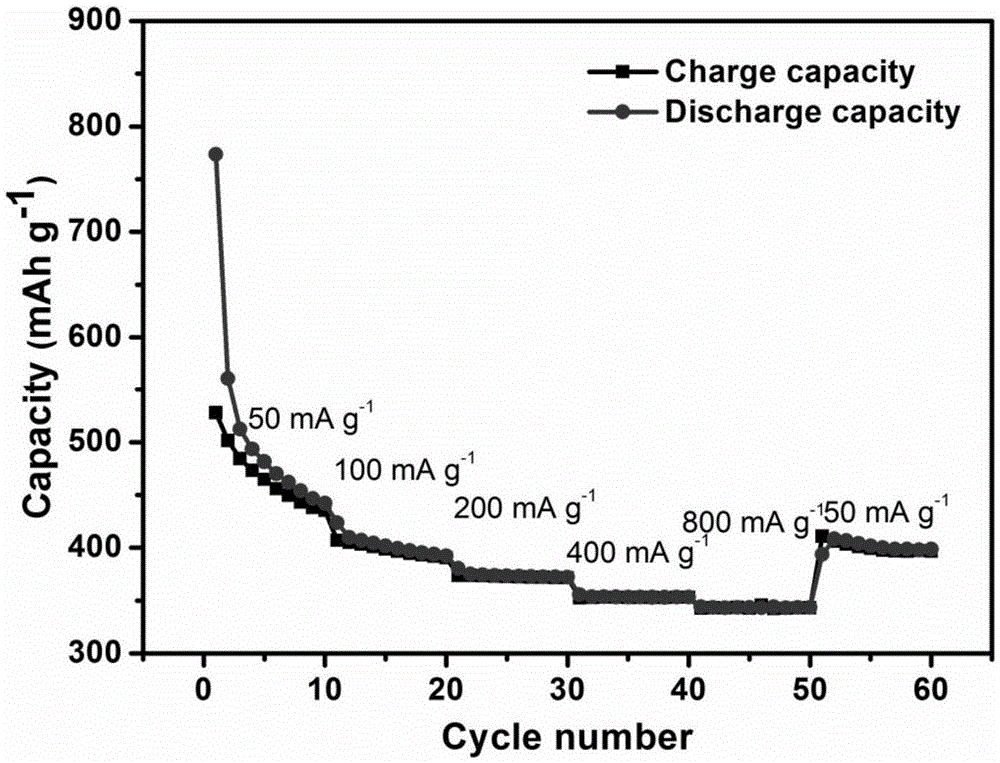

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com