Method for modifying surfaces of gold nanoparticles through ionic liquid

A gold nanoparticle, ionic liquid technology, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve the problems of difficult operation, complicated experimental scheme, and traditional methods take a long time, and achieve the goal of reducing biological toxicity and method. Simple, efficient, safe, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

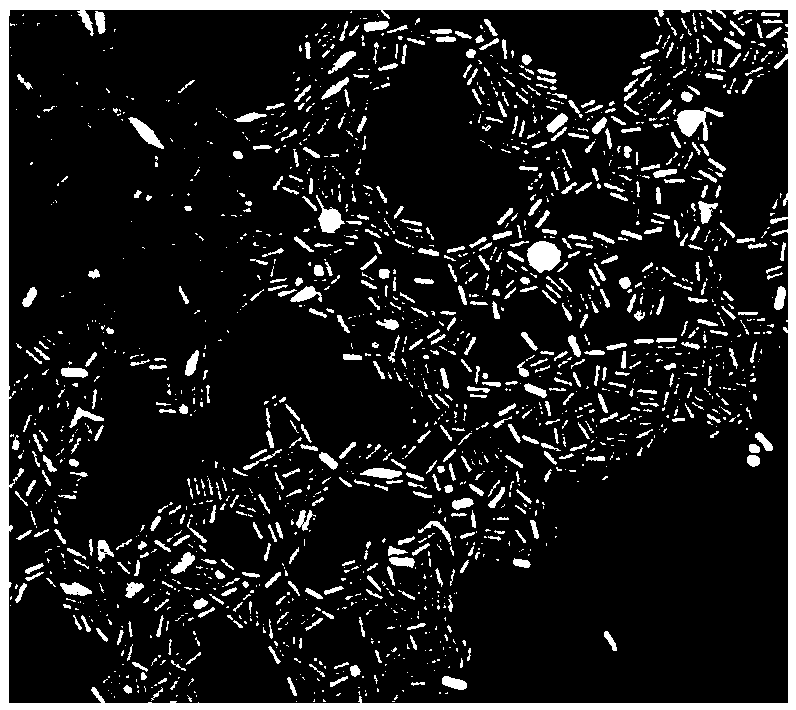

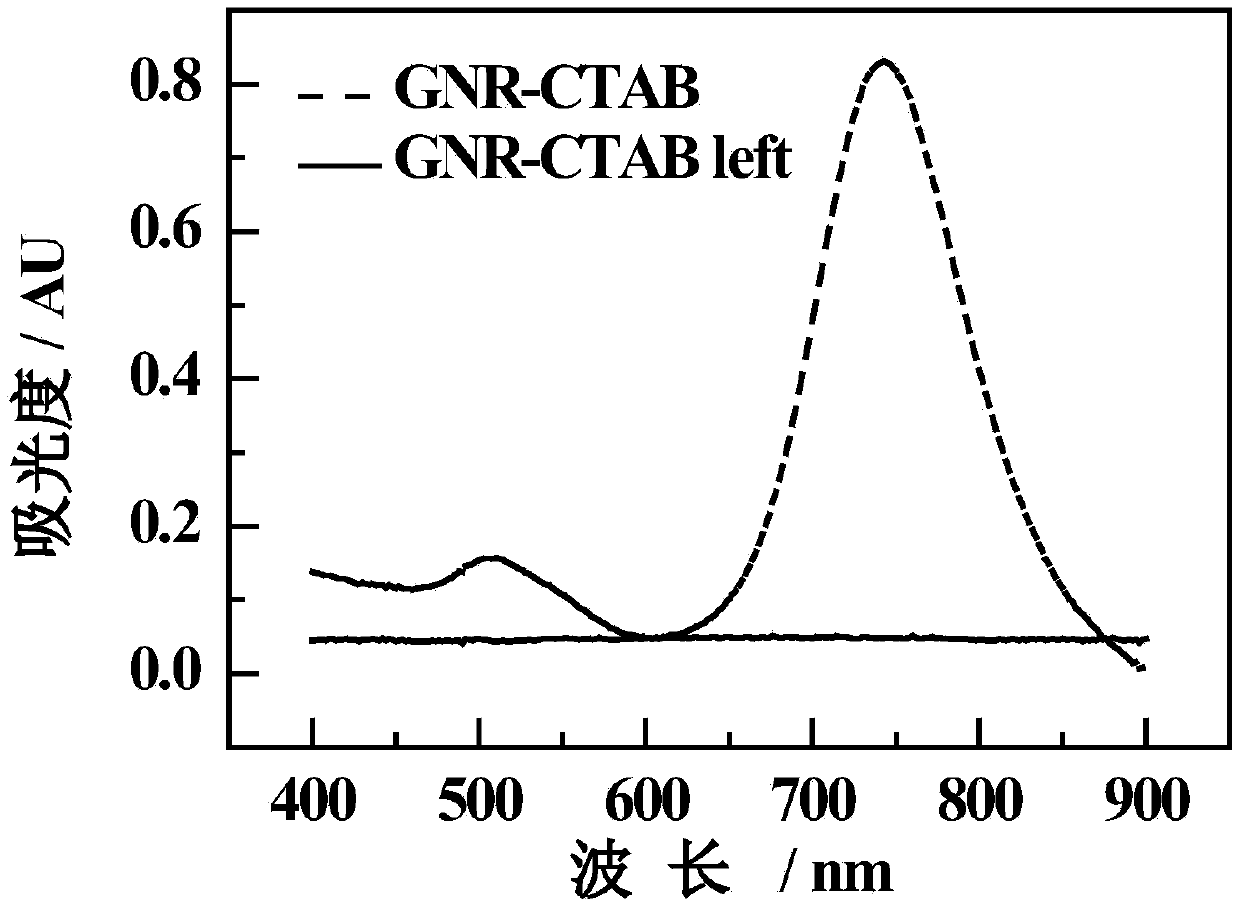

[0071] Firstly, the preparatory step is carried out: GNRs with uniform size and good dispersion are prepared by the classic seed growth method ( Figure 1a ):

[0072] (1) Gold seed preparation: Add 5 mL of 0.5 mM chloroauric acid (HAuCl) to 5 mL of 0.2 M CTAB aqueous solution 4 ) solution, and mix well. Quickly add 0.6 mL of 10 mM ice-cold sodium borohydride (NaBH 4 ) solution, after the addition is complete, mix evenly, put it statically in a water bath at 27°C, and finish the reaction after 2-3 hours, and confirm it by ultraviolet-visible spectroscopy.

[0073] (2) Preparation of GNRs: Add 5 mL of 1 mM HAuCl to 5 mL of 0.2 M CTAB aqueous solution 4 aqueous solution, and then mix well. Add 0.2 mL of silver nitrate (AgNO 3 ) solution, shake by hand to mix well. Continue to add 70 μl of ascorbic acid (AA) aqueous solution with a concentration of 78.8 mM to the above solution, and shake it by hand to mix evenly, so that the color of the solution becomes colorless. Then a...

no. 2 example

[0096] One-step green and efficient surface functionalization modification of GNRs in ionic liquids.

[0097] Preliminary step, using the classic seed growth method to prepare GNRs with uniform size and good dispersion ( Figure 1a ), specific method with reference to embodiment one.

[0098] Next, GNRs were modified by surface functionalization in ionic liquids:

[0099] Step (1), preparing an aqueous phase gold nanoparticle solution. In this step, the above-mentioned 1.5mL prepared GNRs were transferred to a centrifuge tube, and centrifuged twice at 12000rpm / 20min at a temperature of 25-60°C. Pure water or pH 5.5-7.0 phosphate buffer solution for redispersion.

[0100] Step (2), dissolving MUA into ionic liquid to obtain a 2.35mM 150μL reaction system. Then, 100 μL of LGNRs in step (1) was added dropwise to the reaction system under the condition of vigorous vortexing at 3000 rpm (MUA / [BMIM]Tf 2 N).

[0101] Step (3), when all GNRs are transferred from the aqueous phas...

no. 3 example

[0105] Two-step green and efficient surface functionalization modification of GNRs in reusable ionic liquids.

[0106] Preliminary steps: GNRs with uniform size and good dispersion were prepared by classical seed growth method ( Figure 1a ), the specific method refers to the first embodiment.

[0107] Next, GNRs were modified by surface functionalization in ionic liquids:

[0108] Step (1), preparing an aqueous phase gold nanoparticle solution. First, transfer the above 1.5mL prepared GNRs to a centrifuge tube, perform two centrifugation at 12000rpm / 20min at a temperature of 25-60°C, remove the supernatant after centrifugation, and wash the remaining part with 100μL ultrapure water Or phosphate buffer solution (PH5.5-7.0) to re-disperse.

[0109] Step (2), 100 μ LGNRs in step (1) is transferred to the ionic liquid ([BMIM]Tf 2 N).

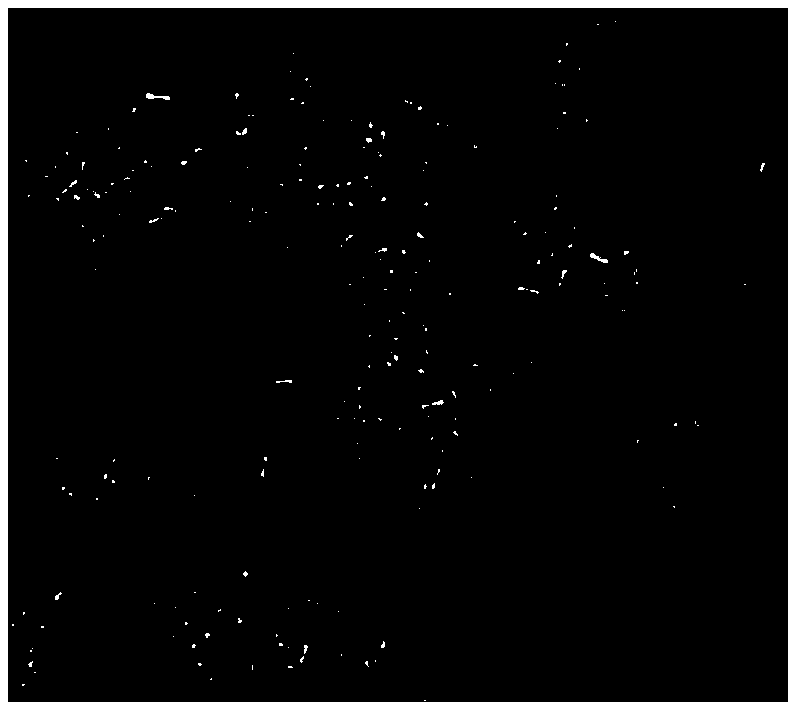

[0110] Step (3), when all GNRs are transferred from the aqueous phase to [BMIM]Tf 2 After N phase ( figure 2 ), plus surface modification m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com