Preparation method of magnesium sulfate heptahydrate

A technology of magnesium sulfate heptahydrate and sodium sulfate, applied in the direction of magnesium sulfate, etc., can solve the problems of production equipment corrosion, environmental pollution, and waste by-products, and achieve the effects of less equipment corrosion, less environmental pollution, and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. Examples of these preferred embodiments are illustrated in the accompanying drawings. The embodiments of the invention shown in and described with reference to the drawings are merely exemplary, and the invention is not limited to these embodiments.

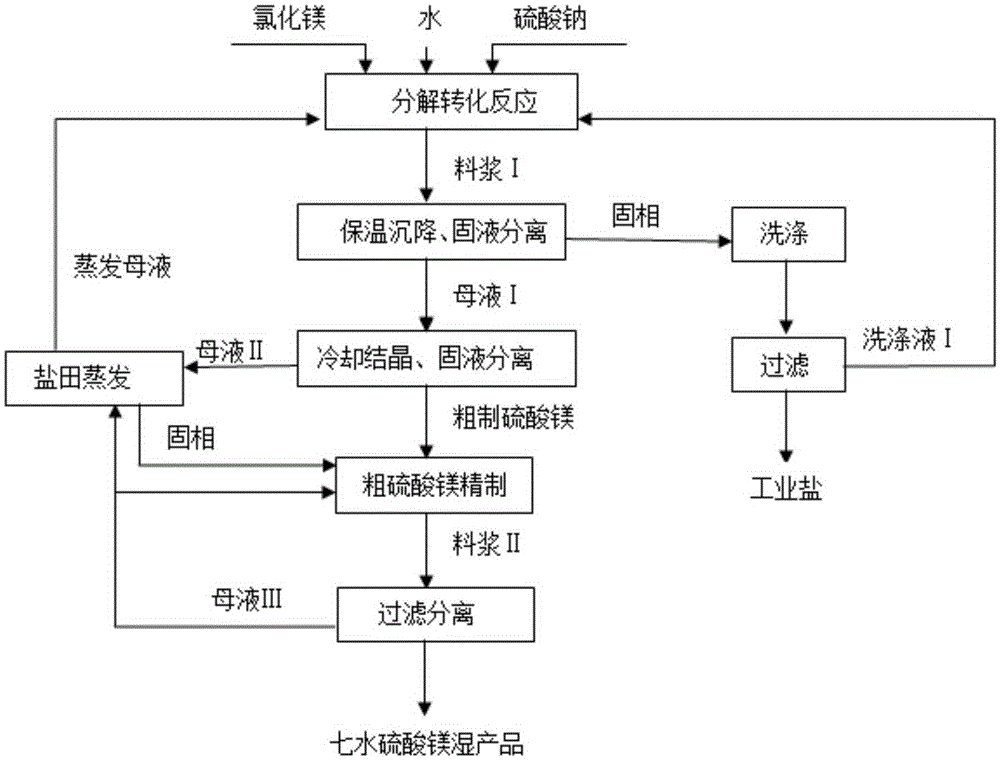

[0023] refer to figure 1 Process flow diagram, the preparation method of magnesium sulfate heptahydrate provided in the embodiments of the present invention mainly comprises steps:

[0024]Step A, sodium sulfate, magnesium chloride and fresh water are mixed according to the weight ratio of 1: (3-6): (1.5-3.5) and the ingredients are decomposed and transformed to obtain slurry I; wherein, the sodium sulfate can be Glauber's salt (Yuan Mingfen) or water-containing Glauber's salt; The magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com