2-methyl-3-alkyl imidazole onium salt polyarylether comb type polymer and preparation and application thereof

A technology of comb polymer and bromomethylated polyarylether, which is applied in the field of comb polymer and its preparation, can solve the problems of low ion conductivity and poor alkali resistance of quaternary ammonium groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: 2-methyl-3-hexyl imidazolium salt polyaryl ether sulfone comb polymer and preparation method thereof

[0042] (1) Preparation of bromomethylated polyaryl ether sulfone: Dissolve 15 g of tetramethylbiphenol type polyaryl ether sulfone in 200 mL of chloroform, add to 500 mL of N 2 In a protected three-necked flask, heat to 70°C under mechanical stirring. 11.75g of N-bromosuccinimide and 1.6g of benzoyl peroxide were added to the reaction system twice. The reaction was continued for 24h, and discharged in acetone after cooling. The strips are pulverized with a high-speed pulverizer, and then the polymer is boiled and washed with distilled water, filtered, and repeated 6 times, and then dried in a vacuum oven to obtain the product.

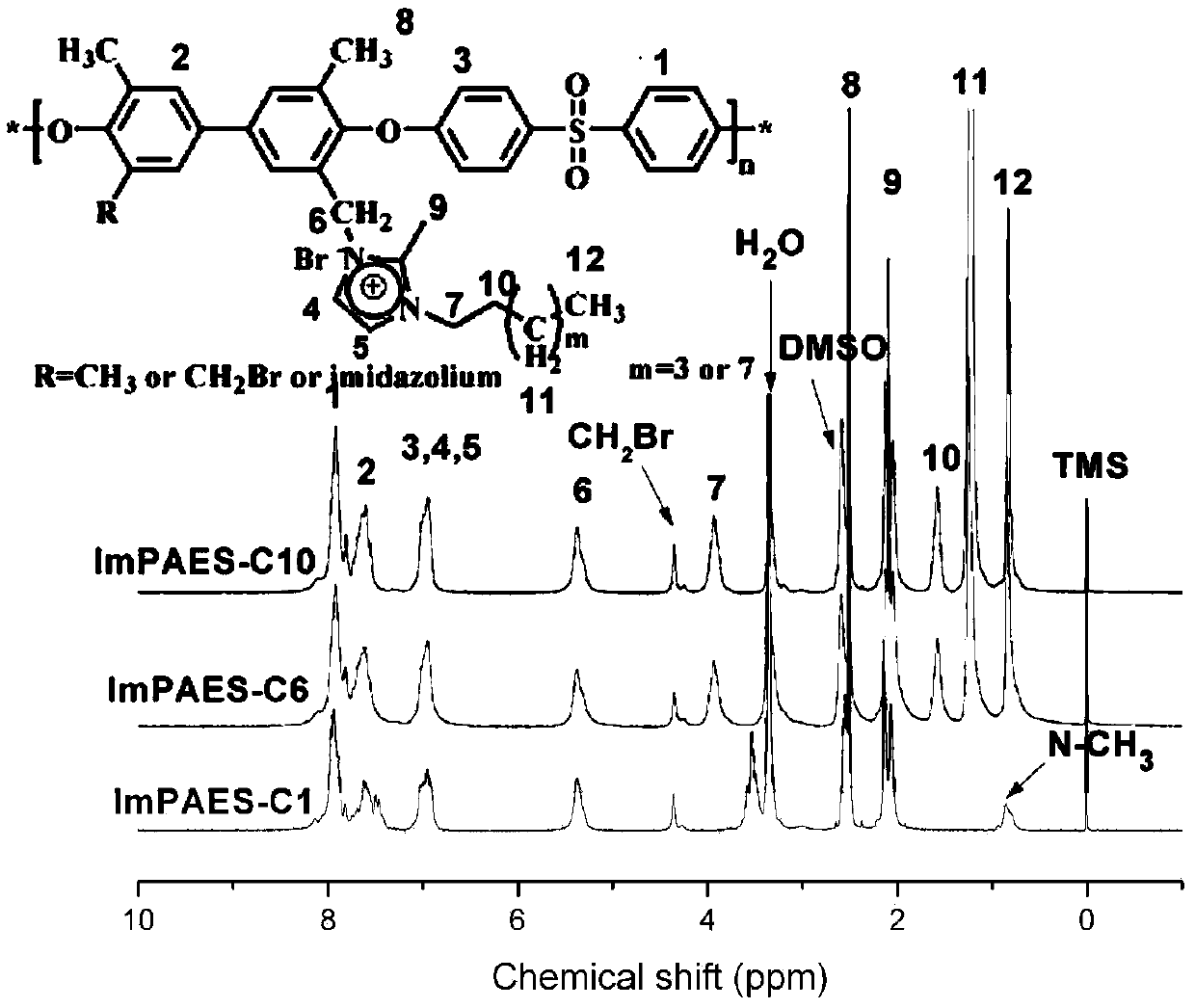

[0043] The peak at 4.5ppm in the NMR spectrum corresponds to the hydrogen on the benzyl bromide carbon (Ar-CH 2 -Br), the peak at 2.2 ppm corresponds to hydrogens on residual methyl groups that did not participate in the brom...

Embodiment 2

[0048] Example 2: 2-methyl-3-decyl imidazolium salt polyarylethersulfone comb polymer and its preparation method

[0049] (1) Preparation of bromomethylated polyaryl ether sulfone: same as Example 1.

[0050] (2) Preparation of 1-decyl-2-methylimidazole: 2.46g of 2-methylimidazole, 5.97g of 1-bromodecane and 1.8g of sodium hydroxide were dissolved in 70mL of acetonitrile, heated and stirred at 60°C for 12h , continuous access to N 2 Protect. After the reaction was completed, it was cooled to room temperature, and the precipitate was filtered off. The acetonitrile solvent was removed with a rotary evaporator to obtain the crude product as an oil. The crude product was dissolved in 70mL of dichloromethane, washed four times with water, separated, dried with anhydrous magnesium sulfate for 48h, and obtained by filtration.

[0051] The obtained 1-decyl-2-methylimidazole is subjected to structure determination by nuclear magnetic resonance spectrum, and the result is obtained: ...

Embodiment 3

[0054] Embodiment 3: Preparation of dimethylimidazolium salt polyarylethersulfone polymer

[0055] Completely dissolve 3g of bromomethylated polyarylethersulfone with a bromination degree of 1.75 in 30mL of N-methylpyrrolidone, then add 1.01g of 1,2-dimethylimidazole into the reaction solution, N 2 Protected, mechanically stirred, and heated at 60°C for 12h. After cooling, the material was discharged in acetone, crushed, filtered, washed 5 times with water, and dried to obtain bromo-type dimethylimidazolium salt polyarylethersulfone polymer (ImPAES-C1).

[0056] figure 1 In the NMR spectrum shown, the peak at 0.8 ppm corresponds to the hydrogen on the N3 methyl group of the grafted imidazole ring, thus proving the successful introduction of the dimethylimidazolium group. By calculating the residual hydrogen in the benzyl bromine position in the nuclear magnetic spectrum, the calculated reaction conversion rate is also 74%. The glass transition temperature of ImPAES-C1 measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com