Method for preparing base-region graded doped silicon carbide thin film epitaxy layer

A silicon carbide and silicon carbide substrate technology, applied in gaseous chemical plating, metal material coating process, superimposed layer plating and other directions, can solve problems affecting device performance, high bond strength of silicon carbide, lattice damage, etc. , to simplify the preparation process, improve device performance, and achieve the effect of complete lattice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

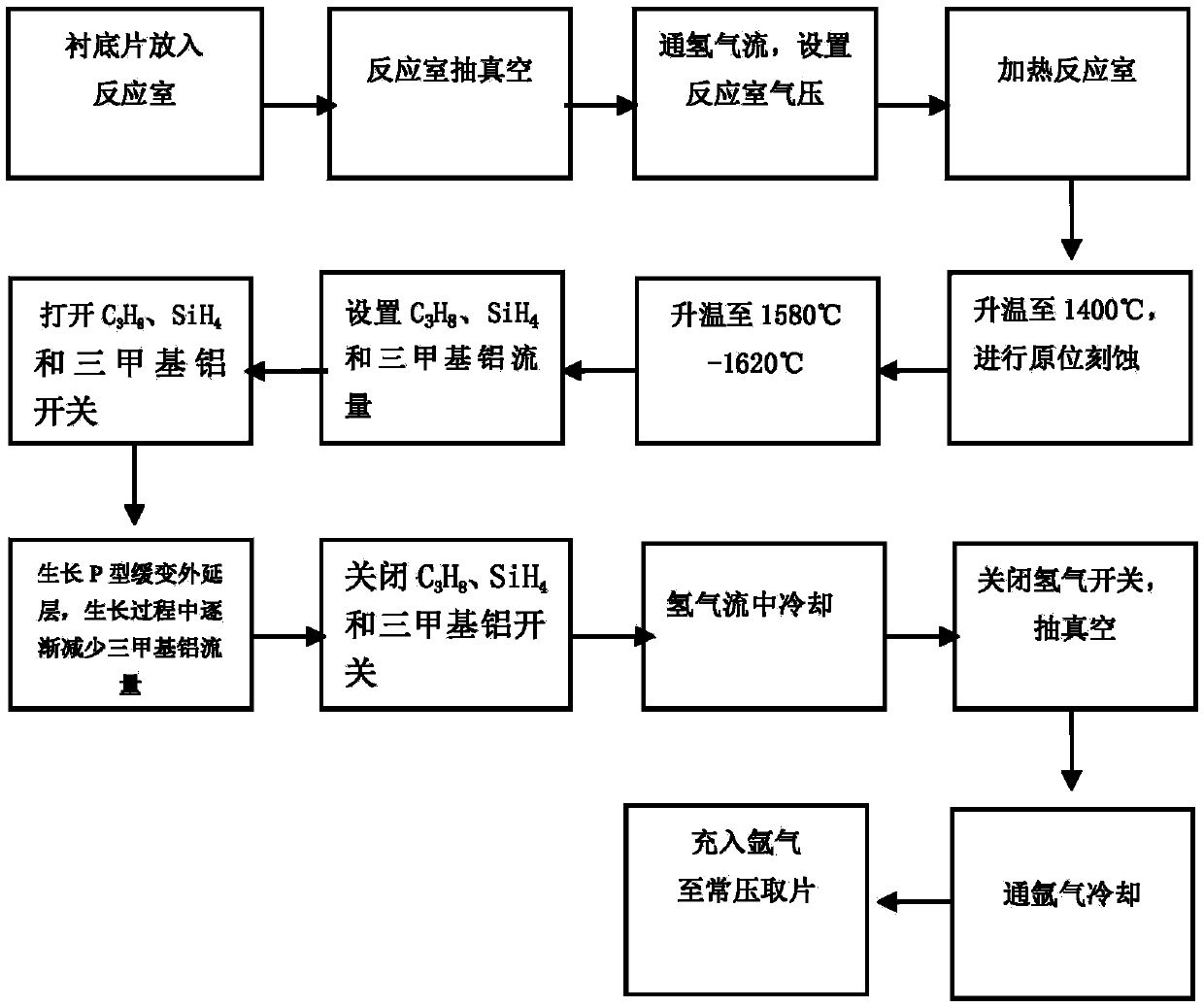

Image

Examples

Embodiment 1

[0043] In step 1, the silicon carbide substrate is placed in the reaction chamber of the silicon carbide CVD equipment.

[0044] (1.1) Selection bias Crystal orientation 4° (bias The crystal orientation 4° refers to the 4H silicon carbide substrate with a deviation of 4° in the 11-20 direction in the 0001 direction, and is placed in the reaction chamber of the silicon carbide CVD equipment;

[0045] (1.2) Evacuate the reaction chamber until the pressure of the reaction chamber is lower than 1×10 -7 mbar.

[0046] In the second step, the reaction chamber is heated in a hydrogen stream.

[0047] (2.1) Open the hydrogen switch leading to the reaction chamber, and control the hydrogen flow to gradually increase to 60L / min;

[0048] (2.2) Turn on the vacuum pump to extract the gas in the reaction chamber, and keep the pressure of the reaction chamber at 100mbar;

[0049] (2.3) Gradually increase the power of the heating source to slowly increase the temperature of the reacti...

Embodiment 2

[0066] In step 1, the silicon carbide substrate is placed in the reaction chamber of the silicon carbide CVD equipment.

[0067] (1.1) Selection bias Crystal orientation 8° (bias The crystal orientation of 8° refers to the 4H silicon carbide substrate that deviates from the 11-20 direction by 8° in the 0001 direction, and is placed in the reaction chamber of the silicon carbide CVD equipment;

[0068] (1.2) Evacuate the reaction chamber until the pressure of the reaction chamber is lower than 1×10 -7 mbar.

[0069] In the second step, the reaction chamber is heated in a hydrogen stream.

[0070] (2.1) Open the hydrogen switch leading to the reaction chamber, and control the hydrogen flow to gradually increase to 60L / min;

[0071] (2.2) Turn on the vacuum pump to extract the gas in the reaction chamber, and keep the pressure of the reaction chamber at 100mbar;

[0072] (2.3) Gradually increase the power of the heating source to slowly increase the temperature of the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com