A collagen-based cartilage scaffold

A collagen and cartilage technology, applied in medical science, prostheses, tissue regeneration, etc., can solve the problems of back layer separation, poor biocompatibility, cartilage ossification, etc., to achieve increased mechanical properties, complete double-layer structure, The effect of tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

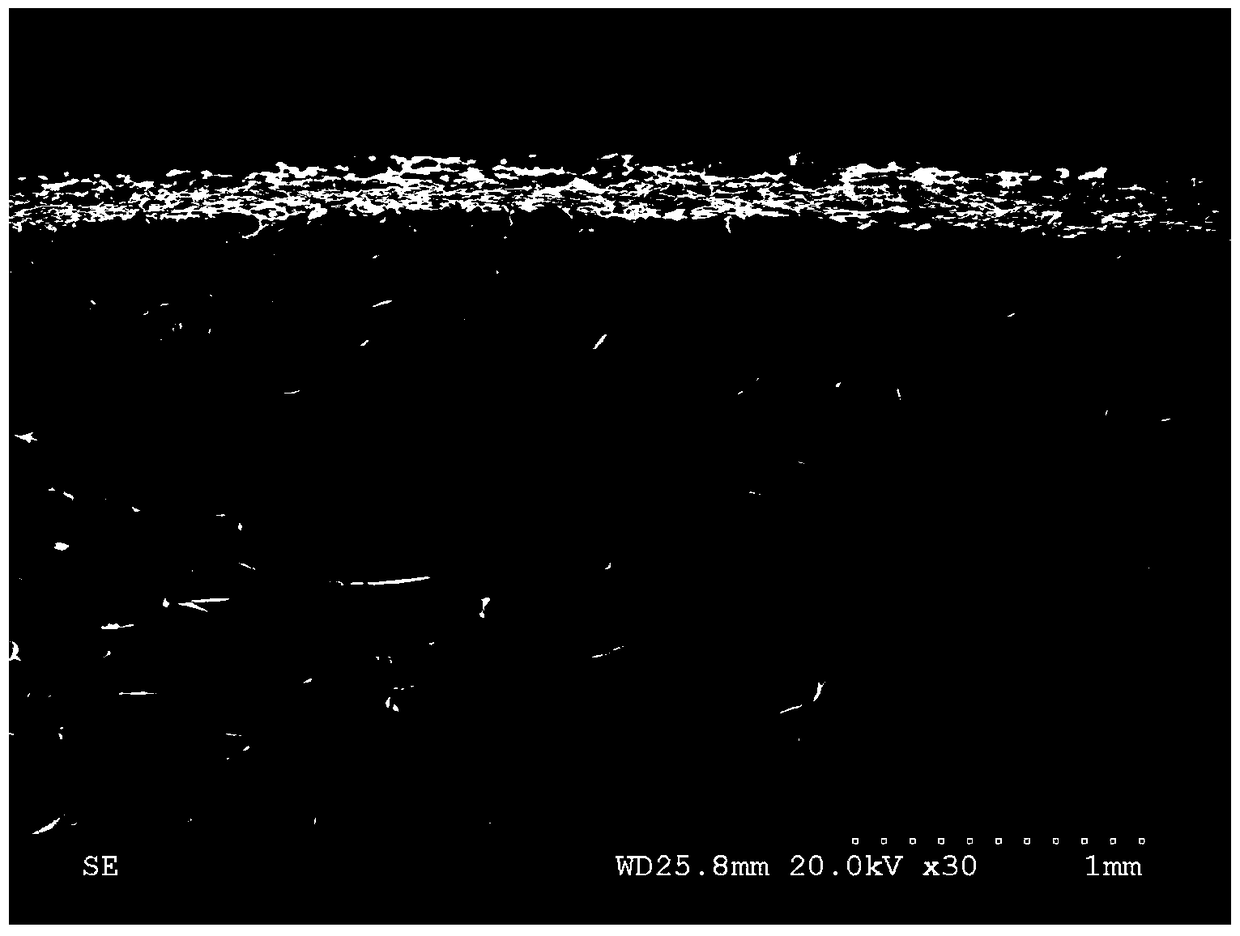

Embodiment 1

[0022] (1) Spread the collagen solution with a concentration of 20mg / ml into a polytetrafluoroethylene grooved mold with a size of 100mm×100mm×5mm, and freeze at -20°C for 16 hours to form.

[0023] (2) Immerse the frozen collagen into a phosphate buffer solution (disodium hydrogen phosphate (Na 2 HPO 4 ) 2.436g / L and potassium dihydrogen phosphate (KH 2 PO 4 ) 0.8g / L, adjust the pH to 7.4) for 24 hours.

[0024] (3) Extrude the dehydrated collagen as a whole with gradient pressure (70-80Kg for 30 seconds, 100-110Kg for 30 seconds, 140-150Kg for 30 seconds, 200-210Kg for 60 seconds) to form a film, and then spread the concentration on the dense film. 5mg / ml collagen solution to 5mm thickness.

[0025] (4) The whole double-layer collagen was frozen at -30°C for 16 hours, and then dried in a freeze dryer for 48 hours.

[0026] (5) The freeze-dried bilayer collagen was cross-linked with EDC-NHS (EDC and NHS concentrations were 20 mg / ml and 5 mg / ml, respectively) for 3 hours....

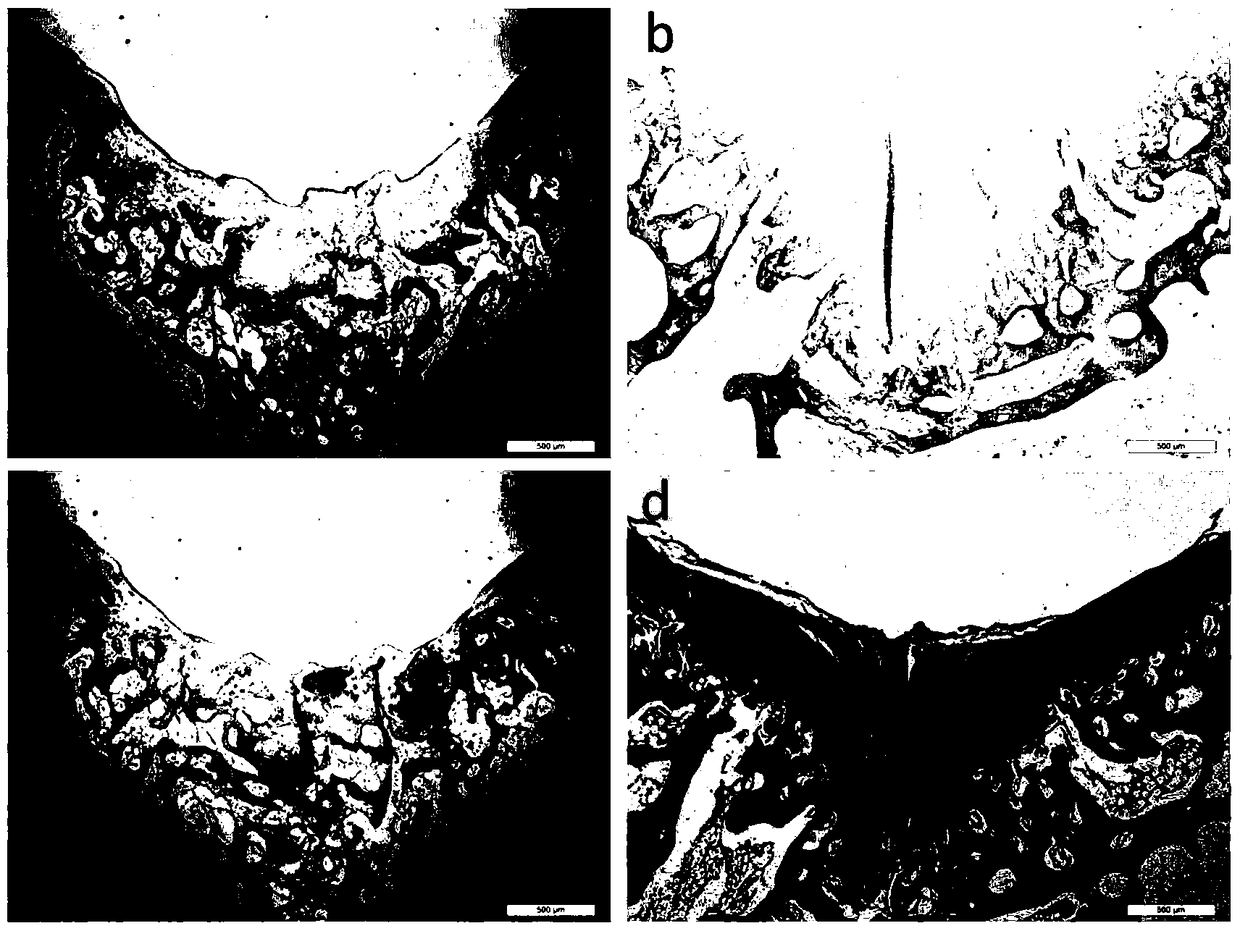

Embodiment 2

[0030] (1) Spread the collagen solution with a concentration of 5mg / ml into a polytetrafluoroethylene grooved mold with a size of 100mm×100mm×3mm, and freeze at -80°C for 12 hours to form.

[0031] (2) Immerse the frozen collagen in citric acid-disodium hydrogen phosphate buffer solution containing 50g / L NaCl concentration (containing citric acid 1.92g / L and disodium hydrogen phosphate 25.8g / L, adjust the pH to 8.0) 12 hours.

[0032] (3) Extrude the dehydrated collagen as a whole with gradient pressure (50-70Kg for 30 seconds, 100-110Kg for 30 seconds, 150-170Kg for 30 seconds, 200-250Kg for 30 seconds) to form a film, and spread the concentration on the dense film. 5mg / ml collagen solution to 3mm thickness.

[0033] (4) The whole double-layer collagen was frozen at -20°C for 8 hours, and then dried in a freeze dryer for 12 hours.

[0034] (5) The lyophilized bilayer collagen was cross-linked with glutaraldehyde at a concentration of 0.05% (w / v) for 8 hours.

[0035] (6) W...

Embodiment 3

[0038] (1) Spread the collagen solution with a concentration of 40mg / ml into a polytetrafluoroethylene grooved mold with a size of 100mm×100mm×8mm, and freeze at -30°C for 18 hours to form.

[0039] (2) The frozen collagen was immersed in Tris-hydrochloric acid buffer solution (containing Tris 6.057 g / L and 0.042 mol / L hydrochloric acid, pH adjusted to 7.0) containing KCl concentration 340 g / L for 24 hours.

[0040] (3) Extrude the whole dehydrated collagen with gradient pressure (80-100Kg for 30 seconds, 120-150Kg for 30 seconds, 180-200Kg for 30 seconds, 400-500Kg for 30 seconds) to form a film, and then spread it on the dense film with a concentration of 20mg / ml collagen solution to 8mm thickness.

[0041] (4) The whole double-layer collagen was frozen at -80°C for 20 hours, and then dried in a freeze dryer for 48 hours.

[0042] (5) The freeze-dried bilayer collagen was cross-linked with genipin at a concentration of 1 mmol / L for 6 hours.

[0043] (6) Wash the cross-link...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com