Preparing method of amino carbon quantum dot fluorescence silicon substrate imprint sensor

An amino carbon quantum and carbon quantum dot technology, which is applied in chemical instruments and methods, fluorescence/phosphorescence, luminescent materials, etc., to achieve the effects of large yield, high conversion rate, and easy and feasible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

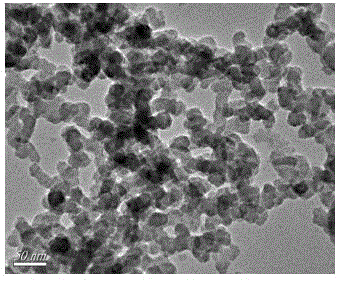

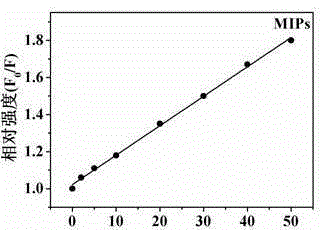

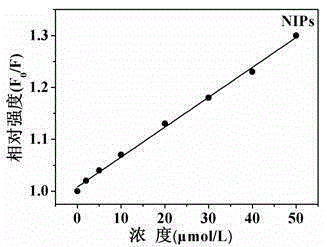

Image

Examples

Embodiment 1

[0027] (1) Add 2g of citric acid and 1g of polyethyleneimine into 30mL of deionized water, and fully dissolve to obtain a transparent solution. Then transfer the mixed solution to a hydrothermal reaction kettle with a volume of 50mL, place the reaction kettle in an oven, heat up to 160°C, react for 4 hours, and cool to room temperature to obtain aminocarbon quantum dots with high-performance fluorescent properties of the dispersion. The dispersion liquid is centrifuged, and the supernatant liquid is preserved to obtain an amino carbon quantum dot solution.

[0028] (2) Mix 50 μL aminocarbon quantum dot solution, 1 mL double distilled water and 7 mL ethanol into the flask, add 11.7 μL (3-aminopropyl) triethoxysilane and 3.5 mg p-nitrophenol at the same time, and stir for 20 min . Then 44.8 μL tetraethyl orthosilicate and 44.8 μL ammonia water were added to the above system and reacted for 10 hours. After the reaction, wash with water and ethanol several times to remove unrea...

Embodiment 2

[0031] (1) Add 2g of citric acid and 2g of polyethyleneimine into 40mL of deionized water, and fully dissolve to obtain a transparent solution. Then transfer the mixed solution to a hydrothermal reaction kettle with a volume of 50mL, place the reaction kettle in an oven, heat up to 200°C, react for 8 hours, and cool to room temperature to obtain aminocarbon quantum dots with high-performance fluorescent properties of the dispersion. Centrifuge the dispersion, save the supernatant, and use the amino carbon quantum dot solution.

[0032] (2) Mix 100 μL amino carbon quantum dot solution, 1 mL twice distilled water and 11 mL ethanol into the flask, add 70.2 μL (3-aminopropyl) triethoxysilane and 3.5 mg p-nitrophenol at the same time, stir 30min. Then 134.4 μL tetraethyl orthosilicate and 268.8 μL ammonia water were added to the above system and reacted for 14 hours. After the reaction, wash with water and ethanol several times to remove unreacted substances, and dry the product...

Embodiment 3

[0035] (1) Add 2g of citric acid and 1.5g of polyethyleneimine into 35mL of deionized water, and fully dissolve to obtain a transparent solution. Then transfer the mixed solution to a hydrothermal reaction kettle with a volume of 50mL, place the reaction kettle in an oven, heat up to 180°C, react for 6 hours, and cool to room temperature to obtain aminocarbon quantum dots with high-performance fluorescent properties of the dispersion. Centrifuge the dispersion, save the supernatant, and use the amino carbon quantum dot solution.

[0036] (2) Mix 80 μL of amino carbon quantum dot solution, 1 mL of double distilled water and 9 mL of ethanol into the flask, add 23.4 μL of (3-aminopropyl) triethoxysilane and 3.5 mg of p-nitrophenol at the same time, and stir 25min. Then 112 μL tetraethyl orthosilicate and 168 μL ammonia water were added to the above system and reacted for 12 hours. After the reaction, wash with water and ethanol several times to remove unreacted substances, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com