Preparation method for forming particle and short fiber gradient structure on surface of Ti-6Al-4V alloy

A ti-6al-4v, gradient structure technology, applied in the field of surface treatment, can solve the problems of high crack sensitivity, thin surface layer, difficult to form gradient structure, etc., and achieve the effect of smooth macroscopic appearance and dense coating structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

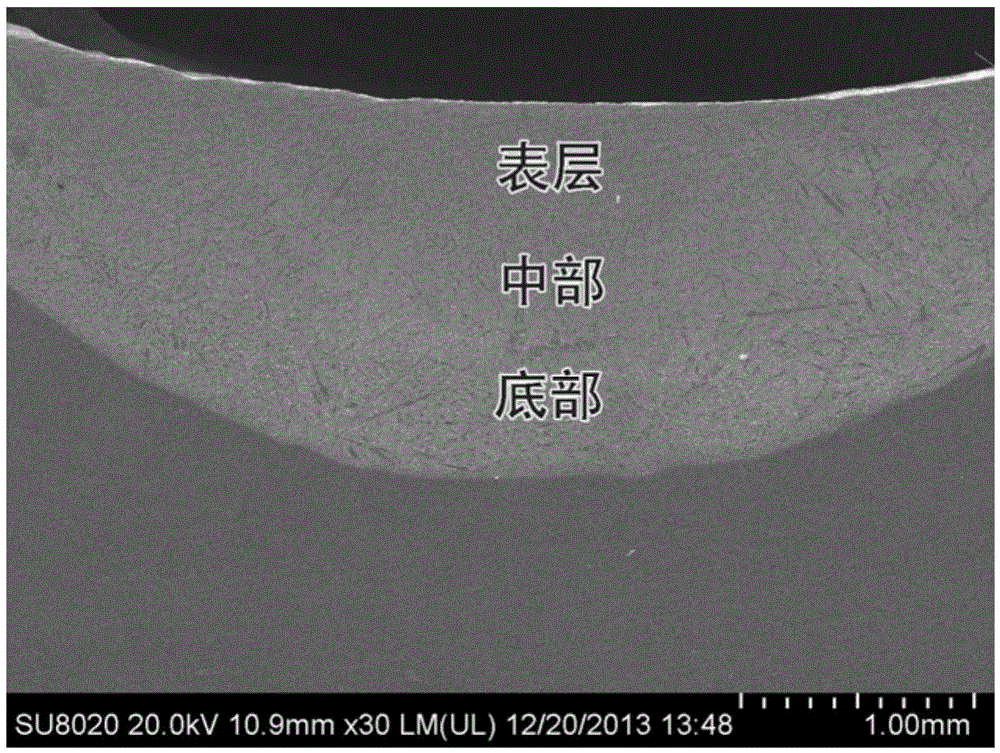

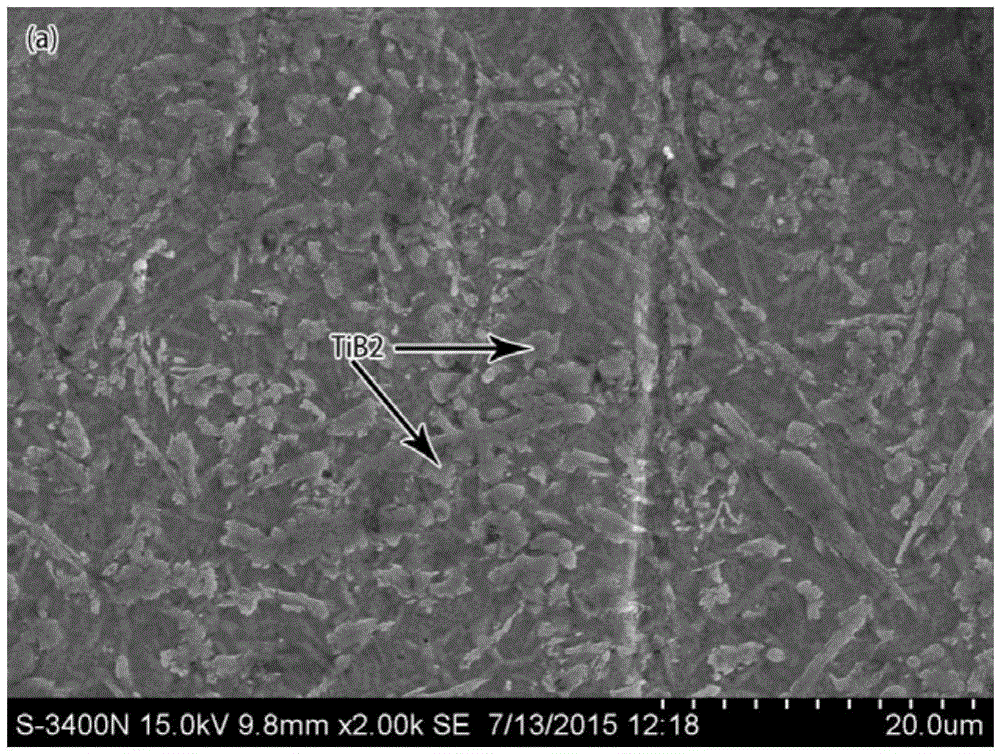

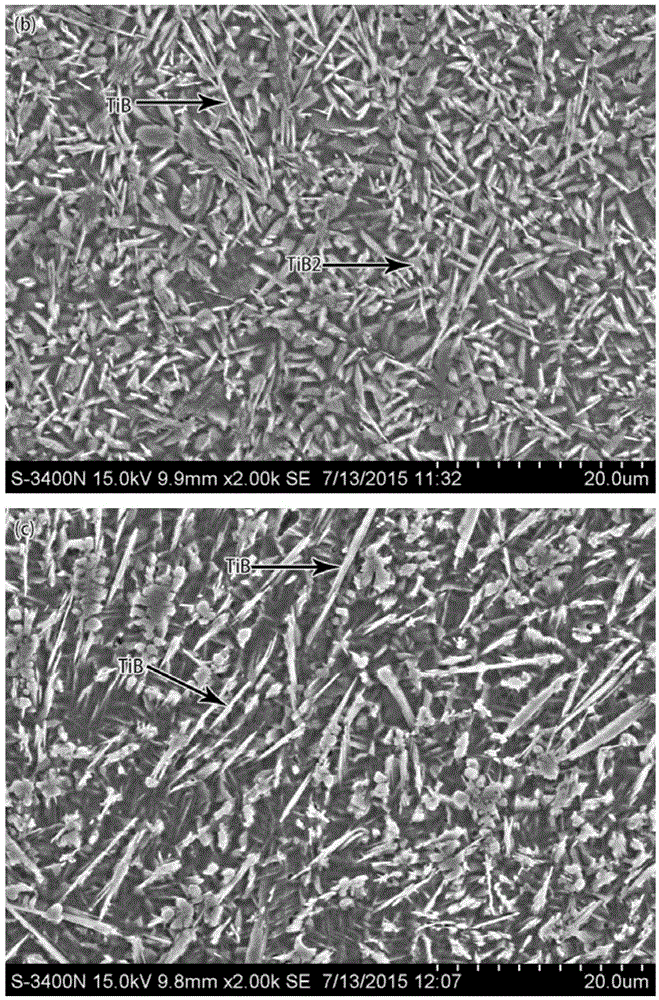

[0026] Polish the surface of Ti-6Al-4V alloy with sandpaper, derust and degrease to obtain a smooth and smooth surface; then TiB 2 Mix mechanically with Ti powder at a mass ratio of 3:2, fully mix with 2123 phenolic resin, and blend into a uniform paste. The phenolic resin is TiB 2 and 2% of the total mass of Ti; Next, the paste is pre-coated on the surface of the Ti-6Al-4V to be processed, the thickness of the pre-layer is 0.5mm, and then placed in a drying oven for 15 hours for later use, and the drying temperature is 150°C .

[0027] Before laser processing, the preset Ti-6Al-4V alloy was preheated to 300°C in a heating furnace, and the temperature was kept stable; finally, the preset layer on the surface of Ti-6Al-4V was processed by IPG fiber laser. The laser process parameters are: laser power 2.4kW, scanning speed 5.5mm / s; spot diameter 5×5mm; argon gas flow rate 15L / min.

Embodiment 2

[0029] Polish the surface of Ti-6Al-4V alloy with sandpaper, derust and degrease to obtain a smooth and smooth surface; then TiB 2 Mix mechanically with Ti powder at a mass ratio of 3:2, fully mix with 2123 phenolic resin, and blend into a uniform paste. The phenolic resin is TiB 2 and 3% of the total mass of Ti; Next, the paste is pre-coated on the surface of the Ti-6Al-4V to be processed, the thickness of the pre-set layer is 0.6mm, and then placed in a drying oven for 20 hours for later use, and the drying temperature is 100°C .

[0030] Before laser processing, the preset Ti-6Al-4V alloy was preheated to 350°C in a heating furnace, and the temperature was kept stable; finally, an IPG fiber laser was used to process the preset layer on the surface of Ti-6Al-4V. The laser process parameters are: laser power 2.6kW, scanning speed 6.5mm / s; spot diameter 5×5mm; argon gas flow rate 10L / min.

Embodiment 3

[0032] Polish the surface of Ti-6Al-4V alloy with sandpaper, derust and degrease to obtain a smooth and smooth surface; then TiB 2 Mix mechanically with Ti powder at a mass ratio of 3:2, fully mix with 2123 phenolic resin, and blend into a uniform paste. The phenolic resin is TiB 2 and 2.5% of the total mass of Ti; next, the paste is pre-coated on the surface of Ti-6Al-4V to be processed, the thickness of the pre-set layer is 0.55mm, and then placed in a drying oven for 28 hours for later use, and the drying temperature is 125°C .

[0033] Before laser processing, the preset Ti-6Al-4V alloy was preheated to 325°C in a heating furnace, and the temperature was kept stable; finally, the Ti-6Al-4V surface preset layer was processed by an IPG fiber laser. The laser process parameters are: laser power 2.5kW, scanning speed 6mm / s; spot diameter 5×5mm; argon gas flow rate 13L / min.

[0034] Table 1: Indentation crack length of the composite coating after Example 1 under the action of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com