Preparation method for instant green soya bean can

A technology for green beans and canned food is applied in the field of preparation of ready-to-eat canned green beans, which can solve the problems of impermanence, damage and loss of nutrients, and difficulty in preservation, and achieve the effects of preventing aging and lowering cholesterol.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

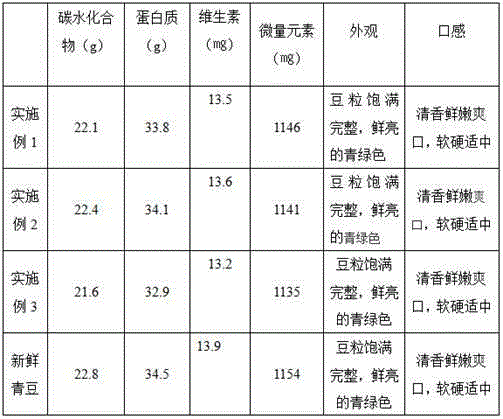

Examples

Embodiment 1

[0022] A preparation method of instant canned green beans, comprising the following steps:

[0023] 1) Select fresh green beans with uniform particles, bright color and plumpness, immerse them in water, the weight ratio of green beans to water is 1:1.8, then add 4% of the mass of green beans with mixed enzyme, mix well, soak at 40°C for 4 days, Take it out, wash it with clean water, and dry it in the air; the mixed enzyme is neutral cellulase, hemicellulase, pectinase and amylase with a mass ratio of 3:3:1.5:1;

[0024] 2) Immerse the green beans treated in step 1) in water again, the weight ratio of green beans to water is 1:1.2, add alkaline protease with 2.8% of the mass of green beans, heat up to 50°C for 9 hours, continue to heat up to 100°C for 7 minutes, Then cool down to 30°C, add lipase with 0.8% of the mass of green beans, keep warm for 1.5h, heat up again to 100°C and keep warm for 6min, take it out, wash with clean water, and dry in the air;

[0025] 3) Spray rice...

Embodiment 2

[0029] A preparation method of instant canned green beans, comprising the following steps:

[0030] 1) Select fresh green beans with uniform particles, bright color and plumpness, immerse in water, the weight ratio of green beans to water is 1:1.5, then add 3% of the mass of green beans to obtain a mixed enzyme, mix well, soak at 38°C for 3 days, Take it out, wash it with clean water, and dry it in the air; the mixed enzyme is neutral cellulase, hemicellulase, pectinase and amylase with a mass ratio of 3:3:1.5:1;

[0031] 2) Immerse the green beans treated in step 1) in water again, the weight ratio of green beans to water is 1:1, add alkaline protease with 2.5% of the mass of green beans, raise the temperature to 50°C and keep it for 8 hours, continue to heat up to 100°C and keep it for 5 minutes, Then cool down to 30°C, add 0.5% lipase of green bean mass, keep warm for 1h, heat up again to 100°C and keep warm for 5min, take it out, wash with clear water, and dry in the air; ...

Embodiment 3

[0036] A preparation method of instant canned green beans, comprising the following steps:

[0037] 1) Select fresh green beans with uniform particles, bright color and plumpness, immerse in water, the weight ratio of green beans to water is 1:2, then add mixed enzyme with 5% of the mass of green beans, mix well, soak at 46°C for 5 days, Take it out, wash it with clean water, and dry it in the air; the mixed enzyme is neutral cellulase, hemicellulase, pectinase and amylase with a mass ratio of 3:3:1.5:1;

[0038] 2) Immerse the green beans treated in step 1) in water again, the weight ratio of green beans to water is 1:1.5, add alkaline protease with 3% of the mass of green beans, heat up to 55°C for 10h, continue to heat up to 105°C for 8min, Then cool down to 30°C, add lipase with 1% of the mass of green beans, keep warm for 2h, heat up again to 105°C and keep warm for 8min, take it out, wash with clear water, and dry in the air;

[0039] 3) Spray rice vinegar on the green ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com