A bionic gravity type high-efficiency and environment-friendly sludge dryer and its realization method

An environmentally friendly and gravity-based technology, applied in chemical instruments and methods, separation methods, fixed filter element filters, etc., can solve the problems of complex structure, large area and labor intensity of belt filter presses. To achieve the effect of flexible and changeable module operation mode, small equipment footprint, and stable processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

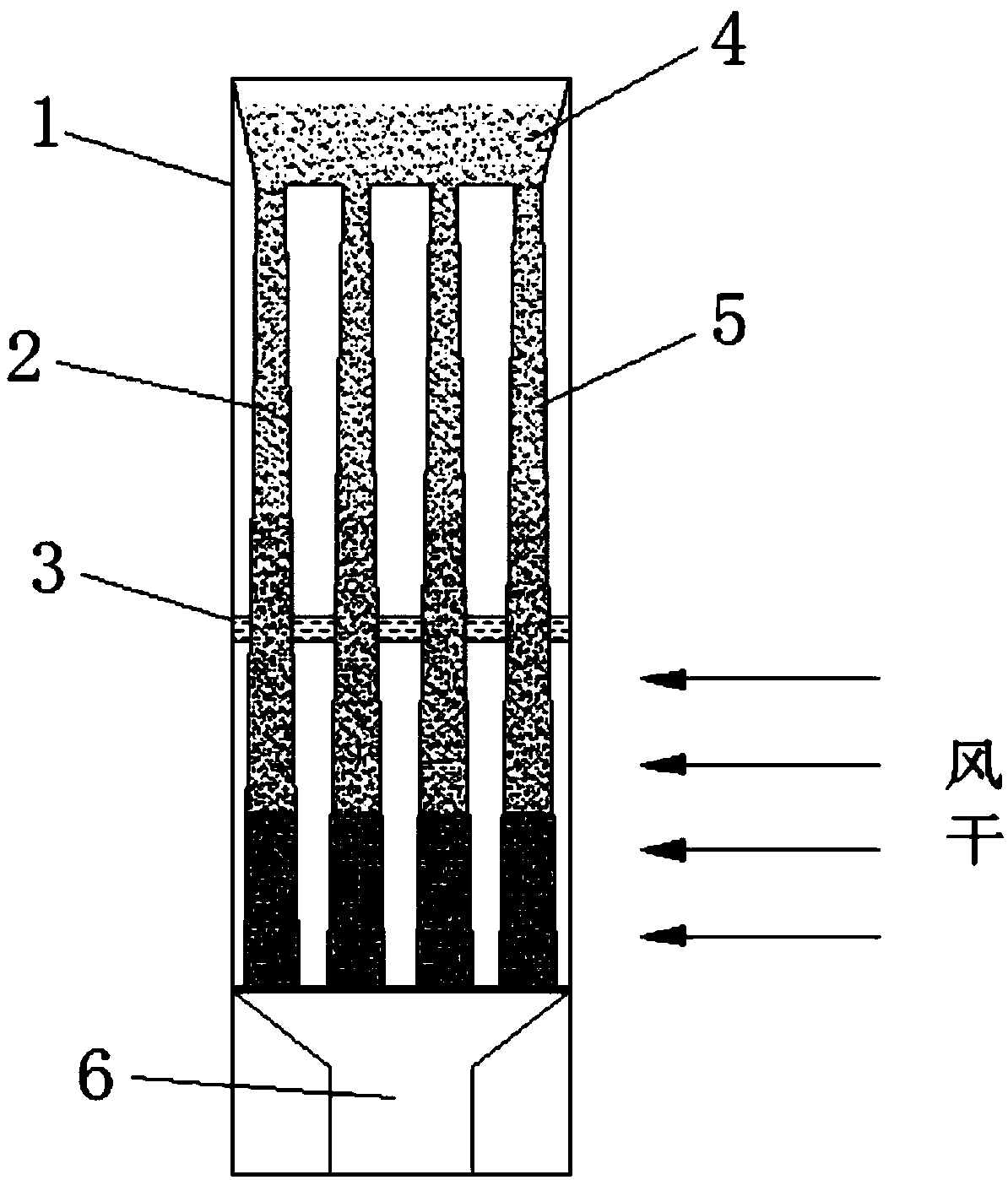

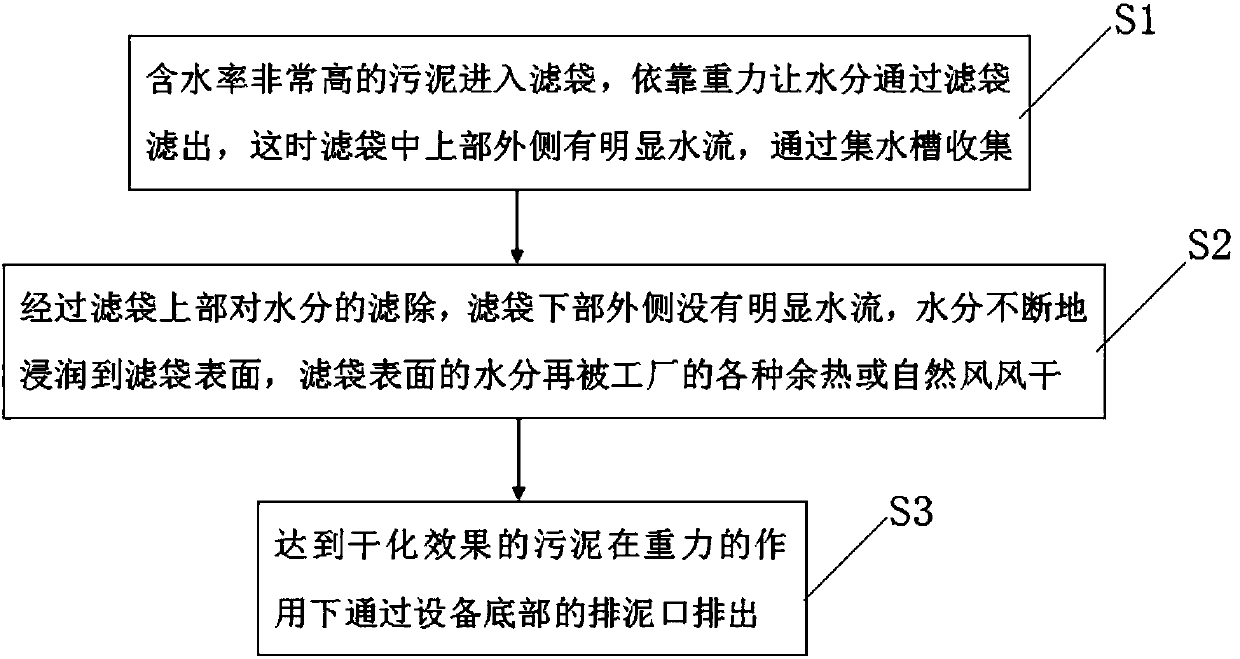

[0029] Such as figure 1 As shown, a bionic gravity type high-efficiency and environment-friendly sludge dryer is characterized in that: it includes a casing 1 and a mud inlet 4 arranged on the top of the casing 1, and a plurality of filters arranged inside the casing 1 for loading sludge bag 5, the mud inlet 4 is in communication with a plurality of filter bags 5 in its lower part, the upper part of the plurality of filter bags 5 is provided with a sump 3, and the bottom of the plurality of filter bags 5 is provided with a mud discharge outlet 6, the The mud discharge port 6 is funnel-shaped.

[0030] In this embodiment, the sides of the plurality of filter bags 5 are all provided with capillary through holes for water to flow through.

[0031] In this embodiment, the plurality of filter bags 5 are tube or sheet structures with a small upper opening and a larger lower opening. This is conducive to the flow of sludge in the filter bag (pipe), and also greatly increases the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com