Graphene oxide/Pebax hollow fiber membrane and preparation method thereof

A technology of fiber membrane and graphene, which is applied in chemical instruments and methods, separation methods, membranes, etc., can solve the problems of poor repeatability and low gas flux, and achieve the goal of maintaining separation factor, improving gas permeation flux, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

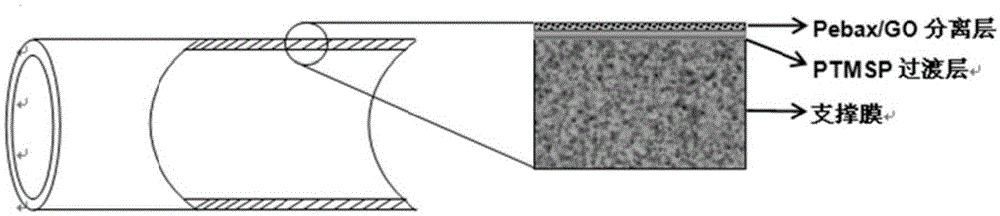

[0035] Transition layer casting solution A formula: PTMSP (polytrimethylsilyl-1-propyne) 3wt%, solvent is n-hexane;

[0036] Separation layer casting solution B formula: Pebax-1657 (block polyetheramide resin) 3wt%, solvent is ethanol / water mixture (mass ratio: 7:3).

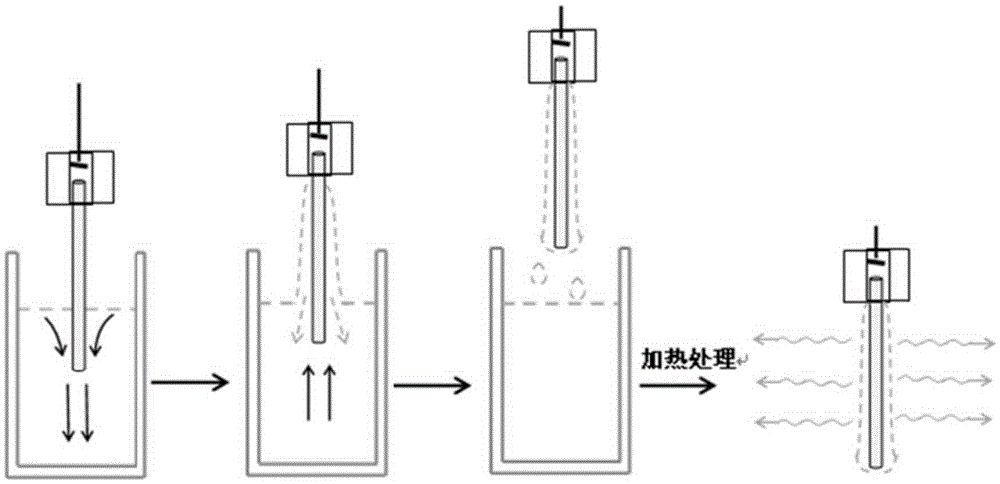

[0037] The preparation method of graphene oxide / Pebax hollow fiber membrane is as follows:

[0038]A commercially available hollow fiber membrane made of PVDF was immersed in deionized water for 24 hours, and then wiped with absorbent paper to remove surface moisture.

[0039] Dissolve PTMSP in n-hexane, and stir it on an electromagnetic stirrer for 2 hours to form a uniform casting solution A, and then use a coating machine to coat the hollow fiber membrane. The operating parameters of the coating machine are set as follows: the descending speed is 0.8cm / s, the residence time is 60s, and the ascending speed is 0.3cm / s. One end of the fixed hollow fiber membrane first enters the casting solution, and when the ...

Embodiment 2

[0044] Transition layer casting solution A formula: PTMSP (polytrimethylsilyl-1-propyne) 3%, solvent is n-hexane;

[0045] Separation layer casting solution B formula: Pebax-1657 (block polyether amide resin) 3%, GO (graphene oxide) 0.1%, solvent is ethanol / water mixture (mass ratio 7:3).

[0046] Immerse the hollow fiber membrane made of PVDF in deionized water for 18 hours, take it out and wipe it with absorbent paper to remove the surface moisture.

[0047] Dissolve PTMSP in n-hexane, and stir it on an electromagnetic stirrer for 2 hours to form a uniform casting solution A, and then use a coating machine to coat the hollow fiber membrane. Set the operating parameters of the coating machine: the descending speed is 0.8cm / s, the residence time is 90s, and the ascending speed is 0.3cm / s. One end of the fixed hollow fiber membrane enters the casting solution first, and when the first coating is completed, it is placed in a 50°C drying oven for 24 hours, and then the other end...

Embodiment 3

[0051] Transition layer casting solution A formula: PTMSP (polytrimethylsilyl-1-propyne) 3%, solvent is n-hexane;

[0052] Separation layer casting solution B formula: Pebax-1657 (block polyether amide resin) 3%, GO (graphene oxide) 0.2%, solvent is ethanol / water mixture (mass ratio 7:3).

[0053] Immerse the hollow fiber membrane made of PVDF in deionized water for 16 hours, take it out and wipe it with absorbent paper to remove the surface moisture.

[0054] Dissolve PTMSP in n-hexane and stir it on an electromagnetic stirrer for 1 hour to form a uniform casting liquid A, and then use a coating machine to coat the hollow fiber membrane. Set the operating parameters of the coating machine: the descending speed is 0.8cm / s, the residence time is 60s, and the ascending speed is 0.3cm / s. One end of the fixed hollow fiber membrane enters the casting solution first, and when the first coating is completed, it is placed in a 55°C drying oven for 24 hours, and then the other end ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com