Bactericide for treating papermaking wastewater and preparation method thereof

A technology of papermaking wastewater and bactericide, which is applied in the field of water treatment, can solve the problems that other harmful substances cannot be treated as a whole, and the bactericidal effect is general, and achieve the effect of reducing content, good effect, and high bactericidal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

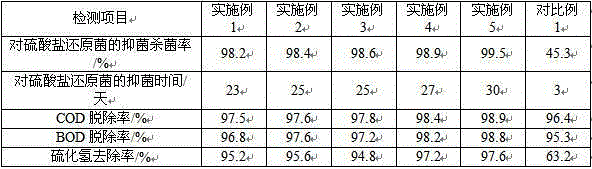

Examples

Embodiment 1

[0018] A bactericide for treating papermaking wastewater, containing the following components in parts by mass: 5 parts of dichlorovinyl salicylamide, 30 parts of ethyl cellosolve, 32 parts of isophorone, 5 parts of tributyltin oxide, 1 part of alkyl benzene sulfonic acid, 1 part of ethyl allicin, 0.5 part of methylene dithiocyanate, 1 part of coral sand, 0.3 part of cuprous oxide, 1 part of calcium hydroxide, ethylene thiuram monosulfide 1 part of mol, 0.4 part of ferrous sulfate.

[0019] A preparation method of a bactericide for treating papermaking wastewater. The steps of the preparation method are as follows:

[0020] Step 1: Combine dichlorovinyl salicylamide, ethyl cellosolve, isophorone, tributyl tin oxide, alkylbenzene sulfonic acid, ethyl allicin, methylene dithiocyanate, Coral sand, cuprous oxide, calcium hydroxide, ethylene thiuram monosulfide, and ferrous sulfate are added to the reaction kettle, and the stirring is started at 100r / min;

[0021] The second step: Raise...

Embodiment 2

[0024] A bactericide for treating papermaking wastewater, containing the following components in parts by mass: 15 parts of dichlorovinyl salicylamide, 50 parts of ethyl cellosolve, 45 parts of isophorone, 15 parts of tributyltin oxide, Alkylbenzene sulfonic acid 5 parts, ethyl allicin 4 parts, methylene dithiocyanate 2.5 parts, coral sand 4 parts, cuprous oxide 0.7 parts, calcium hydroxide 4 parts, ethylene thiuram monosulfide 5 parts per gram and 1.2 parts of ferrous sulfate.

[0025] A preparation method of a bactericide for treating papermaking wastewater. The steps of the preparation method are as follows:

[0026] Step 1: Combine dichlorovinyl salicylamide, ethyl cellosolve, isophorone, tributyl tin oxide, alkylbenzene sulfonic acid, ethyl allicin, methylene dithiocyanate, Coral sand, cuprous oxide, calcium hydroxide, ethylene thiuram monosulfide, and ferrous sulfate are added to the reaction kettle, and the stirring is started at a speed of 200r / min;

[0027] Step 2: Raise t...

Embodiment 3

[0030] A bactericide for treating papermaking wastewater, containing the following components in parts by mass: 13 parts of dichlorovinyl salicylamide, 45 parts of ethyl cellosolve, 42 parts of isophorone, 13 parts of tributyltin oxide, 4 parts of alkyl benzene sulfonic acid, 3 parts of ethyl allicin, 2 parts of methylene dithiocyanate, 3.5 parts of coral sand, 0.6 part of cuprous oxide, 3 parts of calcium hydroxide, ethylene thiuram monosulfide 1 part of ferrous sulfate.

[0031] A preparation method of a bactericide for treating papermaking wastewater. The steps of the preparation method are as follows:

[0032] Step 1: Combine dichlorovinyl salicylamide, ethyl cellosolve, isophorone, tributyl tin oxide, alkylbenzene sulfonic acid, ethyl allicin, methylene dithiocyanate, Coral sand, cuprous oxide, calcium hydroxide, ethylene thiuram monosulfide, and ferrous sulfate are added to the reactor, and the stirring is started at a speed of 150r / min;

[0033] Step 2: Raise the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com