A method for preparing high-purity industrial-grade crystalline salt by utilizing coal chemical concentrated brine

A technology of concentrated brine and coal chemical industry, applied in chemical instruments and methods, special compound water treatment, oxidized water/sewage treatment, etc., can solve the problems of low purity of industrial salt, membrane pollution, etc. The effect of purity and excellent influent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

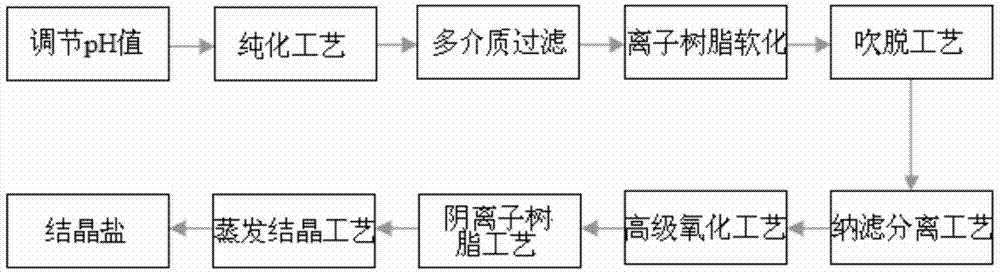

Image

Examples

specific Embodiment approach 1

[0025] Specific implementation mode one: a kind of method of utilizing the concentrated brine of coal chemical industry to prepare high-purity industrial-grade crystalline salt according to the present embodiment is carried out according to the following steps:

[0026] 1. Adjusting the pH value of the adjustment tank: the raw water of the concentrated brine of the coal chemical industry is passed into the adjustment tank, and NaOH is added to the adjustment tank to make the pH value of the outlet water of the adjustment tank be 9-10, and the pH value adjustment is completed, and the coal with a pH value of 9-10 is obtained Chemical brine;

[0027] 2. Purification process: add calcium oxide, magnesium, sodium carbonate, coagulant and coagulant to the coal chemical brine obtained in step 1 with a pH value of 9 to 10 to remove heavy metals and silicon in the coal chemical brine Until the hardness of the effluent is less than 50mg / L, the silicon concentration of the effluent is l...

specific Embodiment approach 2

[0049] Embodiment 2: This embodiment differs from Embodiment 1 in that the coagulant described in step 2 is polyferric chloride. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0050] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the coagulation aid described in step 2 is polyacrylamide. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com