One-component moisture curing-type polyurethane plastic racetrack material and preparation method thereof

A moisture-curing, plastic runway technology, which is applied in the field of light-weight ground decoration materials, can solve the problems of unsafe and environmentally friendly plastic runway materials, and achieve the effects of excellent water resistance and heat air aging resistance, simple operation and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

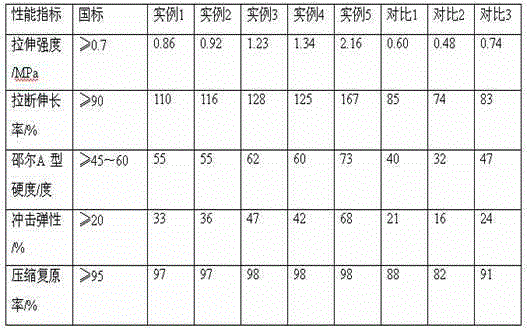

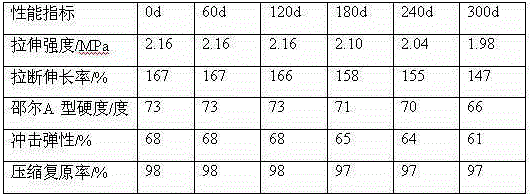

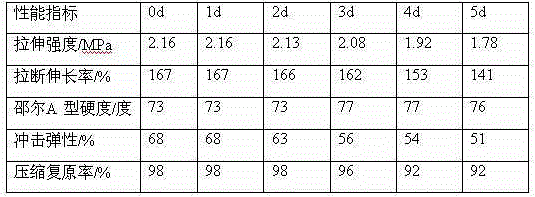

Examples

Embodiment 1

[0024] A one-component moisture-curing polyurethane plastic runway material, consisting of the following raw materials in parts by mass: 30 parts of diphenylmethane diisocyanate, 3 parts of 4,4'-dicyclohexylmethane diisocyanate, polyether triol 25 parts, 10 parts of hydroxyethyl dodecyl alcohol, 4 parts of dibutyl benzoate, 3 parts of dibutyltin dilaurate, 2.5 parts of caprolactam, 1.6 parts of triethanolamine oleate, 2.8 parts of polyethylene wax, disulfide 1.6 parts of dilauryl propionate, 4.5 parts of trimethylolpropane, 20 parts of ethyl acetate, 4 parts of amino silicone oil, 4 parts of filler zinc oxide, 2.5 parts of anti-aging agent A, 3.0 parts of accelerator DM.

[0025] The preparation method comprises the steps of:

[0026] 1) Add polyether polyol, hydroxyethyl dodecyl alcohol and triethanolamine oleate into the reactor, stir, heat up to 105°C, and vacuum dehydrate until the water mass fraction is less than 1*10 -3 , cooled to 50°C for later use;

[0027] 2) Add d...

Embodiment 2

[0030] A one-component moisture-curing polyurethane plastic runway material, consisting of the following raw materials in parts by mass: 15 parts of diphenylmethane diisocyanate, 1 part of 4,4'-dicyclohexylmethane diisocyanate, polyether triol 15 parts, 5 parts of hydroxyethyl dodecyl alcohol, 2 parts of dibutyl benzoate, 1 part of dibutyltin dilaurate, 1 part of caprolactam, 0.8 parts of triethanolamine oleate, 1.5 parts of polyethylene wax, disulfide 0.5 parts of dilauryl propionate, 1.5 parts of trimethylolpropane, 10 parts of ethyl acetate, 2 parts of amino silicone oil, 1 part of filler zinc oxide, 0.5 parts of anti-aging agent A, 1.5 parts of accelerator M.

[0031] The preparation method comprises the steps of:

[0032] 1) Add polyether polyol, hydroxyethyl dodecyl alcohol and triethanolamine oleate into the reactor, stir, heat up to 105°C, and vacuum dehydrate until the water mass fraction is less than 1*10 -3 , cooled to 50°C for later use;

[0033] 2) Add diphenylm...

Embodiment 3

[0036]A one-component moisture-curing polyurethane plastic runway material, consisting of the following raw materials in parts by mass: 25 parts of diphenylmethane diisocyanate, 2.3 parts of 4,4'-dicyclohexylmethane diisocyanate, polyether triol 22 parts, 8 parts of hydroxyethyl dodecyl alcohol, 3.6 parts of dibutyl benzoate, 2.5 parts of dibutyltin dilaurate, 2.2 parts of caprolactam, 1.4 parts of triethanolamine oleate, 2.4 parts of polyethylene wax, disulfide 1.4 parts of dilauryl propionate, 3.5 parts of trimethylolpropane, 16 parts of ethyl acetate, 3.3 parts of amino silicone oil, 3.2 parts of filler zinc oxide, 1.8 parts of antioxidant A, and 2.6 parts of accelerator M.

[0037] The preparation method comprises the steps of:

[0038] 1) Add polyether polyol, hydroxyethyl dodecyl alcohol and triethanolamine oleate into the reactor, stir, heat up to 105°C, and vacuum dehydrate until the water mass fraction is less than 1*10 -3 , cooled to 50°C for later use;

[0039] 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com