Isomerization method for n-butene

A technology for isomerization and n-butene, which is used in isomerization to produce hydrocarbons, chemical instruments and methods, and organic chemistry. isomerization and other problems, to achieve the effect of improving conversion rate, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

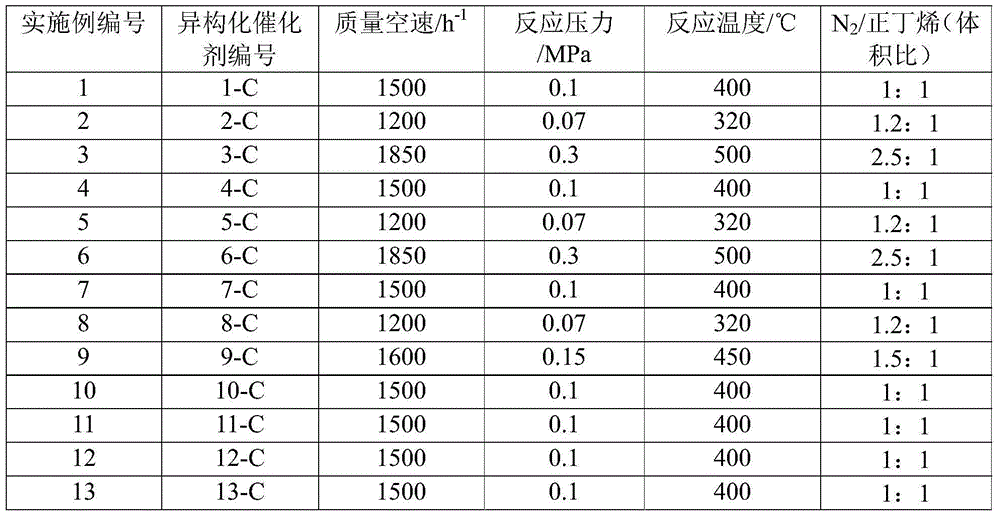

Examples

preparation example 1

[0060] This preparation example is used to prepare the isomerization catalyst described in the present invention.

[0061] Step 1: obtain modified ferrierite.

[0062] Modification treatment: Take 90g of sodium ferrierite ZSM-23 (purchased from Shanghai Shentan Environmental Protection New Material Co., Ltd., the same below), and add it to 1000mL of a solution containing 32g of ammonium nitrate and 35.4g of ammonium fluorosilicate. Contact treatment at ℃ for 8h, then cooling, filtering, drying at 100℃ for 10h, and calcining at 500℃ for 4h to obtain modified ferrierite 1-A.

[0063] The second step: obtaining the isomerization catalyst composition.

[0064] A mixed solution of 100 g of modified Ferrierite 1-A, 50 g of alumina, 5 g of turnip powder, 8 g of nitric acid and 100 g of water was added into a kneader and stirred until the materials were evenly mixed. The isomerization catalyst composition 1-B was obtained.

[0065] The third step: preparing the isomerization cataly...

preparation example 2

[0068] This preparation example is used to prepare the isomerization catalyst described in the present invention.

[0069] Step 1: obtain modified ferrierite.

[0070] Modification treatment: Take 90g of sodium ferrierite ZSM-35 (purchased from Dalian Ketelli Chemical Co., Ltd., the same below), add it to 1000mL solution containing 55.4g ammonium nitrate and 72g ammonium fluorosilicate, at 95°C After contacting for 7 hours, cooling, filtering, drying at 120°C for 8 hours, and calcining at 400°C for 6 hours, the modified ferrierite 2-A was obtained.

[0071] The second step: obtaining the isomerization catalyst composition.

[0072] A mixed solution of 100 g of modified ferrierite 2-A, 20 g of silicon oxide, 10 g of methylcellulose, 4 g of nitric acid and 100 g of water was added into a kneader and stirred until the materials were mixed evenly. The isomerization catalyst composition 2-B was obtained.

[0073] The third step: preparing the isomerization catalyst.

[0074] Th...

preparation example 3

[0076] This preparation example is used to prepare the isomerization catalyst described in the present invention.

[0077] Step 1: obtain modified ferrierite.

[0078] Modification treatment: Take 90g of sodium ferrierite ZSM-38 (purchased from Shanghai Shentan Environmental Protection New Material Co., Ltd., the same below), and add it to 1000mL of a solution containing 9.4g of ammonium nitrate and 7.6g of ammonium fluorosilicate. Contact treatment at 75°C for 10 hours, cooling, filtration, drying at 90°C for 12 hours, and calcination at 600°C for 3 hours to obtain modified ferrierite 3-A.

[0079] The second step: obtaining the isomerization catalyst composition.

[0080] A mixed solution of 100 g of modified Ferrierite 3-A, 80 g of alumina, 1 g of turnip powder, 15 g of nitric acid and 100 g of water was added into a kneader and stirred until the materials were evenly mixed. The isomerization catalyst composition 3-B was obtained.

[0081] The third step: preparing the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com