A kind of high strength polysulfone resin and preparation method thereof

A polysulfone resin, high-strength technology, applied in the field of high-strength polysulfone resin and its preparation, can solve the problems of polyethersulfone with deep color, low light transmittance, poor flexibility, etc., achieve good thermal stability, reduce process , the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Follow the steps below to prepare high-strength polysulfone resin:

[0029] 1. Salt formation reaction: In a 300-liter stainless steel reaction kettle filled with nitrogen protection, equipped with a nitrogen pipe, a condensation water separator, and a high-efficiency stirrer, first add 75.0kg of N-methylpyrrolidone, start stirring and raise the temperature to 80°C. Add 35.0kg (122mmol) 4,4'-dichlorodiphenyl sulfone and 29.47kg (129mmol) bisphenol A in sequence. After the monomers are completely dissolved, add 15.28kg (144mmol) sodium carbonate to the system, and then add 60.0L For o-trimethylbenzene, continue to stir and heat up to 170°C, and perform a salt-forming reaction for 1 hour, and the solid content of the system in the salt-forming reaction stage is 25%;

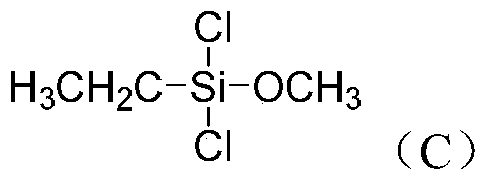

[0030] 2. Polymerization reaction: After the salt formation is completed, all the o-trimethylbenzene is evaporated, and then the temperature is raised to 200°C, stirred at a speed of 50-70 rpm, kept at a con...

Embodiment 2

[0033] Follow the steps below to prepare high-strength polysulfone resin:

[0034] 1. Salt formation reaction: In a 300-liter stainless steel reaction kettle filled with nitrogen protection, equipped with a nitrogen pipe, a condensation water separator, and a high-efficiency stirrer, first add N-methylpyrrolidone, start stirring and heat up to 60°C, and then add 100mmol of 4,4'-dichlorodiphenyl sulfone, 106mmol of bisphenol A, after the monomers are completely dissolved, add 111mmol of sodium carbonate to the system, then add 60.0L of mesitylene, continue to stir and heat up to 190°C for salt formation reaction 2h, the solid content of the system in the salt-forming reaction stage is 30%;

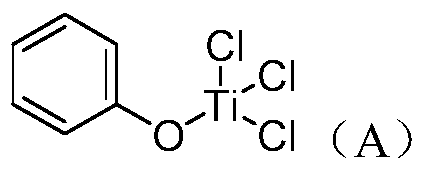

[0035] 2. Polymerization reaction: After the salt formation is completed, all the mesitylene is evaporated, and then the temperature is raised to 230°C, stirred at a speed of 50-70 rpm, kept at a constant temperature for 3 hours, and 790g (3.2mmol) of compound A is added to the system to in...

Embodiment 3

[0039] Follow the steps below to prepare high-strength polysulfone resin:

[0040] 1. Salt formation reaction: In a 300-liter stainless steel reaction kettle filled with nitrogen protection, equipped with a nitrogen pipe, a condensation water separator, and a high-efficiency stirrer, first add N-methylpyrrolidone, start stirring and heat up to 70°C, and then add 106mmol of 4,4'-dichlorodiphenyl sulfone, 100mmol of bisphenol A, after the monomers are completely dissolved, add 120mmol of sodium carbonate to the system, then add 60.0L of m-trimethylbenzene, continue to stir and raise the temperature to 180°C for salt formation reaction 2h, the solid content of the system in the salt-forming reaction stage is 28%;

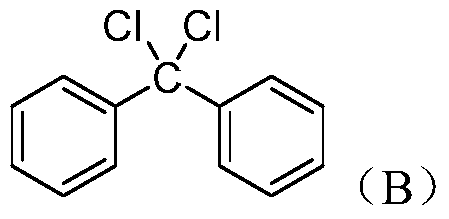

[0041] 2. Polymerization reaction: after the completion of salt formation, steam all m-trimethylbenzene, then raise the temperature to 220°C, stir at a speed of 50-70 rpm, keep the temperature at a constant temperature for 5 hours, add 10.6 mmol of compound B to the sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com