PVC plastic plate special for stone compounding and production method thereof

A plastic board and stone technology, applied in the special PVC plastic board for stone composite and its production field, can solve the problems of high brittleness, unsatisfactory strength and toughness, etc., achieve less agglomeration, improve compatibility, and high flexural strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

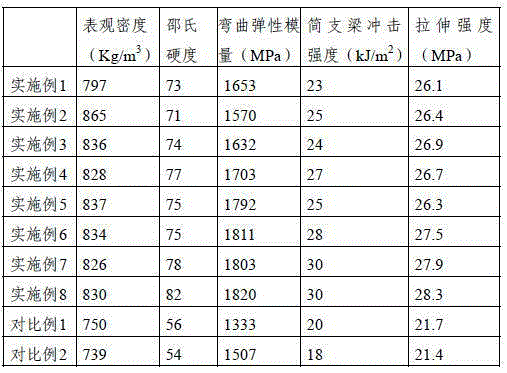

Examples

Embodiment 1

[0028] The composition of the special PVC plastic board for stone composite in Example 1 is: 100 parts of PVC (average degree of polymerization 800), 20 parts of light calcium carbonate, 30 parts of wood flour, 0.001 part of polylactic acid, and the total parts by weight are 24.8 parts of PVC processing aids; PVC processing aids include lubricant (0.3 parts of coalic acid ester, 0.5 parts of stearic acid), impact modifier (3 parts of MBS resin), foaming agent (AC foaming agent 2 parts, 1 part of NC foaming agent), foam regulator (PVC lubricious processing aid LP-21 produced by Shandong Ruifeng Polymer Materials Co., Ltd., the dosage is 15 parts), and lubricious processing aid (Shandong PVC lubricating processing aid LP-102 produced by Ruifeng Polymer Materials Co., Ltd., the dosage is 3 parts).

[0029] Foaming regulator can choose LP foaming regulator produced by Shandong Ruifeng Polymer Materials Co., Ltd. LP-530), you can also choose the PA foaming regulator from Japan Zho...

Embodiment 2

[0039] The composition of the special PVC plastic board for stone composite in Example 2 is: 100 parts of PVC (average degree of polymerization 900), 90 parts of light calcium carbonate, 0.1 part of wood flour, 20 parts of polylactic acid, and the total parts by weight are 27 parts of PVC processing aids; PVC processing aids include lubricants (0.4 parts of PE wax, 0.6 parts of high-density chlorinated polyethylene wax, 1 part of lubricant ZB-60 produced by Zibo Huaxing Auxiliary Co., Ltd.), impact resistance Modifier (2 parts of MBS resin), foaming agent (1 part of AC foaming agent, 2 parts of NC foaming agent), foam regulator (15 parts of LP-23 from Zibo Huaxing Auxiliary Co., Ltd.), also contains Lubricity processing aid (5 parts of PVC lubricity processing aid LP-102 produced by Shandong Ruifeng Polymer Materials Co., Ltd.) and PVC processing modifier (0.5 parts).

[0040] The production method of embodiment 2 is identical with embodiment 1.

[0041] Lubricants ZB-60 and ...

Embodiment 3

[0045] The composition of the special PVC plastic plate for stone composite in Example 3 is: 100 parts of PVC (average degree of polymerization 900), 55 parts of light calcium carbonate, 15 parts of wood flour, 10 parts of polylactic acid, and the total parts by weight are 39.35 parts of PVC processing aids; PVC processing aids include lubricants (0.6 parts of high-density chlorinated polyethylene wax, 1.4 parts of lubricant ZB-60), impact modifiers (7 parts of MBS resin, 4 parts of ACR resin ), foaming agent (2.5 parts of AC foaming agent, 2.5 parts of NC foaming agent), foaming regulator (17 parts of LP-530 from Zibo Huaxing Auxiliary Co., Ltd.), and lubricious processing aid (0.3 parts PVC lubricating processing aid LP-102 produced by Shandong Ruifeng Polymer Materials Co., Ltd.), PVC processing modifier (0.05 parts of PVC processing modifier ZB-20 produced by Zibo Huaxing Auxiliary Co., Ltd.) and stabilizer (5 parts of calcium zinc composite stabilizer).

[0046] The prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com