Chain oil composition with excellent high temperature abrasion resistance

A high-temperature anti-wear and composition technology, applied in the field of lubricating oil, can solve the problem of less attention to the high-temperature anti-wear performance of high-temperature chain oil, and achieve the effects of excellent high-temperature anti-wear performance, not easy to coking, and excellent high-temperature anti-wear performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

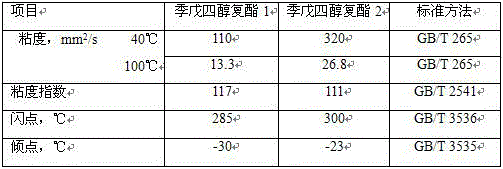

[0019] Add 0.36mol (49g) of pentaerythritol, 0.1075mol (15.7g) of adipic acid, 0.67mol (96.7g) of n-octanoic acid and 0.54mol (85.4g) of isononanoic acid into a 500ml three-neck flask equipped with a condenser tube and a water separator , solid superacid SO 4 2- / ZrO 2 0.196g, petroleum ether (90~120) 20ml, start stirring, raise the temperature to 160°C for reflux reaction for 4h, then raise the temperature to 200°C at a rate of 10°C / h, continue to keep warm for 4h, and the reaction ends. Distill the solvent and excess acid under reduced pressure at 0.95MPa and 200°C to remove the solvent and excess acid, then add 5% activated clay and stir at 100°C for 2h and filter to obtain the final product pentaerythritol complex ester 1.

Embodiment 2

[0021] Add 0.36mol (49g) of pentaerythritol, 0.164mol (24g) of adipic acid, 0.397mol (57.3g) of n-octanoic acid, 0.699mol (110.6g) of isononanoic acid, Solid Superacid SO 4 2- / ZrO 2 0.196g, petroleum ether (90~120) 20ml, start stirring, raise the temperature to 160°C for reflux reaction for 4h, then raise the temperature to 200°C at a rate of 10°C / h, keep it warm for 8h, and the reaction ends. Distill the solvent and excess acid under reduced pressure at 0.95MPa and 200°C to remove the solvent and excess acid, then add 5% activated clay and stir at 100°C for 2h and filter to obtain the final product pentaerythritol complex ester 2.

Embodiment 3

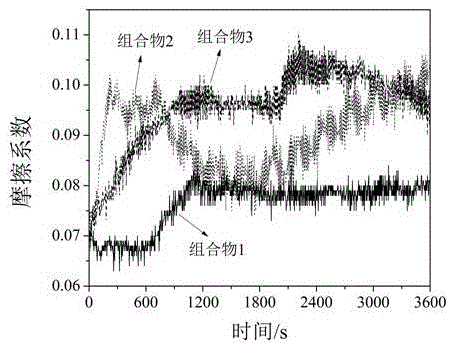

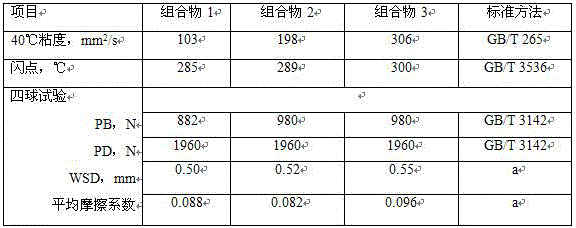

[0023] Take 92g of pentaerythritol complex ester 1 and add it to a 250ml beaker, then add 1.5g of butyl / octyl diphenylamine, 1g of nitrogen phenyl-α-naphthylamine, 0.5g of V9317, 1.5g of trioctyl phosphite, 1g of tricresyl phosphate, 1.5 gN,N-molybdenum di(dodecyl)dithiocarbamate, 0.8g benzotriazole, 0.2g T746, heated to 80°C and stirred for 1h to obtain the final product, which is designated as composition 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com