Taxus chinensis oil and extracting method thereof

An extraction method, the technology of yew oil, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of extracting yew oil from yew seeds that have never been seen, and achieve good temperature resistance and high concentration chunky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Extraction method of yew oil: remove the pulp (aril) from fresh yew seeds and elute to obtain 500g of pure yew seeds, bake, dry, crush into 40-60 mesh, treat with microwave equipment for 1-2min, and then put into In the solvent method extractor, the ratio of raw material to solvent is 1:6, heated at 30-35°C, and the dynamic leaching time is 2-3h. Repeat this method for filtering the solution for 3 times, combine and filter the extraction solution, vacuum distillation and concentration to obtain oil . The vacuum process temperature is controlled within 55°C to extract oil. The solvent is recovered and reused, and the yew crude oil obtained by the solvent method is desolvated, impurity-removed and refined by a supercritical CO? device, with a pressure of 26mpa, a temperature of 42°C, a CO? , finely filtered to obtain 169.5 grams of yellowish and transparent yew oil, with a yield of 33.9%.

[0017] Choose the No. 6 extraction solvent oil that is harmless to human body, h...

experiment example

[0020] Taxus oil chemical composition analysis content weight percent comprises as follows:

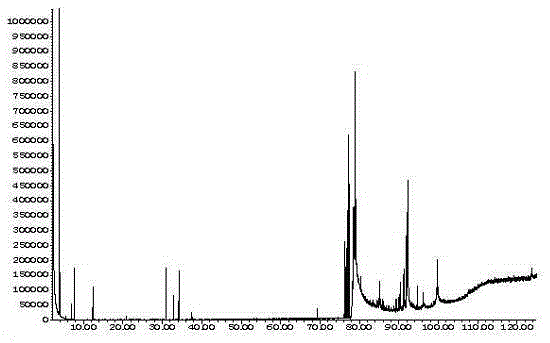

[0021] Operating conditions:

[0022] Column: Quartz capillary column: length 60m, inner diameter about 0.25mm.

[0023] Stationary phase: 100% dimethyl polysiloxane packing.

[0024] Film thickness: 0.25 μm.

[0025] Chromatographic oven temperature: linearly programmed temperature rise from 60°C to 280°C at a rate of 2°C / min, and finally kept at 280°C for 15 minutes.

[0026] Injection port temperature: 280°C.

[0027] Detector: Quadrupole mass spectrometer detector.

[0028] Carrier gas: helium.

[0029] Carrier gas flow rate: 1.5ml / min.

[0030] Injection volume: about 0.2 μl.

[0031] Split ratio: 1 / 100.

[0032] Pentane 1.265 Octane 1.374 trans-2-Heptenal 0.999 Trans-2-Decenal Trans-2-Decenal 1.922 2,4-Nonadienal 2,4-Nonenal 0.962 2,4-Decadienal 2,4-Decadienal 1.993 Methyl 5,9-heptadecadienoate 3.596 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com