Indirect coupling conic fiber grating ultrasonic sensor

An ultrasonic sensor and tapered optical fiber technology, applied in the field of sensors, can solve problems such as non-directional recognition, large capacitance influence, interference, etc., achieve good response characteristics, high spectral signal-to-noise ratio, and facilitate real-time acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

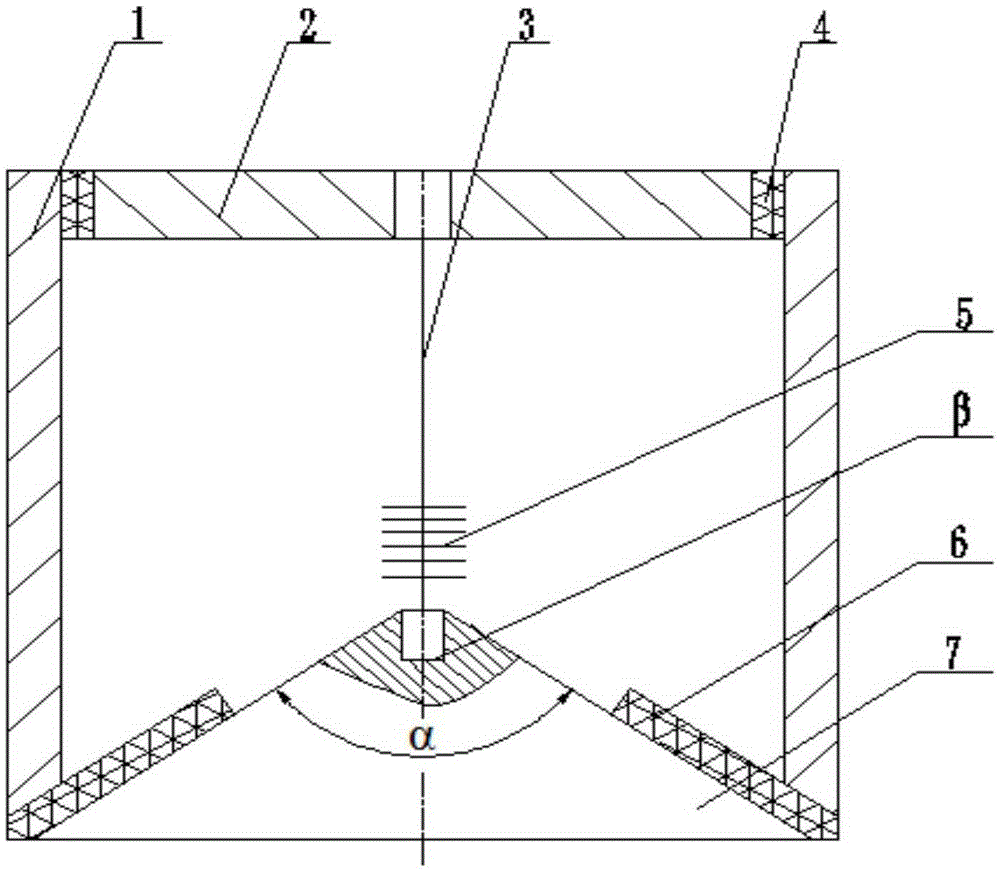

[0016] exist figure 1 Among them, the indirect coupling tapered fiber grating ultrasonic sensor of this embodiment is connected by a housing 1, a cover 2, an optical fiber 3, a cover anechoic pad 4, a grating 5, an acoustic coupling cone anechoic pad 6, and an acoustic coupling cone 7 constitute.

[0017] A cover 2 is bonded to the upper end of the shell 1 with epoxy resin, and a center hole is processed at the center of the cover 2, and a cover is used to silence the sound between the cover 2 and the shell 1. Pad 4, cover The sound-absorbing pad 4 is used to absorb the residual ultrasonic waves in the upper part of the housing 1, and prevent multiple reflections from overlapping to form clutter. The lower end of the housing 1 is bonded with an acoustic coupling cone 7 with epoxy resin, and the acoustic coupling cone muffler pad 6 is bonded between the acoustic coupling cone 7 and the lower end of the housing 1 with epoxy resin, and the acoustic coupling cone muffler pad is ...

Embodiment 2

[0019] In this embodiment, an acoustic coupling cone 7 is bonded to the lower end of the housing 1 with epoxy resin. The diameter of the bottom surface of the acoustic coupling cone 7 is the same as the outer diameter of the housing 1, and the cone angle α of the acoustic coupling cone 7 is 60°. . Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0021] In this embodiment, an acoustic coupling cone 7 is bonded to the lower end of the housing 1 with epoxy resin. The diameter of the bottom surface of the acoustic coupling cone 7 is the same as the outer diameter of the housing 1, and the cone angle α of the acoustic coupling cone 7 is 120°. . Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com