Analysis method of organic additives in rubber and plastic auxiliaries with rubber as carriers

An organic additive and analysis method technology, applied in the rubber and plastic industry, can solve the problems of difficult extraction and discrimination, low content, etc., and achieve the effects of fast and convenient method, high sensitivity and accuracy, and short extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

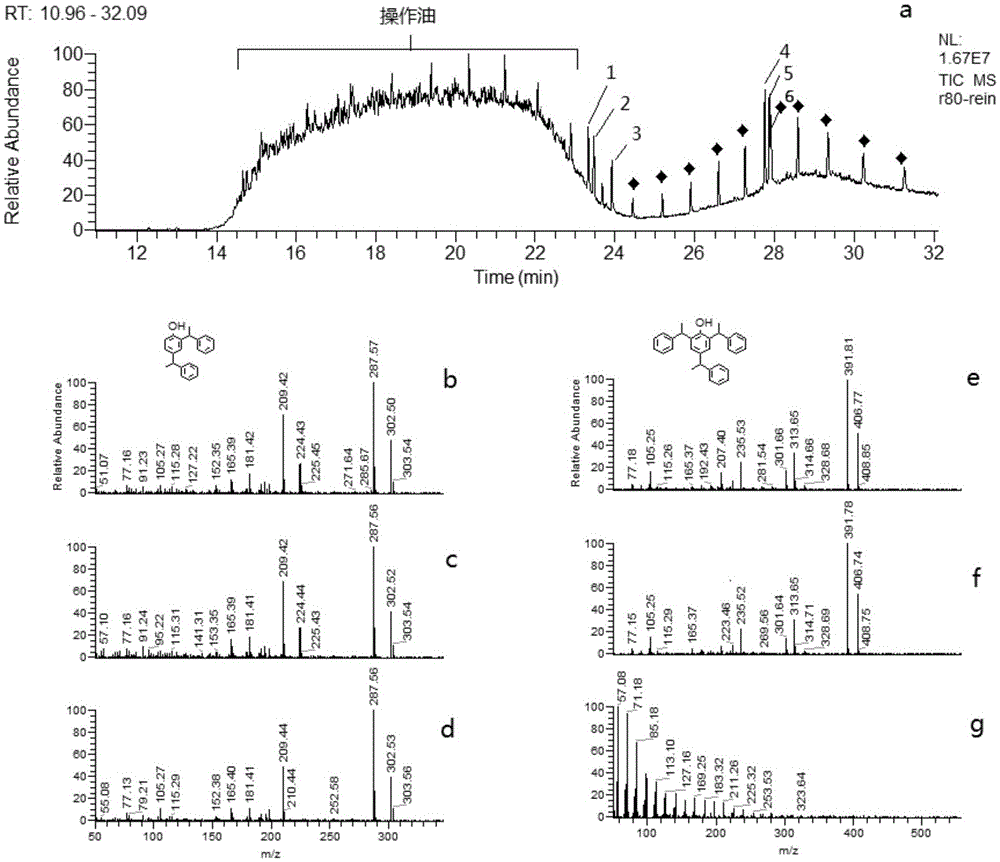

[0025] Example 1: Analysis of organic additives in a certain rubber adhesive resorcinol 80 (R80) (product resorcinol effective content is 80%, rubber carrier content 20%)

[0026] 1.1 Take about 300mg of R80 sample, cut it into pieces, and make it smaller than 5mm 3 For the granules, put the granules in a 50mL pear-shaped bottle, add 10mL of chloroform, ultrasonic at 50°C for 15min, and let stand;

[0027] 1.2 After the sample is completely dissolved, continue to add 20mL of acetone, and conduct ultrasonic extraction at room temperature for 30min, gel blocks appear in the pear-shaped bottle, and phase separation occurs;

[0028] 1.3 Take 1 μL of the extract for detection by gas chromatography-mass spectrometry, where the detection conditions are:

[0029] The chromatographic conditions are: TR-5MS chromatographic column, column length: 30m; inner diameter: 0.25mm; film thickness: 0.25μm. The control program of the column temperature is: the initial temperature is 50°C, keep ...

Embodiment 2

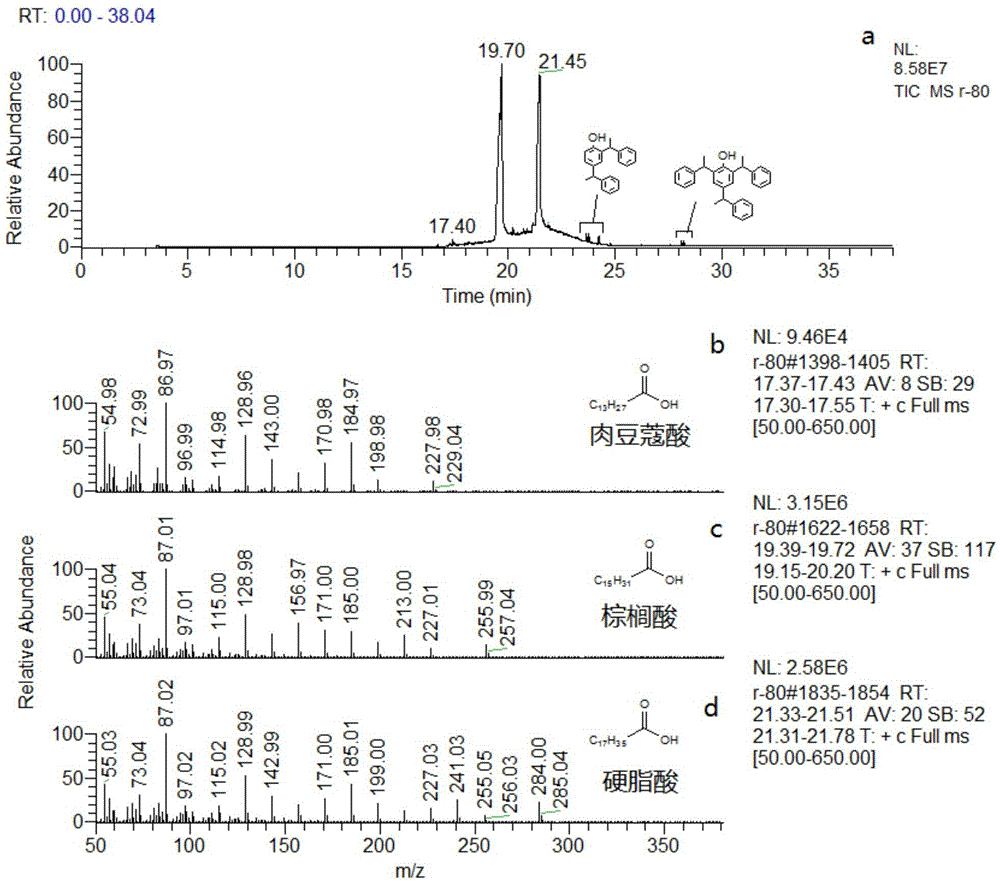

[0033] Example 2: Analysis of organic additives in the rubber adhesive resorcinol 80 (R80) produced by Sanshui Taixin (the effective content of resorcinol in the product is 80%, and the rubber carrier content is 20%)

[0034] 2.1 Take about 500mg of R80 sample and cut it into pieces to make the size less than 5mm 3 granules, put the granules in a 50mL pear-shaped bottle, add 10mL tetrahydrofuran (THF), and let stand after ultrasonication for 20min at room temperature;

[0035]2.2 After the sample is completely dissolved, continue to add 20mL of ethanol, and conduct ultrasonic extraction at room temperature for 30 minutes, gel blocks appear in the pear-shaped bottle, and phase separation occurs;

[0036] 2.3 Take 1 μL of the extract for detection by gas chromatography-mass spectrometry, where the detection conditions are:

[0037] The chromatographic conditions are: HP-5MS chromatographic column, column length: 30m; inner diameter: 0.32mm; film thickness: 0.25μm. The control ...

Embodiment 3

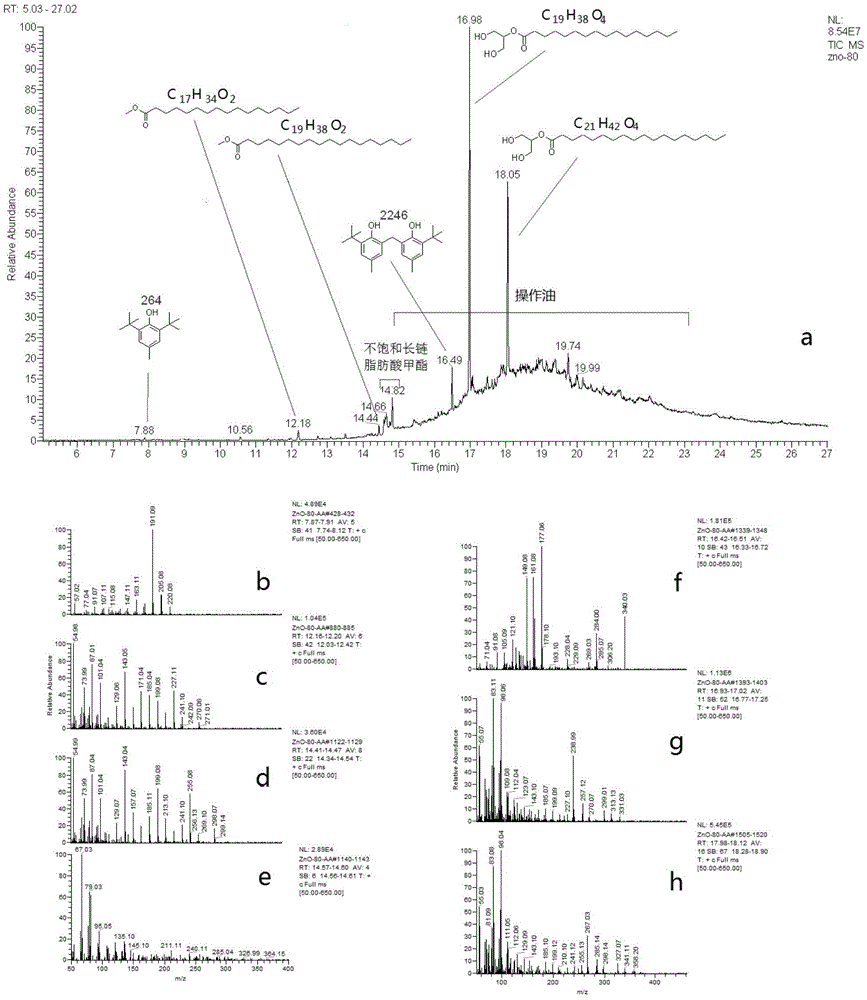

[0041] Example 3: Analysis of organic additives in a zinc oxide 80 (ZnO80) product on the market (the effective content of zinc oxide in the product is 80%, and the rubber carrier content is 20%)

[0042] 3.1 Take 10 columnar Zn80 masterbatches and cut them into pieces to make them smaller than 5mm 3 granules, put the granules in a 100mL pear-shaped bottle, add 20mL tetrahydrofuran (THF), and put them under ultrasonication for 30min at 60°C and let them stand still;

[0043] 3.2 The sample is completely dissolved, and the upper and lower layers are layered. The white powdery insoluble matter in the lower layer is ZnO, and the viscous solution in the upper layer is a mixed solution of masterbatch, organic additives and THF; continue to add 40mL of methanol, ultrasonically extract at room temperature for 30min, and place in a pear-shaped bottle Gel blocks appear and phase separation occurs; at this time, a white ZnO solid in the lower layer appears in the pear-shaped bottle, a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com