Composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane and combined technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem that nanofiltration membranes do not have antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

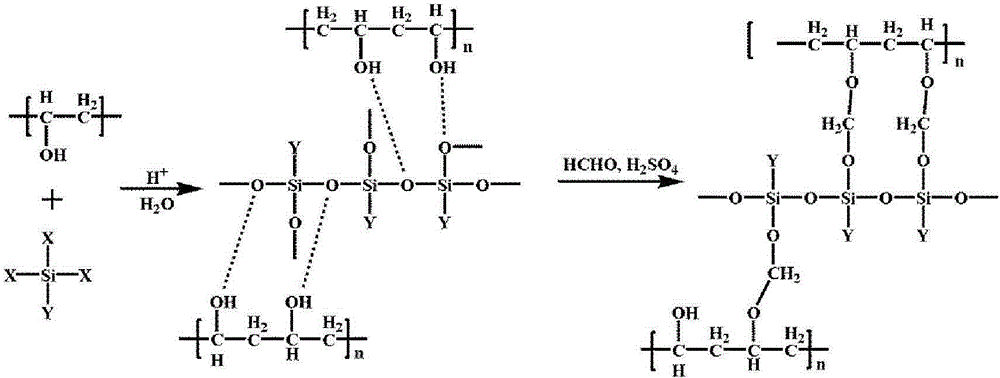

[0031] The present invention also provides a kind of preparation method of composite nanofiltration membrane, and this method comprises the following steps:

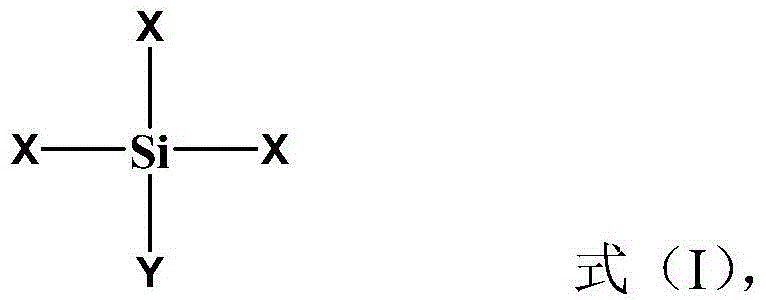

[0032] (1) dissolving a hydroxyl-containing polymer and a silane coupling agent containing a structure shown in formula (I) in a solvent to prepare a coating solution;

[0033] (2) coating the coating solution on the support layer to form an initial film;

[0034] (3) immerse the supporting layer formed with the initial film in step (2) into a solution containing a crosslinking agent and a crosslinking catalyst to carry out a crosslinking reaction to obtain a crosslinked network structure comprising the supporting layer and the surface of the supporting layer Composite nanofiltration membrane;

[0035]

[0036] Among them, Y is a linear or branched alkyl group containing C1-C20, and the end of the linear or branched alkyl group is a quaternary amine group; X is Cl, methoxy (OMe), ethoxy (OEt), OC 2 h 4 OCH 3 , OS...

Embodiment 1

[0064] This embodiment is used to illustrate the composite nanofiltration membrane provided by the present invention and its preparation method.

[0065] Dissolve 1.0g of polyvinyl alcohol (PVA), 0.8g of dimethyloctadecyl [3-(trimethoxysilyl) propyl]ammonium chloride in 100g of deionized water, and then drop into 1mol / L of dilute hydrochloric acid to adjust the pH of the solution to 1. At room temperature, after stirring for 24 hours, filter to obtain a clear coating solution;

[0066] After coating the dilute coating solution evenly on the polysulfone bottom membrane, put it into an oven at 60°C and heat it for 30 minutes to ensure that the solvent is completely evaporated; , 10 g of formaldehyde and 15 g of sodium sulfate, heated at 60° C. for 30 min, took out the composite nanofiltration membrane, washed it with water, and soaked it in deionized water.

[0067] After soaking the obtained composite nanofiltration membrane in water for 24 hours, the water flux and desalina...

Embodiment 2

[0071] This embodiment is used to illustrate the composite nanofiltration membrane provided by the present invention and its preparation method.

[0072] Dissolve 1.0 g of chitosan and 1.0 g of dimethyloctadecyl [3-(trimethoxysilyl) propyl] ammonium chloride in 100 g of deionized water, and then drop into 1 mol / L dilute hydrochloric acid to adjust the pH of the solution to 1. At room temperature, after stirring for 24 hours, filter to obtain a clear coating solution;

[0073] After coating the dilute coating solution evenly on the polysulfone bottom membrane, put it into an oven at 60°C and heat it for 30 minutes to ensure that the solvent is completely evaporated; , 10g of formaldehyde and 15g of sodium sulfate, heated at 50°C for 30min, then took out the composite nanofiltration membrane, washed it with water and soaked it in deionized water.

[0074] After soaking the obtained composite nanofiltration membrane in water for 24 hours, the water flux and desalination rate we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com