Preparation method and application of Co-Mn-MCM-41 molecular sieve

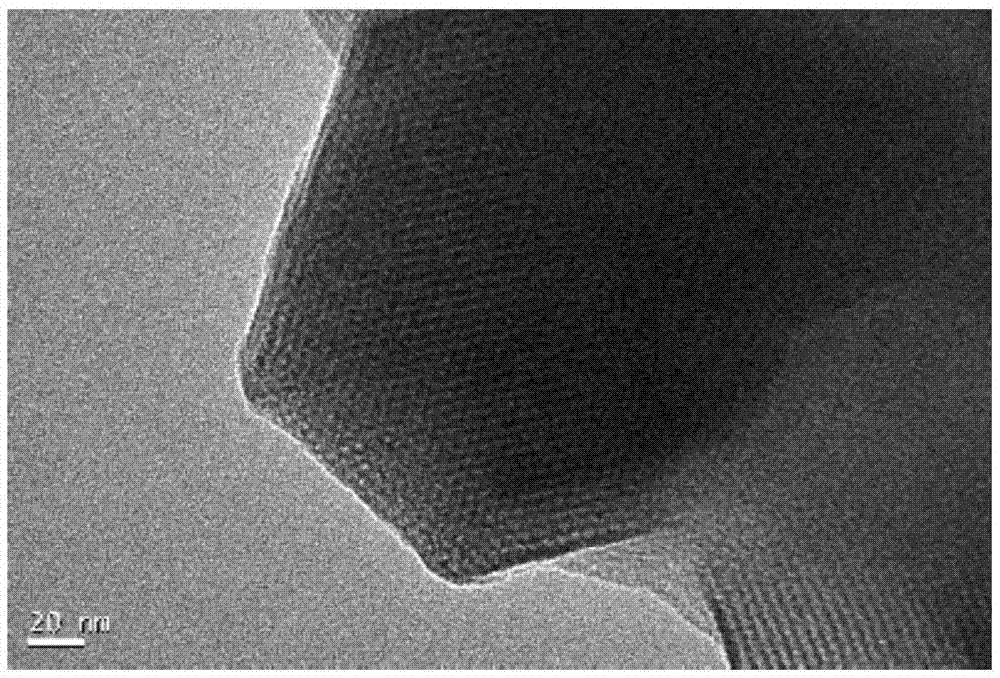

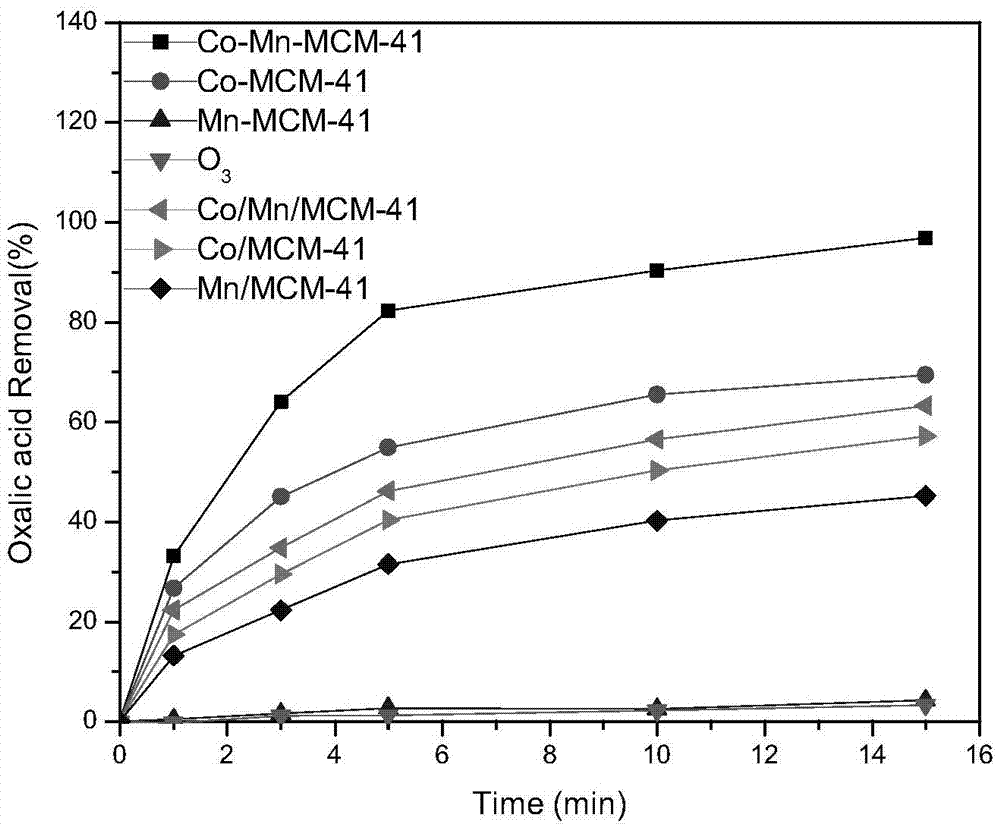

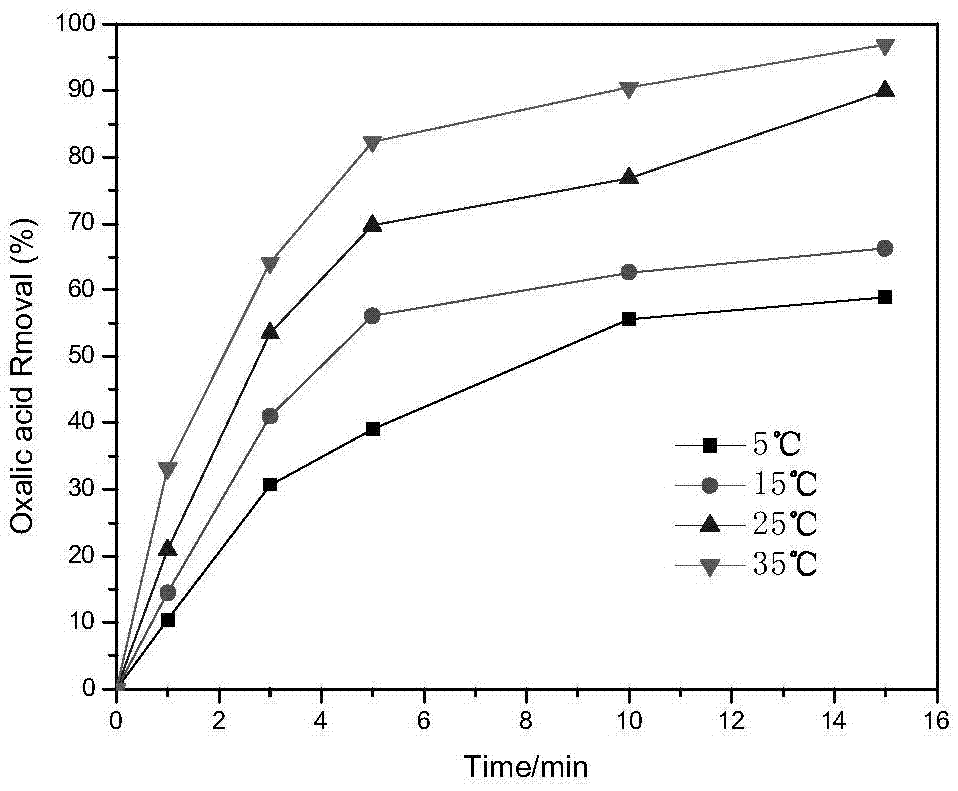

A technology of co-mn-mcm-41 and molecular sieve, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, water pollutants, etc., can solve the problems of time-consuming, cumbersome operation, easy to block channels, etc., to shorten the reaction time, catalyze The effect of high activity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of Co-Mn-MCM-41 molecular sieve, its raw material is as follows: 28.42gNa 2 SiO 3 9H 2 O, 0.243g cobalt nitrate, 0.204g manganese acetate, 7.28g CTAB, 100mL deionized water.

[0031] Its preparation method comprises the following steps:

[0032] 1) Na 2 SiO 3 9H 2 O was dissolved in 65ml deionized water, stirred to dissolve;

[0033] 2) Dissolve cobalt nitrate and manganese acetate in 10ml deionized water and add to the above solution, continue to stir for 15min, add dropwise 2mol L -1 Sulfuric acid solution until a sol appears, and continue to stir for 30 minutes;

[0034] 3) Dissolve CTAB in the remaining deionized water, add to the above solution and stir for 30 minutes, adjust the pH=10.5-11 to obtain the mixture;

[0035] 4) The mixture was crystallized at 145°C for 48h, cooled to room temperature, filtered and washed, and the washed crystalline product was dried at 80°C under vacuum, flattened, calcined in a muffle furnace at 550°C for 5h, and groun...

Embodiment 2

[0037] A kind of Co-Mn-MCM-41 molecular sieve, its raw material is as follows: 0.1molNa 2 SiO 3 9H 2 O, 0.182g cobalt nitrate, 0.153g manganese acetate, 7.28g CTAB, 100mL deionized water.

[0038] Its preparation method comprises the following steps:

[0039] 1) Na 2 SiO 3 9H 2 O was dissolved in 65ml deionized water, stirred and dissolved under a mechanical stirrer;

[0040] 2) Dissolve cobalt nitrate and manganese acetate in 10ml deionized water and add to the above solution, continue to stir for 15min, add dropwise 2mol L -1 Continue to stir the sulfuric acid solution for 30 minutes until the sol appears;

[0041] 3) Dissolve CTAB in 25ml of deionized water, add to the above solution and stir for 30min, adjust the pH=10.5~11 to obtain the mixture;

[0042] 4) The mixture was crystallized at 145°C for 48h, cooled to room temperature, filtered and washed, and the washed crystalline product was dried at 80°C under vacuum, flattened, calcined in a muffle furnace at 550°...

Embodiment 3

[0044] A kind of Co-Mn-MCM-41 molecular sieve, its raw material is as follows: 0.1molNa 2 SiO 3 9H 2 O, 1.25mmol cobalt nitrate, 1.25mmol manganese acetate, 0.01mol CTAB, 108mL deionized water.

[0045] Its preparation method comprises the following steps:

[0046] 1) Na 2 SiO 3 9H 2 O was dissolved in 65ml deionized water, stirred to dissolve;

[0047] 2) Dissolve cobalt nitrate and manganese acetate in 20ml deionized water and add to the above solution, continue to stir for 15min, add dropwise 2mol L -1 Sulfuric acid solution until a sol appears, and continue to stir for 25 minutes;

[0048]3) Dissolve CTAB in the remaining deionized water, add to the above solution and stir for 30 minutes, adjust the pH=10.5-11 to obtain the mixture;

[0049] 4) The mixture was crystallized at 135°C for 55h, cooled to room temperature, filtered and washed, and the washed crystalline product was dried at 80°C under vacuum, flattened, calcined in a muffle furnace at 650°C for 5h, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com