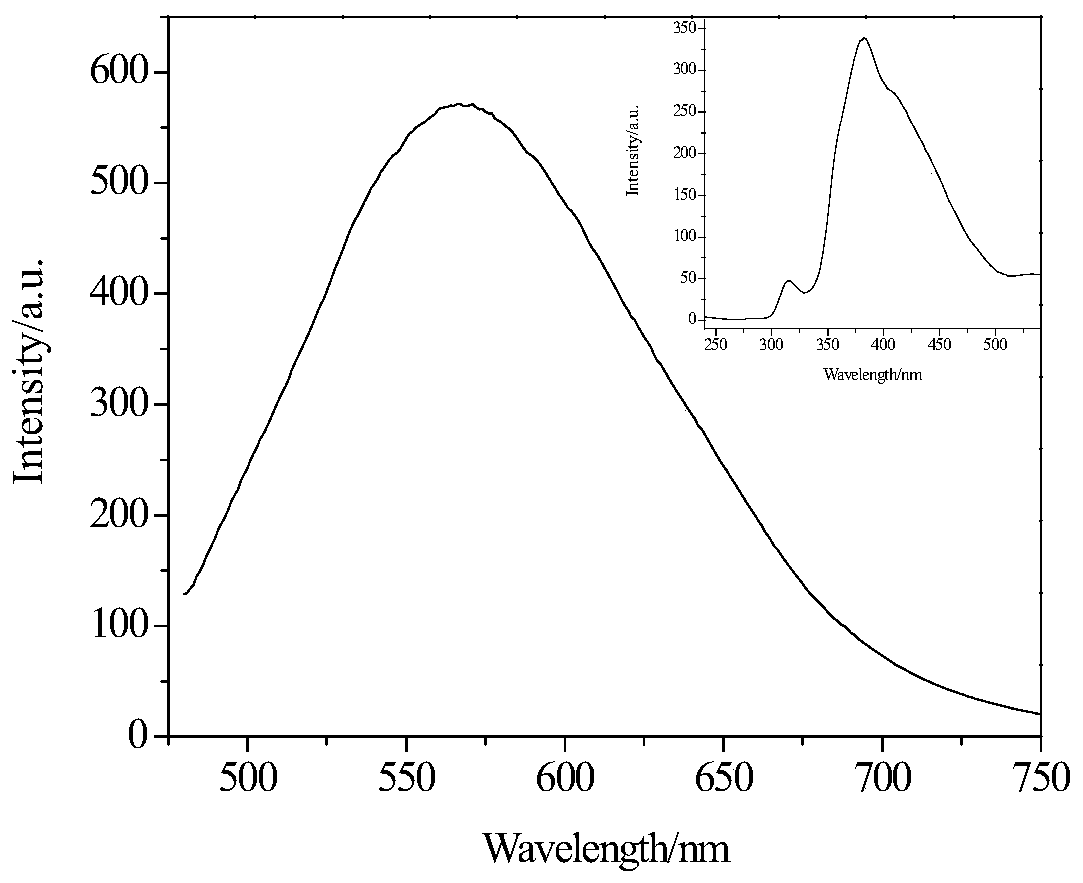

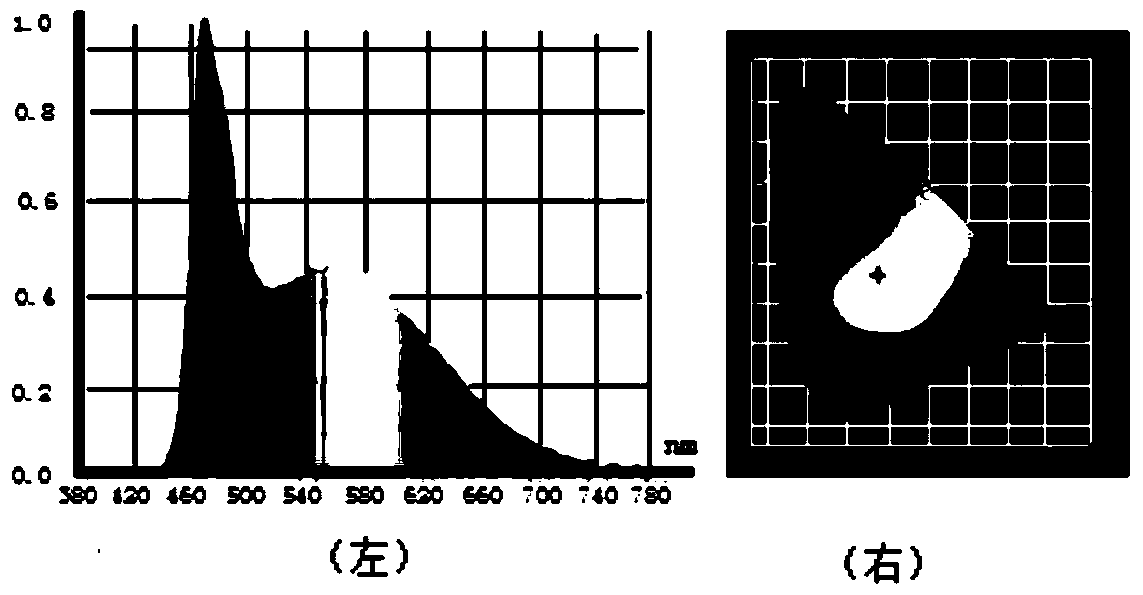

A preparation method of yellow light silica gel with both light emitting and encapsulating functions and its application in white light LED

A yellow light and silica gel technology, applied in chemical instruments and methods, luminescent materials, energy-saving lighting, etc., can solve problems such as affecting the luminous performance of LEDs, and achieve the effects of improving uneven dispersion, good optical uniformity, and improving luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

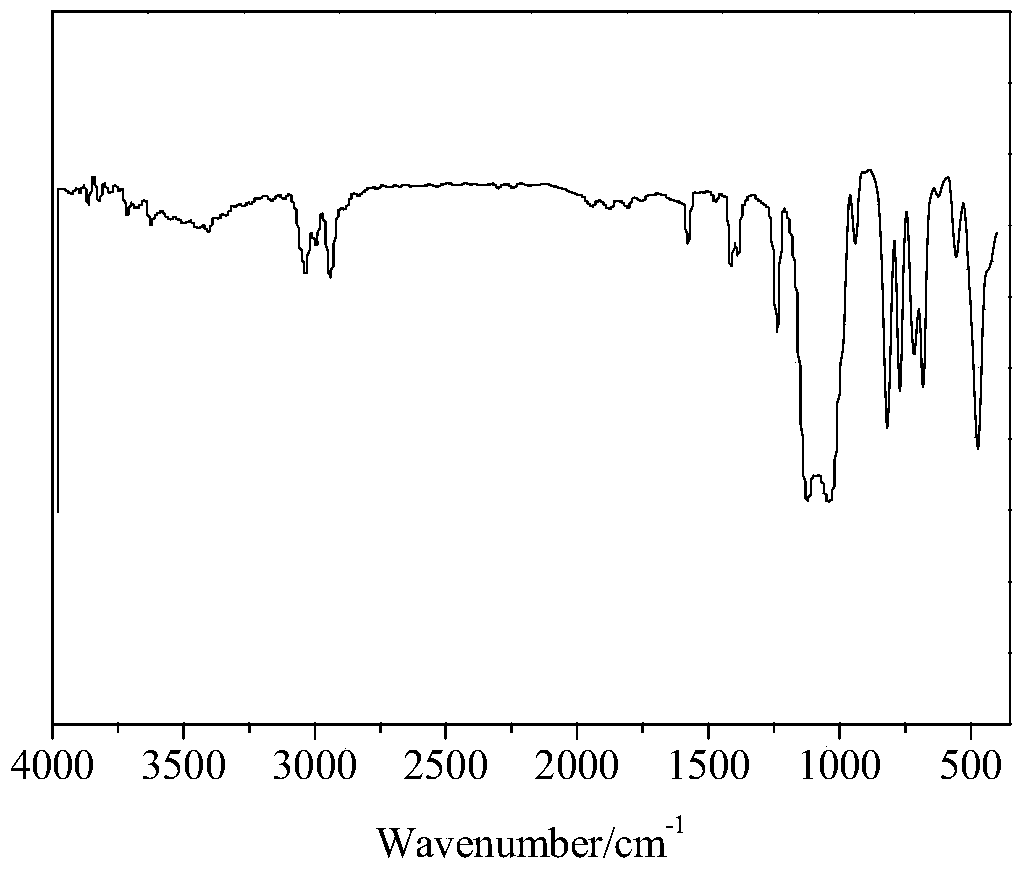

[0048] 1. Preparation of surface-modified yellow hydrotalcite

[0049] (1.1) Preparation of 2-p-biphenyl-8-hydroxyquinoline

[0050] Dissolve 3g of 4-bromobiphenyl in 15mL of anhydrous ether, under the protection of argon, add 0.1g of lithium metal, stir rapidly for 10 min, dissolve 0.8g of 8-hydroxyquinoline in 10mL of anhydrous ether, add In the above reaction system, stir rapidly, wait for 30 min to react, and the reaction ends. The product was poured into ice water to crystallize, filtered, washed and dried to obtain the crude product. The crude product was purified by chromatographic column to obtain 2-p-biphenyl-8-hydroxyquinoline.

[0051] (1.2) will contain 0.01mol ZnCl 2 , 0.1mol MgCl 2 and 0.024mol AlCl 3 The aqueous solution is prepared as a ternary mixed solution A, in which Al 3+ The concentration is 0.4M;

[0052] (1.3) Pre-mix 5 g of 2-p-biphenyl-8-hydroxyquinoline prepared in step 1 (1.1) in 30 mL of 1M sodium dodecylbenzenesulfonate aqueous solution to...

Embodiment 2

[0073] 1. Preparation of surface-modified yellow hydrotalcite

[0074] (1.1) Preparation of 2-p-biphenyl-8-hydroxyquinoline

[0075] Dissolve 5g of 4-bromobiphenyl in 20mL of anhydrous ether, under the protection of argon, add 0.3g of lithium metal, stir rapidly for 20 min, dissolve 0.5g of 8-hydroxyquinoline in 10mL of anhydrous ether, add In the above reaction system, stir rapidly, wait for 20 min to react, and the reaction ends. The product was poured into ice water to crystallize, filtered, washed and dried to obtain the crude product. The crude product was purified by chromatographic column to obtain 2-p-biphenyl-8-hydroxyquinoline.

[0076] (1.2) will contain 0.05mol ZnCl 2 , 0.3mol Ni(NO 3 ) 2 and 0.09mol Fe(NO 3 ) 2 The aqueous solution is prepared as a ternary mixed solution A, in which Fe 3+ The concentration is 0.9M;

[0077] (1.3) Pre-mix 4 g of 2-p-biphenyl-8-hydroxyquinoline prepared in step (1.1) with 27 mL of 2M sodium stearate aqueous solution to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com