Carbon nano tube/porous ceramic hollow fiber composite ultrafiltration membrane as well as preparation method and application thereof

A technology of porous ceramics and carbon nanotubes, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the increase of gas and liquid mass transfer resistance in the pores of composite membranes, limiting the growth of carbon nanotubes, and the influence of structure and morphology, etc. To achieve the effect of large-area growth, strong tunable denaturation, and enhanced separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

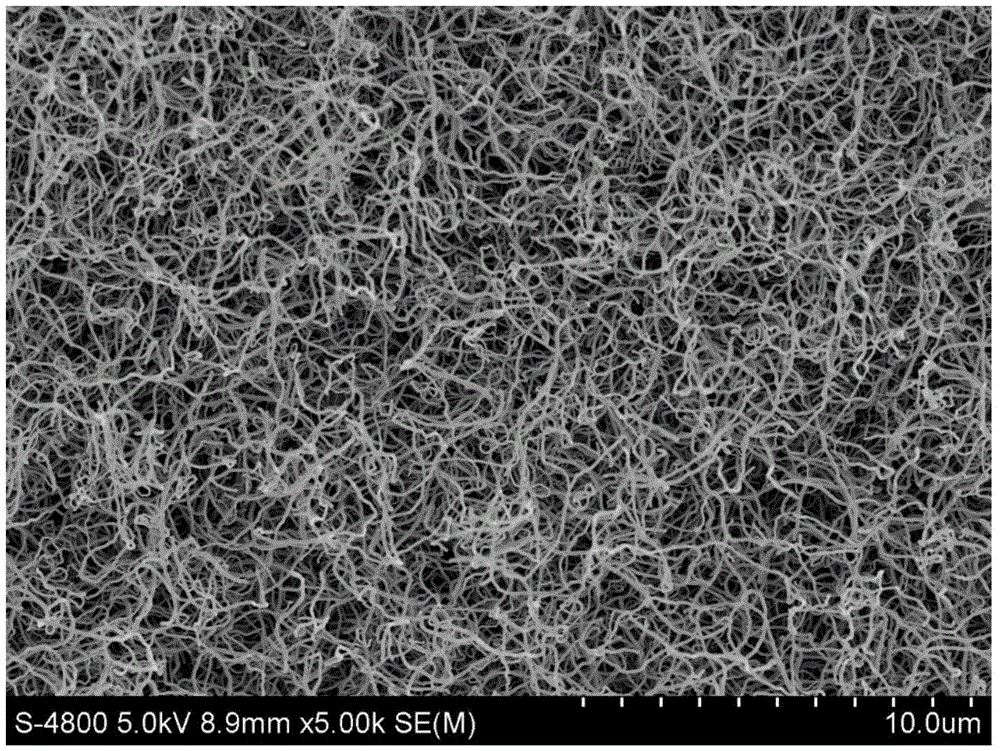

[0034] Example 1: Preparation of carbon nanotube / porous ceramic hollow fiber composite ultrafiltration membrane

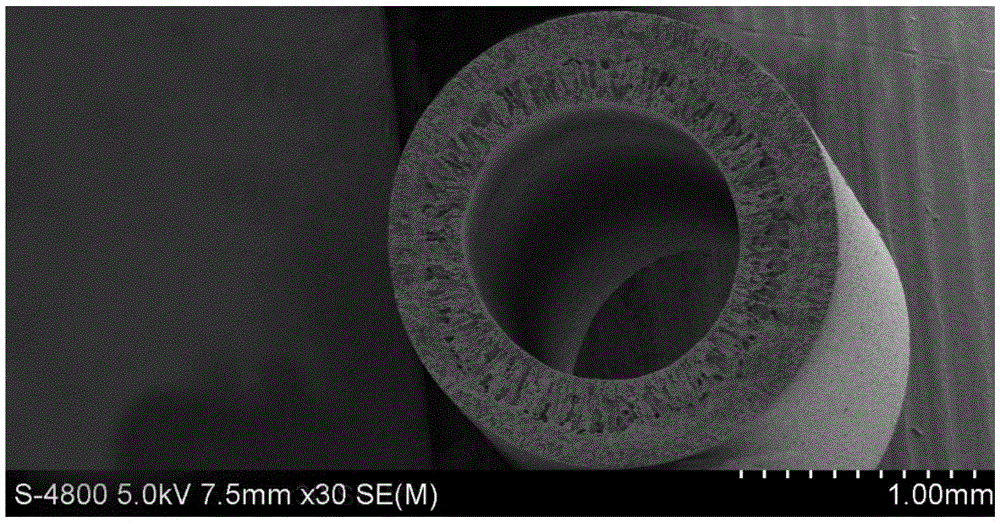

[0035] The mullite hollow fiber ceramic membrane with an average pore size of 1.0 μm is used as a carrier to prepare a carbon nanotube / porous ceramic hollow fiber composite ultrafiltration membrane with a pore size of <100 nm. The steps are:

[0036] The first step, the pretreatment of the carrier

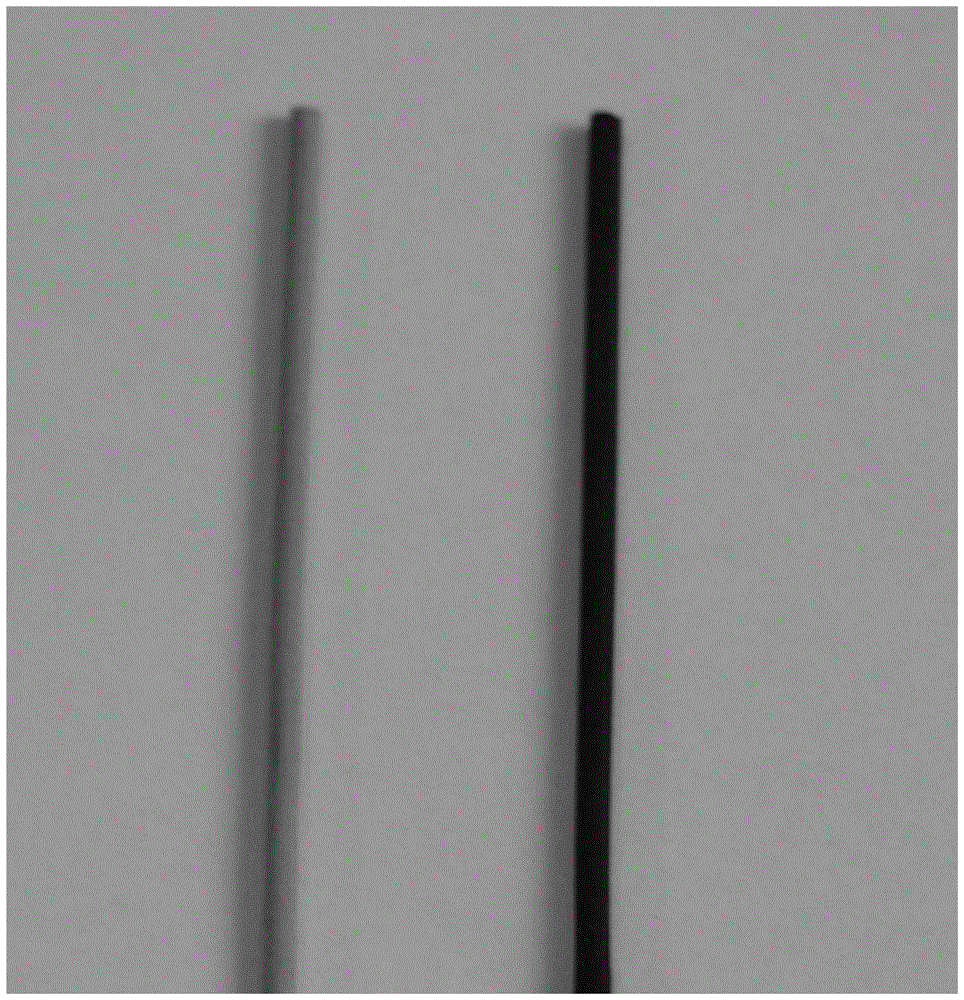

[0037] A mullite hollow fiber ceramic membrane with a pore size of 1.0 μm (see figure 1 The picture on the left) was ultrasonically oscillated with absolute ethanol for 1 hour, then washed with deionized water until neutral, and dried at 100°C for 2 hours to obtain the treated carrier;

[0038] In the second step, the Ni(NO 3 ) 2 Prepare a solution with a mass concentration of 20%, and use dip-coating (dipping coating) method to coat Ni(NO 3 ) 2 The solution was coated on the treated carrier, dried at 80°C for 1 hour, and then baked in a muffle furnace at 400°C for...

Embodiment 2

[0045] Example 2: Preparation of carbon nanotube / porous ceramic hollow fiber composite ultrafiltration membrane

[0046] Al with an average pore size of 1.0 μm 2 o 3 The hollow fiber ceramic membrane is used as a carrier to prepare a carbon nanotube / porous ceramic hollow fiber composite ultrafiltration membrane with a pore size of <100nm. The steps are:

[0047] The first step, the pretreatment of the carrier

[0048] Al as a carrier with a pore size of 1.0 μm 2 o 3 The hollow fiber ceramic membrane was ultrasonically oscillated with absolute ethanol for 1 hour, then washed with deionized water until neutral, and dried at 100°C for 2 hours to obtain the treated carrier;

[0049] In the second step, the Ni(NO 3 ) 2 Prepare a solution with a mass concentration of 10%, and use dip-coating (dipping coating) to coat Ni(NO 3 ) 2 The solution was coated on the treated carrier, dried at 80°C for 1 hour, and then baked in a muffle furnace at 350°C for 2 hours. Through x-ray di...

Embodiment 3

[0053] Example 3: Preparation of carbon nanotube / porous ceramic hollow fiber composite ultrafiltration membrane

[0054] ZrO with an average pore size of 1.0 μm 2 The hollow fiber ceramic membrane is used as a carrier to prepare a carbon nanotube / porous ceramic hollow fiber composite ultrafiltration membrane with a pore size of <100nm. The steps are:

[0055] The first step, the pretreatment of the carrier

[0056] ZrO with a pore size of 1.0 μm was used as the carrier 2 The hollow fiber ceramic membrane was ultrasonically oscillated with absolute ethanol for 1 hour, then washed with deionized water until neutral, and dried at 100°C for 2 hours to obtain the treated carrier;

[0057] In the second step, the Ni(NO 3 ) 2 Prepare a solution with a mass concentration of 30%, and use dip-coating (dipping coating) method to coat Ni(NO 3 ) 2 The solution is coated on the treated carrier, dried at 80° C. for 1 hour, and then baked in a muffle furnace at 300-400° C. for 2 hours. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com