Carbon quantum dot and titanium codoped mesoporous silica composite photocatalyst

A technology of mesoporous silica and mesoporous silica, applied in the field of photocatalysis, achieves high specific surface area, convenient operation and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

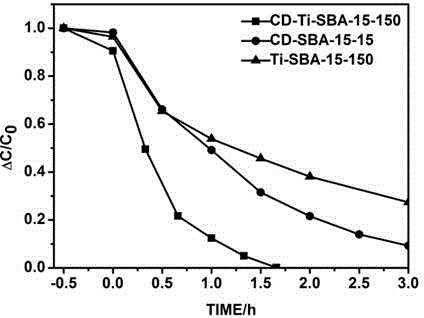

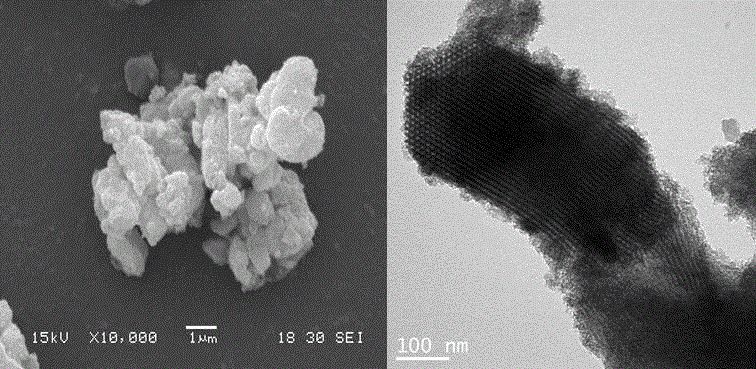

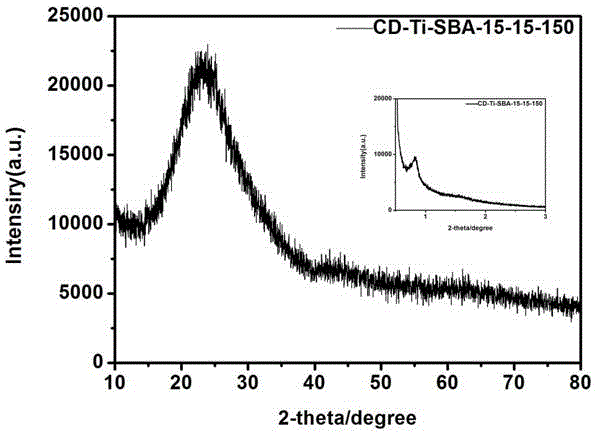

Embodiment 1

[0029] Weigh 1.33g of P123, 1.467g of chloride in a 100ml three-neck flask, dissolve in 20ml of 4M hydrochloric acid solution, add 20ml of deionized water, stir vigorously with mechanical stirring for 3 hours at 38°C to dissolve, reduce the stirring speed to avoid a large number of bubbles, A mixed solution of 3ml tetraethyl orthosilicate, 200ul carbon quantum dots and 20ul tetrabutyl titanate was added, stirred for another two minutes, and left to stand at 38°C for 24h. Transfer to a tetrafluoroethylene hydrothermal kettle, heat at 100°C for 24 hours, cool, filter and wash with water, wash with water three times, and dry in a vacuum oven at 60°C for 12 hours to obtain a sample. After the template agent is extracted, the sample is placed in a tube furnace, and the temperature is programmed to rise in a nitrogen atmosphere at a rate of 1°C / min, and it is calcined at 450°C for four hours, and then cooled naturally to obtain carbon quantum dots and titanium co-doping mesoporous s...

Embodiment 2

[0031] Weigh 1.33g of P123, 1.467g of chloride in a 100ml three-neck flask, dissolve in 20ml of 4M hydrochloric acid solution, add 20ml of deionized water, stir vigorously with mechanical stirring for 3 hours at 38°C to dissolve, reduce the stirring speed to avoid a large number of bubbles, Add 3ml tetraethyl orthosilicate, 200ul carbon quantum dots mixed solution, stir for two minutes, and let stand at 38°C for 24h. Transfer to a tetrafluoroethylene hydrothermal kettle, heat at 100°C for 24 hours, cool, filter and wash with water, wash with water three times, and dry in a vacuum oven at 60°C for 12 hours to obtain a sample. After the template agent is extracted, the sample is placed in a tube furnace, and the temperature is programmed to rise in a nitrogen atmosphere at a rate of 1°C / min, and it is calcined at 450°C for four hours, and then cooled naturally to obtain carbon quantum dot-doped mesoporous pores. Silica composite photocatalyst.

Embodiment 3

[0033] Weigh 1.33g of P123, 1.467g of chloride in a 100ml three-neck flask, dissolve in 20ml of 4M hydrochloric acid solution, add 20ml of deionized water, stir vigorously with mechanical stirring for 3 hours at 38°C to dissolve, reduce the stirring speed to avoid a large number of bubbles, A mixed solution of 3ml of tetrabutyl titanate and 3ml of tetrabutyl titanate was added, stirred for another two minutes, and left to stand at 38°C for 24h. Transfer to a tetrafluoroethylene hydrothermal kettle, heat at 100°C for 24 hours, cool, filter and wash with water, wash with water three times, and dry in a vacuum oven at 60°C for 12 hours to obtain a sample. After extracting the template agent, the sample was placed in a tube furnace, and the temperature was raised under a nitrogen atmosphere at a rate of 1°C / min, then raised to 450°C for four hours and then cooled naturally to obtain titanium-doped mesoporous silica. composite photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com