Environment-friendly carbon-based slow-release fertilizer and preparation method thereof

An environmentally friendly, slow-release fertilizer technology, applied in organic fertilizers, fertilization devices, excretion of fertilizers, etc., can solve the problems of non-renewable raw materials, single function, negative impact on soil quality, etc. the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

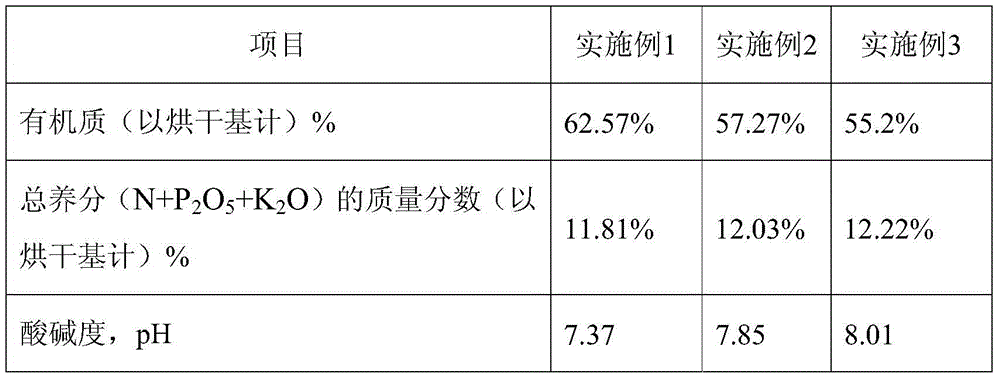

Examples

Embodiment 1

[0029] Embodiment 1: Preparation of environment-friendly carbon-based slow-release fertilizer

[0030] 1) Corn stalk charcoal (mass moisture content 15%), with a total nutrient content of 6.3%, is crushed and passed through a 40-mesh sieve.

[0031] 2) The organic fertilizer is selected to use pig manure as the main raw material, and the organic fertilizer obtained through high-temperature aerobic fermentation has a total nutrient content of 7.5%, and other quality indicators meet the requirements of the NY525-2012 standard; the inorganic fertilizer selects nitrogen fertilizer, potash fertilizer and The compound fertilizer of phosphate fertilizer has a total nutrient content of 45%. The basic fertilizer is obtained by mixing organic fertilizer and inorganic fertilizer according to the mass ratio of 3:1. The basic fertilizer is crushed and passed through a 40-mesh sieve.

[0032] 3) Mix and stir the corn stalk charcoal treated in step 1) and the basic fertilizer treated in step...

Embodiment 2

[0034] Embodiment 2: Preparation of environment-friendly carbon-based slow-release fertilizer

[0035] 1) Corn stalk charcoal (mass moisture content 15%), with a total nutrient content of 6.3%, is crushed and passed through a 40-mesh sieve.

[0036] 2) The organic fertilizer is selected from pig manure as the main raw material, and the organic fertilizer obtained by high-temperature aerobic fermentation has a total nutrient content of 7.5%, and other quality indicators meet the requirements of the NY525-2012 standard; its total nutrient content is 7.5% The inorganic fertilizer is compound fertilizer, whose total nutrient content is 54%. The basic fertilizer is obtained by mixing the organic fertilizer and the inorganic fertilizer according to the mass ratio of 4:1. The basic fertilizer is crushed and passed through a 40-mesh sieve.

[0037] 3) Mix and stir the corn stalk charcoal treated in step 1) and the basic fertilizer treated in step 2) according to the mass ratio of 50:5...

Embodiment 3

[0039] Example 3: Preparation of environmentally friendly carbon-based slow-release fertilizer

[0040] 1) Corn stalk charcoal (mass moisture content 15%), with a total nutrient content of 6.3%, is crushed and passed through a 40-mesh sieve.

[0041] 2) The organic fertilizer is selected from pig manure as the main raw material, and the organic fertilizer obtained by high-temperature aerobic fermentation has a total nutrient content of 7.5%, and other quality indicators meet the requirements of the NY525-2012 standard; its total nutrient content is 7.5% The inorganic fertilizer is compound fertilizer, whose total nutrient content is 54%. The organic fertilizer and inorganic fertilizer are mixed according to the mass ratio of 5:1 to obtain the basic fertilizer, and the basic fertilizer is crushed and passed through a 40-mesh sieve.

[0042] 3) Mix and stir the corn stalk charcoal treated in step 1) and the basic fertilizer treated in step 2) according to the mass ratio of 40:60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com