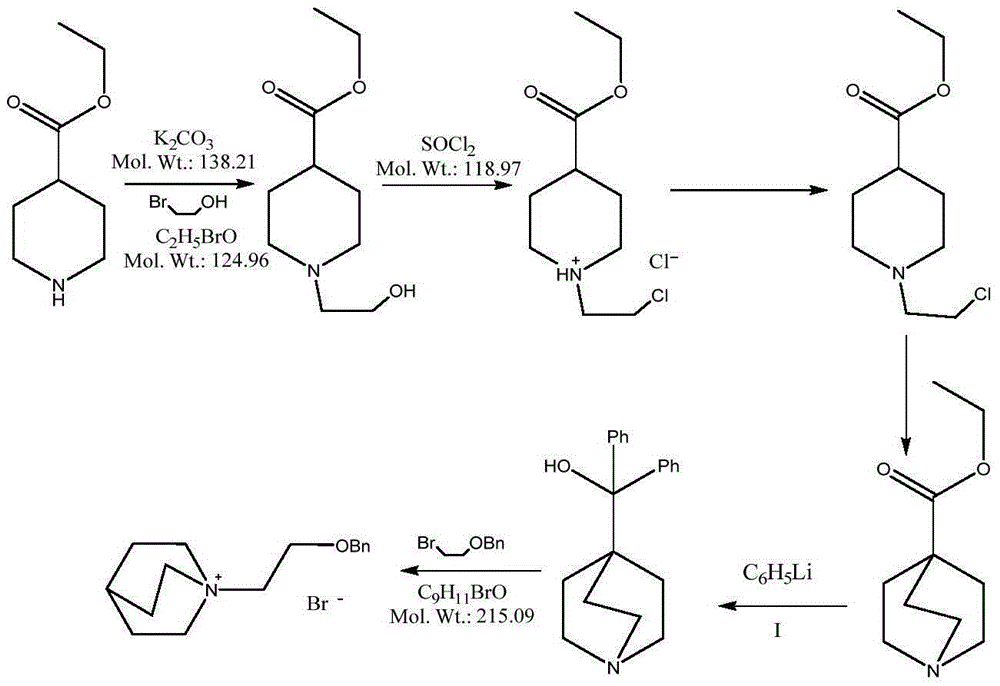

Preparation method of umeclidinium bromide

A technology of umeclidinium bromide and raw materials, applied in the field of preparation of umeclidinium bromide, can solve the problems of high price of lithium reagents, harsh use conditions, difficult storage and the like, and achieve the effects of mature equipment, mild reaction conditions and lower refrigeration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

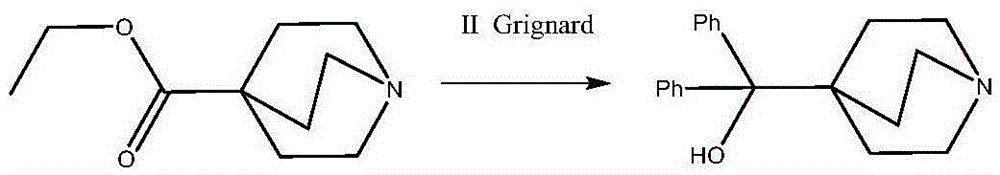

Method used

Image

Examples

Embodiment 1

[0017] Preparation of phenylmagnesium chloride: under nitrogen protection, add 55g (2.3mol) of metal magnesium tape brightened by sandpaper to 3 liters of tetrahydrofuran, drop 215g (1.91mol) of chlorobenzene, and proceed with slight heating, control the rate of addition to keep the reaction boiling, After about 1.5 hours, the dripping was completed, and after the dripping, the solution was heated under slight reflux for 30 minutes. Let cool and set aside.

Embodiment 2

[0019] Preparation of phenylmagnesium bromide: under the protection of argon, add 50.4g (2.1mol) of metal magnesium tape polished with sandpaper to 4.2 liters of anhydrous ether, drop 300g (1.91mol) of bromobenzene, add a grain of iodine to trigger, and hair dryer The slight heat reaction proceeded, and the addition rate was controlled to keep the reaction boiling, and the dripping was completed in about 1.5 hours, and then heated under slight reflux for 30 minutes after the dripping was completed. Let cool and set aside.

Embodiment 3

[0021] Preparation of crude product: ethyl azabicyclo[2.2.2]octane-4-carboxylate (135g, 0.736mol) was dissolved in 3L tetrahydrofuran, under the protection of nitrogen, the solution was cooled to -5~0°C, and 300g of brominated Grignard reagent prepared from benzene. After stirring at -5~0°C for 1 hour (sampling TLC to monitor the progress of the reaction). Add 50ml of water to quench. The liquids were separated, and the aqueous phase was extracted twice with 500 ml of tetrahydrofuran, the combined organic phases were washed with water, dried and filtered. Part of the solvent was removed under reduced pressure, and the remainder was kept at about 1 L. The residue was stirred at 20°C overnight for crystallization. Filter, wash (petroleum ether 2×200ml), and vacuum-dry the filter cake at 40°C to obtain 121.2g of yellow-white crystals, with a yield of 54.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com