Preparation method of modified carbon black/TPI (trans-1,4-polyisoprener)/rubber composite material for green tires

A green tire and modified carbon black technology, which is applied in special tires, tire parts, rolling resistance optimization, etc., can solve the problems of large surface energy, long processing time, and easy agglomeration, so as to improve rolling resistance and compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation of grafted modified carbon black:

[0020] (1) Add 50g carbon black and 300ml concentrated nitric acid into a three-necked flask, stir mechanically, heat in an oil bath, and react at 80°C for 10 hours. After the reaction is over, cool to room temperature, filter, and repeatedly wash with deionized water until the filtrate is neutral. Finally, the filter residue is dried at 75°C to obtain the product;

[0021] (2) Add 50g of the product obtained in step (1) and 12.5g of thionyl chloride into a three-necked flask, with toluene as the solvent, mechanical stirring, add 5 drops of triethylamine as acid binding agent, react in an ice bath for 30 minutes, and heat to 120°C Continue the reaction for 30 minutes, and the reaction product is rotary evaporated at 80°C to remove the unreacted thionyl chloride to obtain the product;

[0022] (3) Add 50g of the product obtained in step (2) into 25g polyethylene glycol 400, with toluene as the solvent, add 5 drops of dibutyltin ...

Embodiment 2

[0026] Preparation of grafted modified carbon black:

[0027] (1) Add 50g carbon black and 300ml hydrogen peroxide into a three-necked flask, stir mechanically, heat in an oil bath, and react at 80°C for 10 hours. After the reaction is over, cool to room temperature, filter, and repeatedly wash with deionized water until the filtrate is neutral. Finally, the filter residue is dried at 75°C to obtain the product;

[0028] (2) Add 50g and 18g toluene diisocyanate obtained in step (1) into a three-necked flask, with toluene as solvent, mechanical stirring, add 5 drops of triethylamine as acid binding agent, react in ice bath for 30min, heat to 120℃ to continue the reaction 30min, the reaction product was rotated at 80°C to remove unreacted toluene isocyanate, and the product was obtained;

[0029] (3) Add 50g of the product obtained in step (2) into 25g polyethylene glycol 400, with toluene as the solvent, add 5 drops of dibutyltin dilaurate as a catalyst, react in an ice bath for 30 ...

Embodiment 3

[0033] Preparation of grafted modified carbon black:

[0034] (1) Add 50g carbon black and 300ml concentrated nitric acid into a three-necked flask, stir mechanically, heat in an oil bath, and react at 80°C for 10 hours. After the reaction is over, cool to room temperature, filter, and repeatedly wash with deionized water until the filtrate is neutral. Finally, the filter residue is dried at 75°C to obtain the product;

[0035] (2) Add 50g of the product obtained in step (1) and 12.5g of thionyl chloride into a three-necked flask, with toluene as the solvent, mechanical stirring, add 5 drops of triethylamine as acid binding agent, react in an ice bath for 30 minutes, and heat to 120°C Continue the reaction for 30 minutes, and the reaction product is rotary evaporated at 80°C to remove the unreacted thionyl chloride to obtain the product;

[0036] (3) Add 50g of the product obtained in step (2) into 25g polyethylene glycol 400, with toluene as the solvent, add 5 drops of dibutyltin ...

PUM

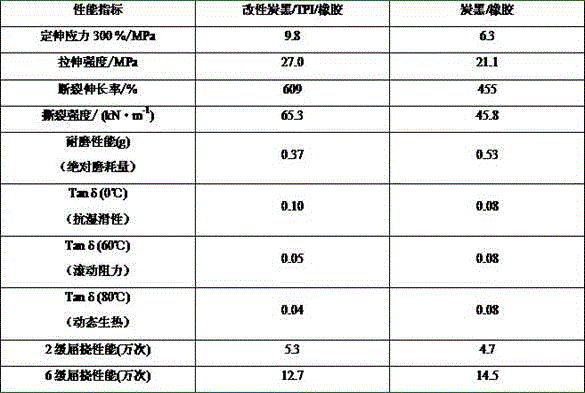

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com