A kind of preparation method of al-b-re master alloy

An intermediate alloy and intermediate frequency technology, which is applied in the field of materials and metallurgy, can solve the problems of material conductivity decline, achieve the effect of improving viscosity, avoiding rapid temperature rise, and ensuring smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

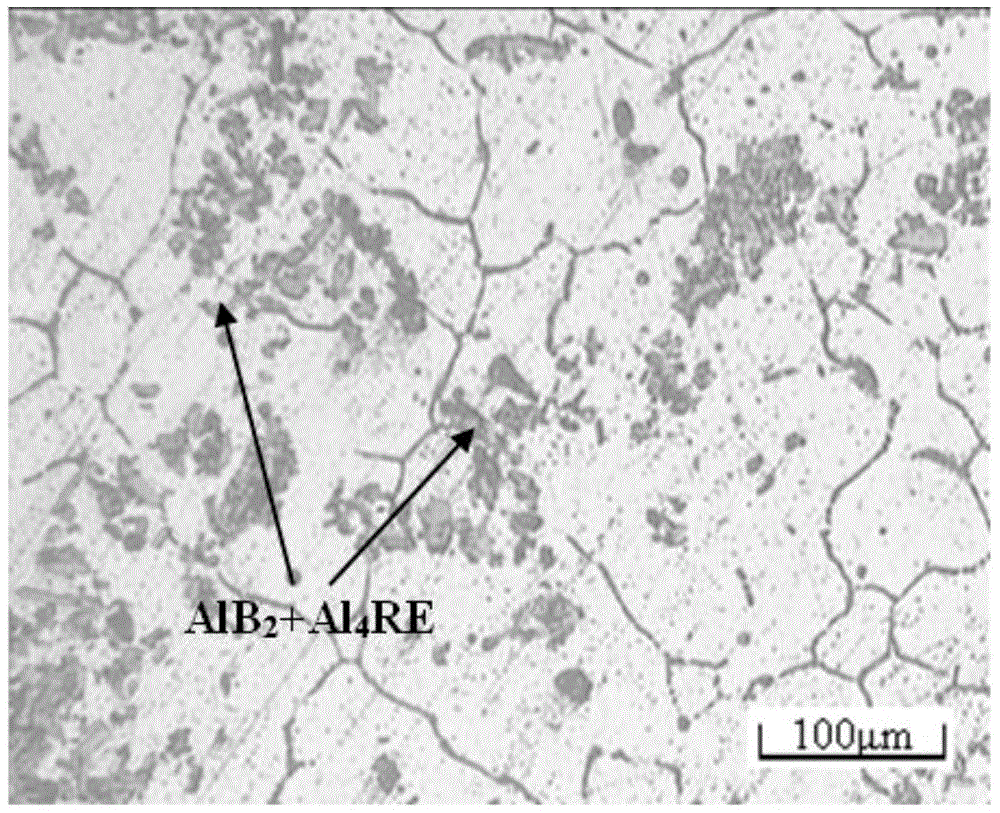

Embodiment 1

[0037] The preparation method of the present embodiment Al-3B-0.5RE master alloy, concrete steps are as follows:

[0038] (1) Raw material preparation: calculate the weight of each raw material according to the ratio of Al-3B-0.5RE master alloy, and take by weighing for subsequent use;

[0039] (2) Melting of pure aluminum: heat 995kg aluminum ingot to 700°C in an intermediate frequency induction furnace until the aluminum ingot is completely melted into molten aluminum, and remove impurities and oxide films on the surface of the molten aluminum;

[0040] (3) Add potassium cryolite powder: spread 20kg of potassium cryolite powder on the surface of molten aluminum;

[0041] (4)KBF 4 The first feeding: when the potassium cryolite powder is completely melted, add KBF to the molten aluminum for the first time while stirring 4 245kg; the feeding speed is controlled at 18kg / min to reduce KBF 4 The volatilization; feed KBF 4 Continue to stir for 8 minutes after the end, then let ...

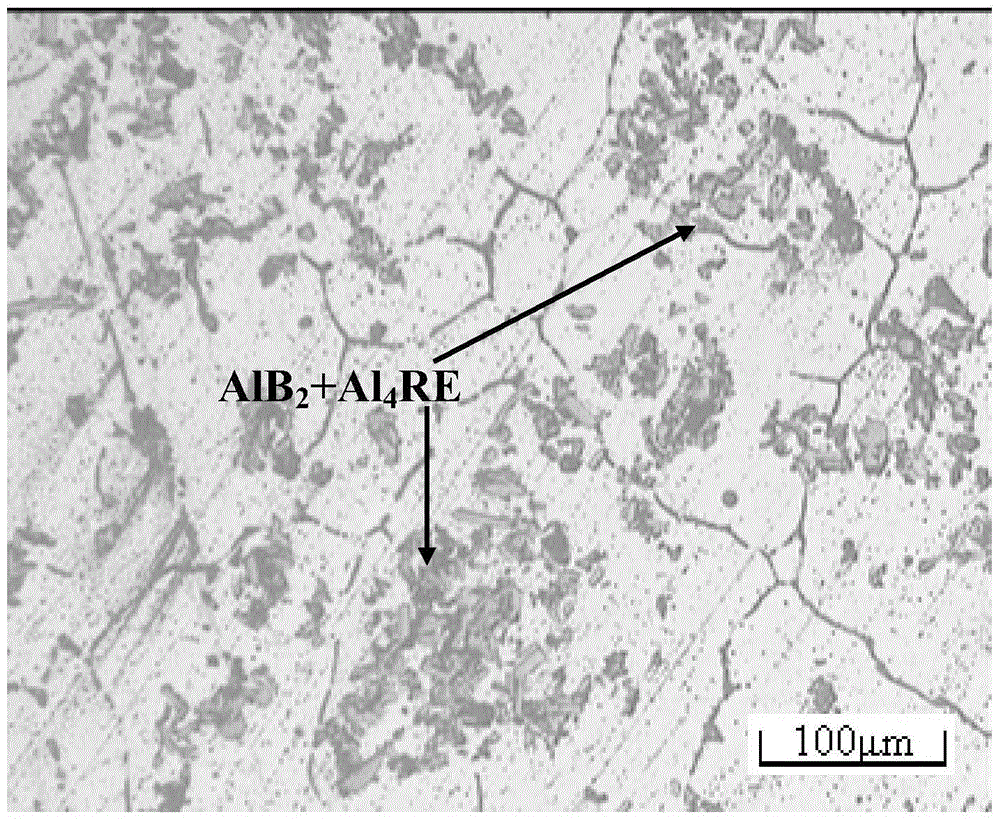

Embodiment 2

[0052] The preparation method of the present embodiment Al-4B-1RE master alloy, concrete steps are as follows:

[0053] (1) Raw material preparation: calculate the weight of each raw material according to the ratio of Al-4B-1RE master alloy, and take by weighing for subsequent use;

[0054] (2) Melting of pure aluminum: heat 985kg aluminum ingot to 680°C in an intermediate frequency induction furnace until the aluminum ingot is completely melted into molten aluminum, and remove impurities and oxide films on the surface of the molten aluminum;

[0055] (3) Add potassium cryolite powder: spread 25kg of potassium cryolite powder on the surface of molten aluminum;

[0056] (4)KBF 4 The first feeding: when the potassium cryolite powder is completely melted, add KBF to the molten aluminum for the first time while stirring 4 306kg; the feeding speed is controlled at 20kg / min to reduce KBF 4 volatilization; join KBF 4 Continue to stir for 5 minutes after the end, then let stand fo...

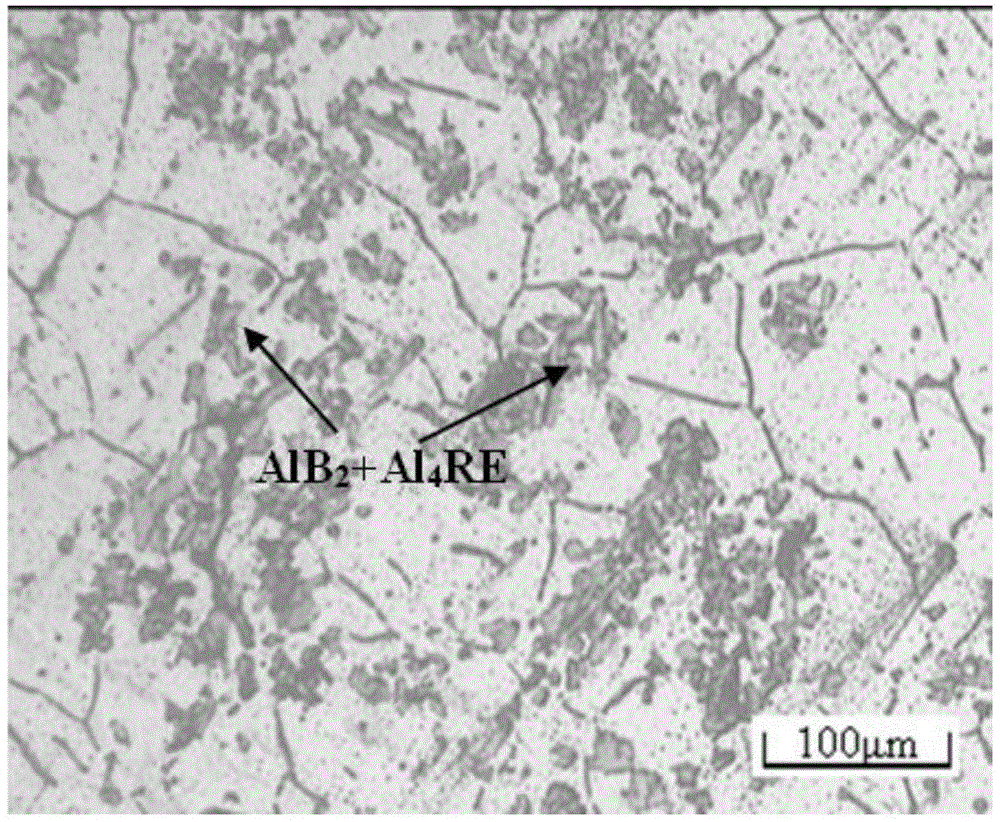

Embodiment 3

[0067] The preparation method of the present embodiment Al-5B-1RE master alloy, concrete steps are as follows:

[0068] (1) Raw material preparation: calculate the weight of each raw material according to the ratio of Al-5B-1RE master alloy, and take by weighing for subsequent use;

[0069] (2) Melting of pure aluminum: heat 975kg aluminum ingot to 720°C in an intermediate frequency induction furnace until the aluminum ingot is completely melted into molten aluminum, and remove impurities and oxide films on the surface of the molten aluminum;

[0070] (3) Add potassium cryolite powder: spread 15kg of potassium cryolite powder on the surface of molten aluminum;

[0071] (4)KBF 4 The first feeding: when the potassium cryolite powder is completely melted, add KBF to the molten aluminum for the first time while stirring 4 378kg; feeding speed is controlled at 15kg / min to reduce KBF 4 volatilization; join KBF 4 Continue to stir for 15 minutes after the end, then let stand for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com