Anti-electromagnetic interference magnetic flexible patch and preparation method thereof

An anti-electromagnetic interference, patch technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of weakening the receiving sensitivity of the system antenna 2, shortening the reading and writing distance of electronic tags, and not being light and easy to use. , to achieve the effect of light and simple use, easy industrial production, and good patch flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

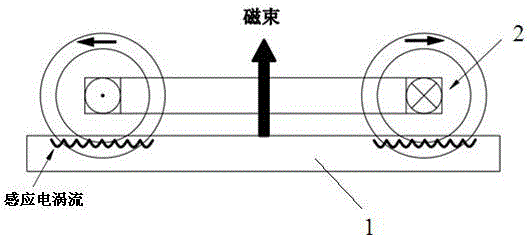

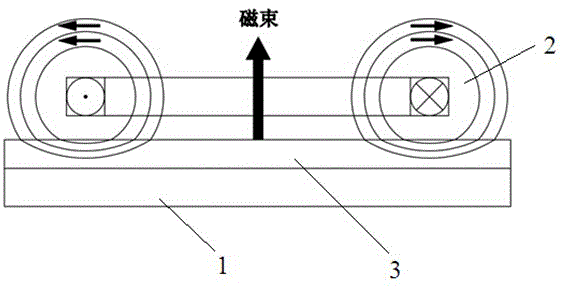

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The anti-electromagnetic interference magnetic flexible patch of this embodiment is composed of the following components:

[0028] Flat soft magnetic alloy powder Fe prepared by ball milling with a mass fraction of 90% 85 Si 9 al 6 , where 85, 9 and 6 represent the weight percentages of Fe element, Si element and Al element respectively; Fe 85 Si 9 al 6 The particle size is 50-100μm, the thickness is 0.5-1μm; the mass fraction is 9.9% propylene-ethylene copolymer (VM6102 from Exxon Mobil, USA); the mass fraction is 0.1% stearic acid, stearic acid is used as lubricant .

[0029] The preparation method of the anti-electromagnetic interference magnetic flexible patch of this embodiment includes the following steps:

[0030] (1) Flat soft magnetic alloy powder Fe prepared by ball milling 85 Si 9 al 6 Put it in a vacuum drying oven, dry it at 150°C for 1 hour, and take it out after cooling;

[0031] (2) Using a vibrating sieve, the flat soft magnetic alloy powder F...

Embodiment 2

[0037] The anti-electromagnetic interference magnetic flexible patch of this embodiment is composed of the following components:

[0038] Flat soft magnetic alloy powder Fe prepared by ball milling with a mass fraction of 85% 90 Si 7 Cr 3 , where 90, 7 and 3 represent the weight percent of Fe element, Si element and Cr element respectively; Fe 90 Si 7 Cr 3 The particle size is 30-75μm, the thickness is 0.5-1μm, the mass fraction is 14.9% propylene-ethylene copolymer (VM6102 from ExxonMobil, USA); the mass fraction is 0.1% paraffin oil, and the paraffin oil is used as a lubricant.

[0039] The preparation method of the anti-electromagnetic interference magnetic flexible patch of this embodiment includes the following steps:

[0040] (1) Flat soft magnetic alloy powder Fe prepared by ball milling 90 Si 7 Cr 3 Put it in a vacuum drying oven, dry it at 100°C for 2 hours, and take it out after cooling;

[0041] (2) Using a vibrating sieve, the flat soft magnetic alloy powd...

Embodiment 3

[0047] The anti-electromagnetic interference magnetic flexible patch of this embodiment is composed of the following components:

[0048] Flat soft magnetic alloy powder Fe prepared by ball milling with a mass fraction of 85% 87 Si 10 Cr 1 Ni 2 , where 87, 10, 1 and 2 represent the weight percentages of Fe element, Si element, Cr element and Ni element respectively; Fe 87 Si 10 Cr 1 Ni 2 The particle size is 75-150μm, and the thickness is 1-1.5μm; the mass fraction is 14.8% propylene-ethylene copolymer (select VM6102 from ExxonMobil, USA); the mass fraction is 0.2% zinc stearate, zinc stearate as a lubricant.

[0049] The preparation method of the anti-electromagnetic interference magnetic flexible patch of this embodiment includes the following steps:

[0050] (1) Flat soft magnetic alloy powder Fe prepared by ball milling 87 Si 10 Cr 1 Ni 2 Put it in a vacuum drying oven, dry it at 200°C for 1 hour, and take it out after cooling;

[0051] (2) Using a vibrating s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com