Integrated composite electrode for supercapacitor and preparation method of integrated composite electrode

A technology of supercapacitors and composite electrodes, applied in the field of capacitors, can solve the problems of short diffusion distance and low capacitance, and achieve the effects of improving contact interface, uniform growth and firm load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

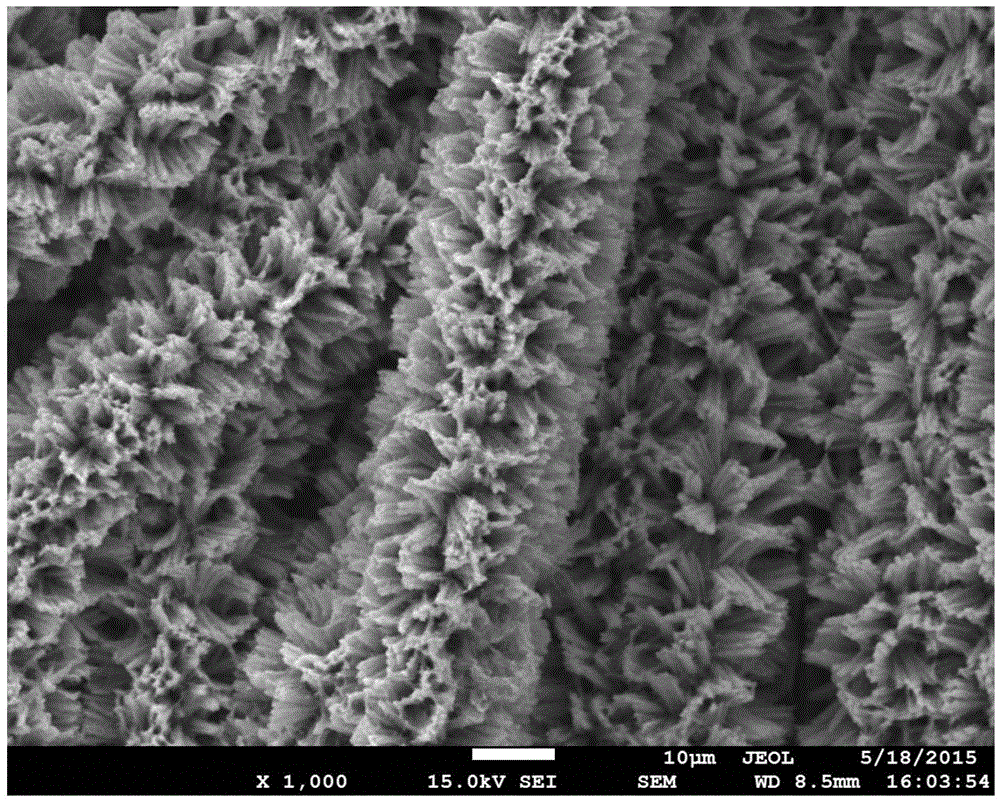

[0018] (1) Cut the commercial carbon cloth into a certain size (such as 1x2cm 2 ), then place the cut carbon cloth in dilute hydrochloric acid and deionized water for ultrasonic cleaning for 15 minutes, air-dry naturally, and set aside;

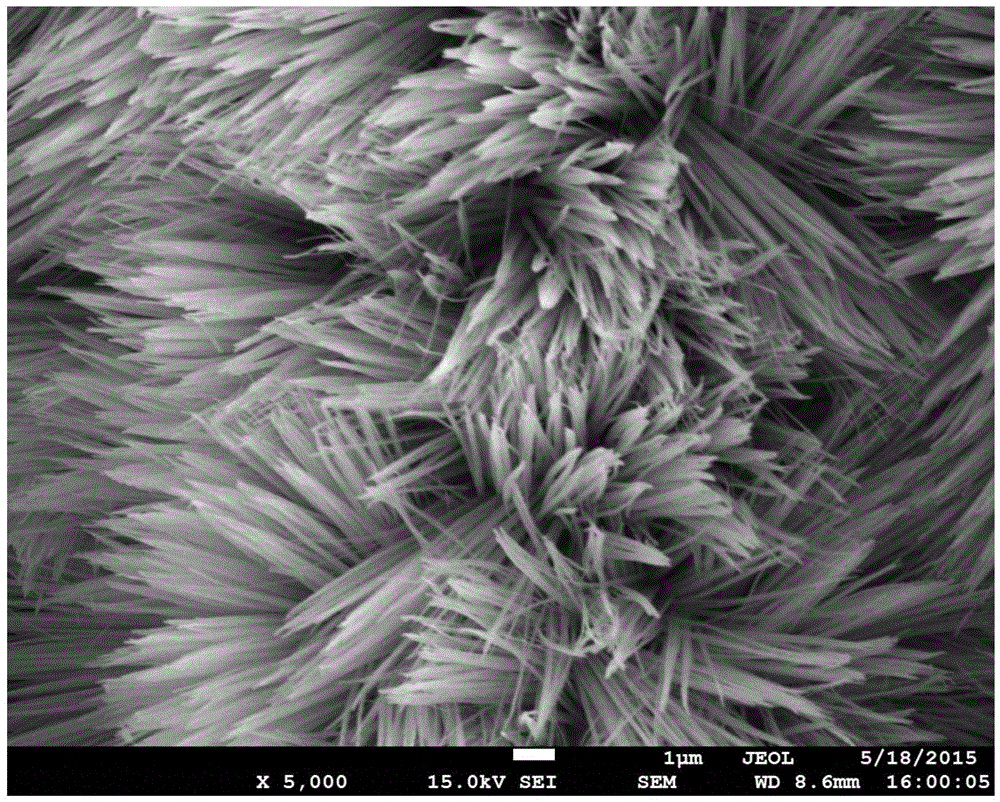

[0019] (2) Add 15mL deionized water into the reaction kettle, weigh 1mmol Co(No 3 ) 2 ·6H 2 O, 4 mmol NH 4 F, 5mmol urea, add deionized water under stirring until a transparent pink solution is formed, insert the prepared carbon cloth vertically and immerse it in the solution, seal the reaction kettle, raise the temperature of the reaction kettle to 100°C for 12 hours, and cool After reaching room temperature, the carbon cloth was taken out of the reaction kettle and placed in water and ethanol for ultrasonic cleaning several times, dried at 60 °C for 12 h, and then calcined at 300 °C for 2 h in an air atmosphere to grow Co on the surface of the carbon cloth. 3 o 4 nanowire arrays;

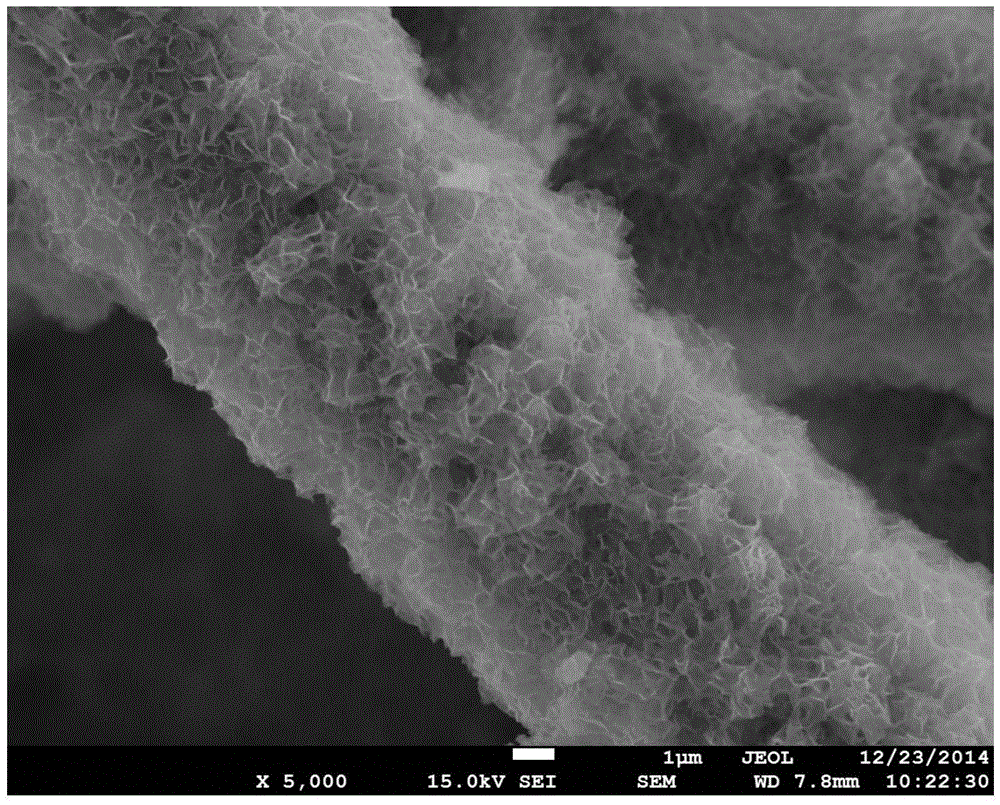

[0020] (3) Take 10 mL of deionized water and add it t...

Embodiment 2

[0022] (1) Cut the commercial carbon cloth into a certain size (such as 1x2cm 2 ), then place the cut carbon cloth in dilute hydrochloric acid and deionized water for ultrasonic cleaning for 15 minutes, air-dry naturally, and set aside;

[0023] (2) Add 15mL deionized water into the reaction kettle, weigh 1.2mmol Co(No 3 ) 2 ·6H 2 O, 5 mmol NH 4 F, 6mmol urea, add deionized water under stirring until a transparent pink solution is formed, insert the prepared carbon cloth vertically and immerse it in the solution, seal the reaction kettle, raise the temperature of the reaction kettle to 110°C for 10h, and cool After reaching room temperature, the carbon cloth was taken out of the reaction kettle and ultrasonically cleaned several times in water and ethanol respectively, dried at 60°C for 12 h, and then calcined at 320°C for 2 h in an air atmosphere to grow Co on the surface of the carbon cloth. 3 o 4 nanowire arrays;

[0024] (3) Take 10 mL of deionized water and add it t...

Embodiment 3

[0026] (1) Cut the commercial carbon cloth into a certain size (such as 1x2cm 2 ), then place the cut carbon cloth in dilute hydrochloric acid and deionized water for ultrasonic cleaning for 15 minutes, air-dry naturally, and set aside;

[0027] (2) Add 15mL deionized water into the reaction kettle, weigh 1.5mmol Co(No 3 ) 2 ·6H 2 O, 6 mmol NH 4 F, 7.5mmol urea, add deionized water under stirring until a transparent pink solution is formed, insert the prepared carbon cloth vertically and immerse it in the solution, seal the reaction kettle, raise the temperature of the reaction kettle to 120°C for 9 hours, After cooling to room temperature, the carbon cloth was taken out of the reaction kettle and ultrasonically cleaned several times in water and ethanol respectively, dried at 60 °C for 12 h, and then calcined at 350 °C for 2 h in an air atmosphere to grow Co on the surface of the carbon cloth. 3 o 4 nanowire arrays;

[0028] (3) Take 10 mL of deionized water and add it to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com