High-fiber mung bean protein peptide compound nutritional food and green production method thereof

A technology for mung bean protein and nutritious food, applied in the field of nutritious food processing, can solve problems such as food resource waste and environmental problems, and achieve the effects of convenient operation, convenient eating and excellent flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

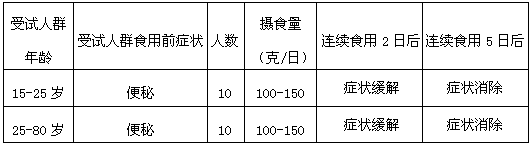

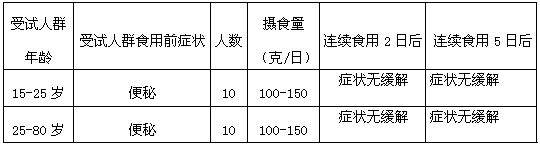

Image

Examples

Embodiment 1

[0036] is obtained by the following steps:

[0037] (1) Dynamic infiltration of mung bean

[0038] Choose high-quality mung beans that are free from moths, mildew, and impurities, wash them with drinking water at 20°C for 10 minutes, drain the water, put them in a soaking tank, add purified water that is 5 times the mass of mung beans, and use food-grade lemons. Adjust the pH of pure water to 6.8 with acid or sodium carbonate, stir and infiltrate at 15°C, the stirring speed is 60r / min, and the infiltration time is 9h, so that the mung bean is moistened and the mung bean skin is softened, and it is set aside;

[0039] (2) Heat preservation and reflux grinding

[0040] Put the material obtained in step (1) into the colloid mill, heat preservation and reflux at 25°C for 30 minutes, and use the high-speed relative motion of the movable and fixed tooth discs of the colloid mill and the bubbles and eddy currents generated during the reflux of the colloid mill to grind the material ...

Embodiment 2

[0048] is obtained by the following steps:

[0049] (1) Dynamic infiltration of mung bean

[0050] Choose high-quality mung beans without moths, mildew, and impurities, wash them with drinking water at 25°C for 5 minutes, drain the water, put them in a soaking tank, add pure water with 9 times the mass of mung beans, and use food-grade lemons. Adjust the pH of pure water to 7.0 with acid or sodium carbonate, stir and infiltrate at 25°C, the stirring rate is 150r / min, and the infiltration time is 12h, so that the mung bean is moistened and the mung bean skin is softened, and it is ready for use;

[0051] (2) Heat preservation and reflux grinding

[0052] Put the material obtained in step (1) into the colloid mill, heat-preserve and reflux at 32°C for 20 minutes, use the high-speed relative motion of the colloid mill’s movable and fixed tooth discs and the bubbles and eddy currents generated during the reflux of the colloid mill to grind the material and destroy it. The tight ...

Embodiment 3

[0060] is obtained by the following steps:

[0061] (1) Dynamic infiltration of mung bean

[0062] Choose high-quality mung beans without moths, mildew, and impurities, wash them with drinking water at 22°C for 8 minutes, drain the water, put them in a soaking tank, add pure water that is 7 times the mass of mung beans, and use food-grade lemons. Adjust the pH of pure water to 6.9 with acid or sodium carbonate, stir and infiltrate at 20°C, the stirring rate is 100r / min, and the infiltration time is 10h, so that the mung bean is moistened and the mung bean skin is softened, and it is ready for use;

[0063] (2) Heat preservation and reflux grinding

[0064] Put the material obtained in step (1) into the colloid mill, heat preservation and reflux at 28°C for 25 minutes, and grind the material with the help of the high-speed relative motion of the movable and fixed tooth discs of the colloid mill and the bubbles and eddy currents generated during the reflux of the material liquid,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com