A cu/tio 2 Nanorod catalyst and its preparation method and application in wastewater wet oxidation

A catalyst and nanorod technology, which is applied in the fields of catalytic chemistry and environmental water treatment, can solve problems such as no patent reports, and achieve the effects of shortening reaction time, promoting collision probability, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

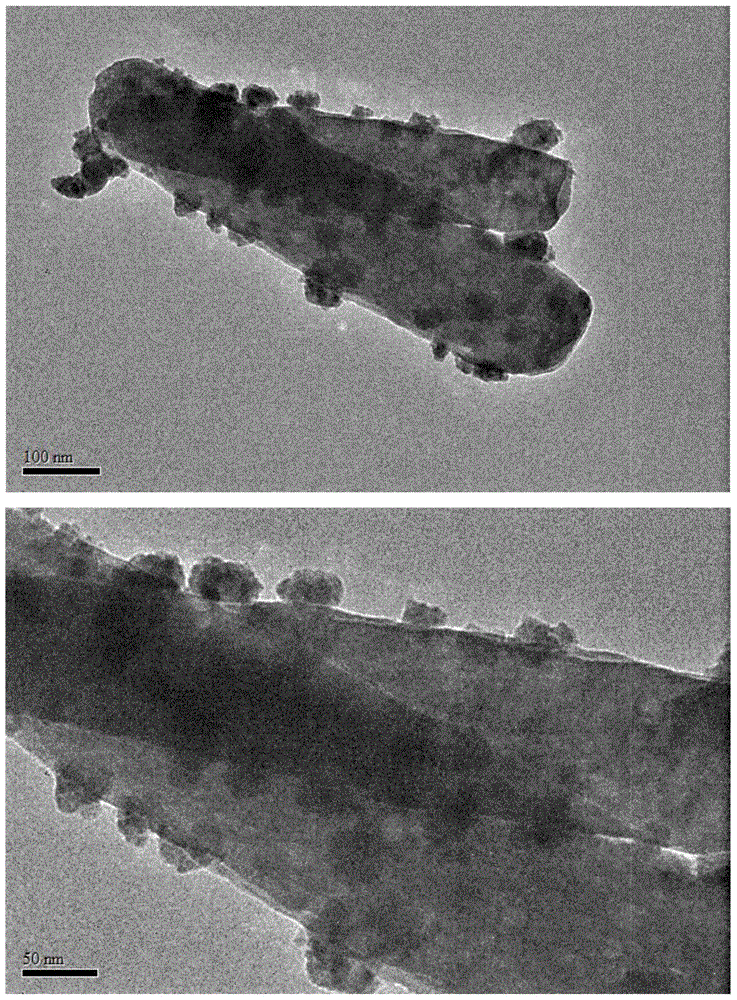

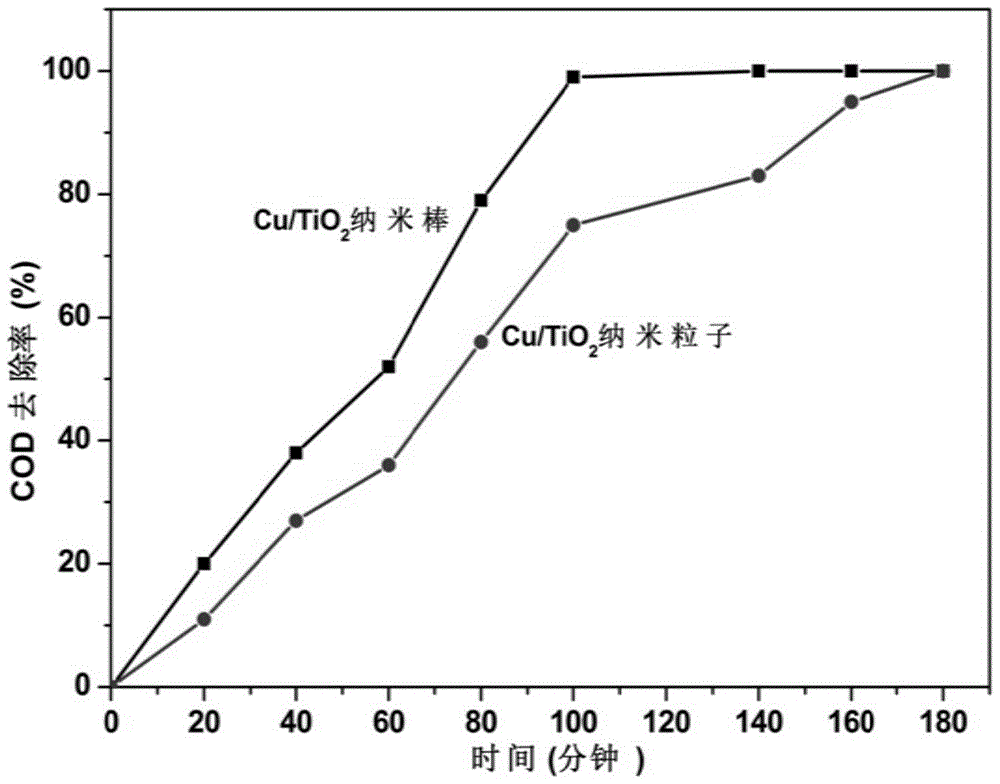

[0028] Under magnetic stirring (stirring speed 600r / min), 0.1g Cu(NO 3 ) 2 , 11g tetrabutyl titanate and 5g hexamethylenetetramine were dissolved in 10wt% ethylene glycol aqueous solution. Under a nitrogen atmosphere, react in a microwave reactor with a power of 300W for 10 minutes. Cool down to room temperature, filter the precipitate, wash with hot deionized water, dry at 90°C for 12 hours, and roast in a muffle furnace at 500°C for 4h to obtain Cu / TiO 2 nanorod catalysts. The prepared Cu / TiO 2 Catalysts were characterized by TEM. From figure 1 It can be seen that the carrier TiO 2The particle diameter is 80-120nm, and the length is about 400-600nm. The active metal copper is evenly dispersed on the surface of the carrier, and the diameter of the copper particles is 8-15nm.

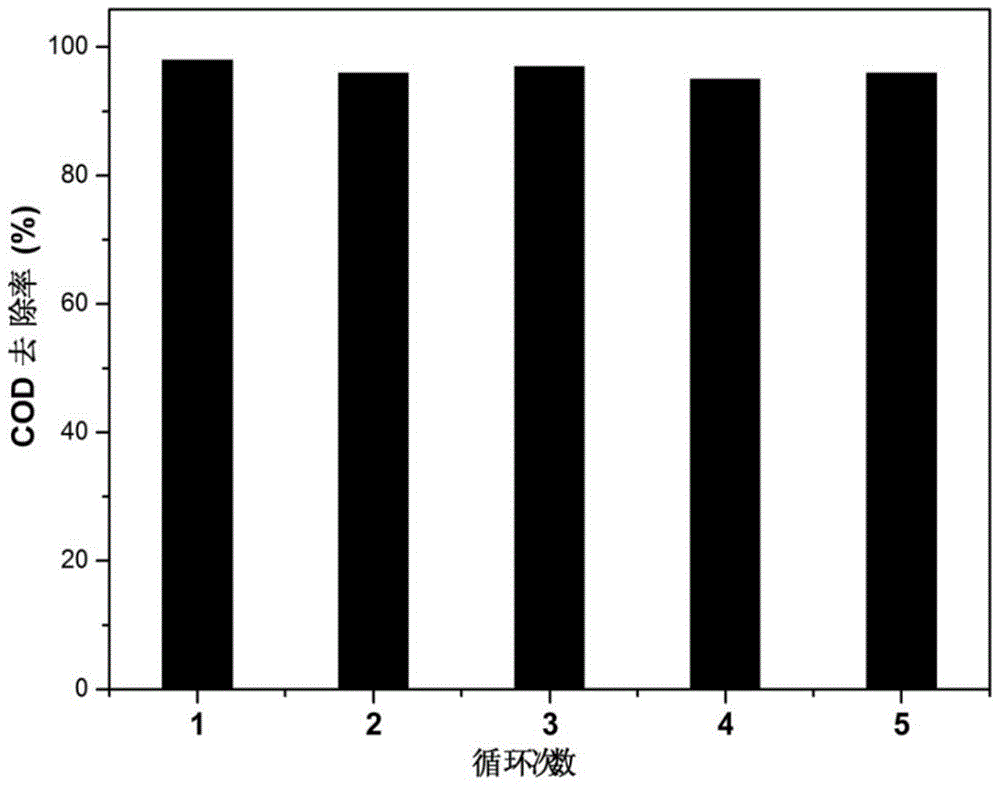

[0029] Take 0.1g of catalyst and 5mL of phenol solution into a 50mL intermittent stainless steel autoclave; 3MPa oxygen pressure, 190°C reaction for 100min, the reaction solution is centrifuged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com