Method for desalting of aqueous solution containing high-concentration sodium nitrate and/or potassium nitrate

A technology of sodium nitrate and potassium nitrate, which is applied in chemical instruments and methods, neutralized water/sewage treatment, water/sewage treatment, etc., can solve the problems of high energy consumption, achieve economical saving, environmental protection, simple operation, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

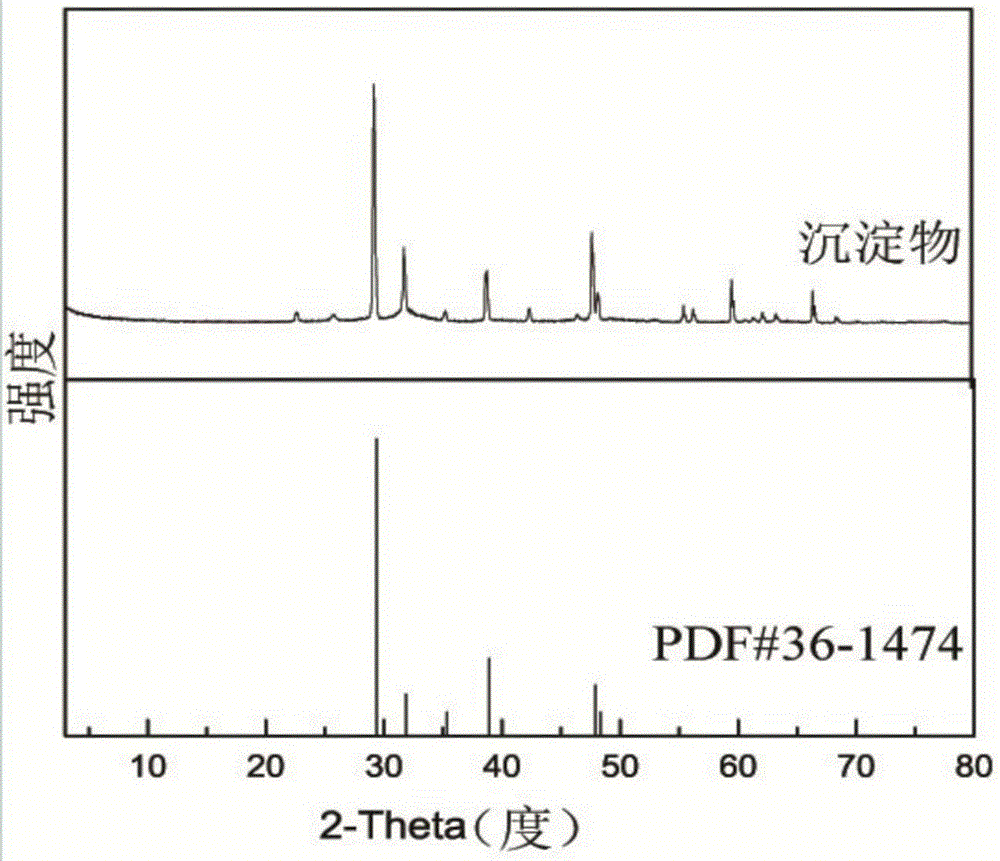

[0018] At 25–30°C, 16.7g NaNO 3 Dissolve in 100mL water (NaNO at 25°C 3 The saturation solubility is about 91gNaNO 3 / 100g water), under vigorous stirring, dropwise add 2.521g85%H 3 PO 4 , while adding 3.679g CaO to control the pH of the solution to 7–7.5. After the addition is complete, let stand, settle and filter to remove the precipitate containing sodium nitrate. In the XRD pattern of this precipitate (see attached figure 1 ), at 2θ=29.42°, 31.84°, 35.40°, 38.98°, etc., there are obvious characteristic diffraction peaks of sodium nitrate (refer to PDF#36-1474).

[0019] The weight of the precipitate is about 12.8g. According to nitrogen element analysis and inductively coupled plasma emission spectrometry (ICP), the N content of the precipitate is 8.28wt%, the Na content is 13.5%, and the removal rate is estimated to be about 38%.

Embodiment 2

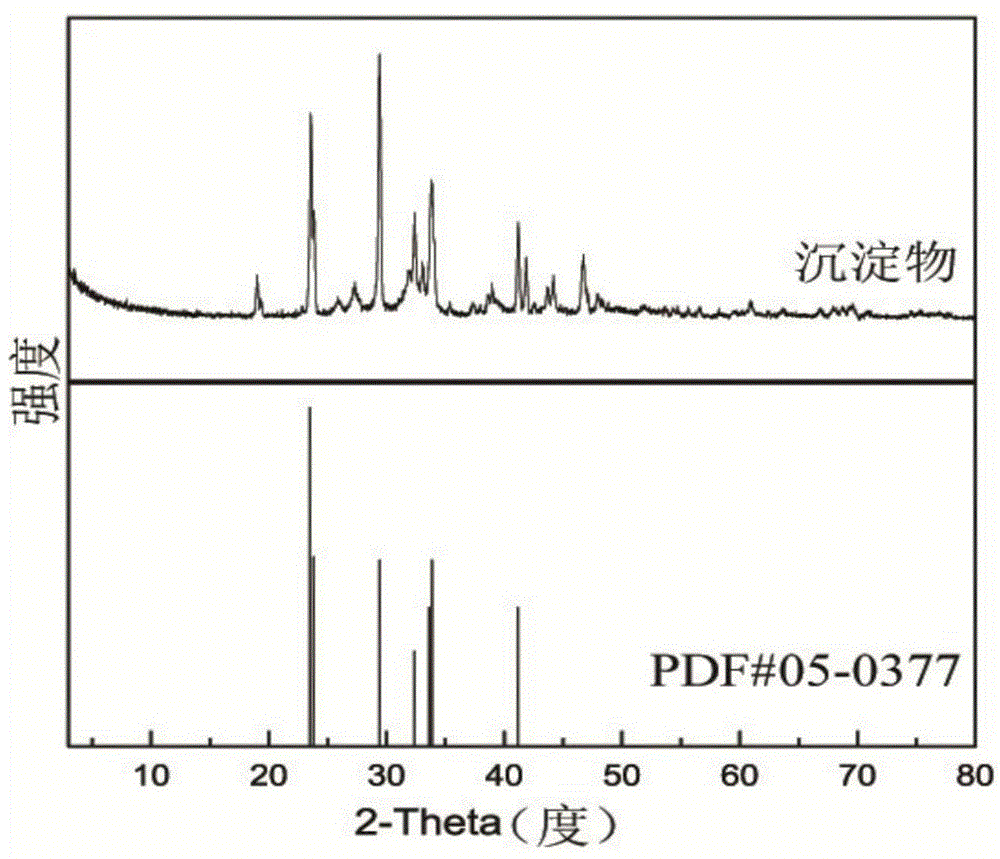

[0021] At 10–15°C, 19.0g KNO 3 Dissolve in 100mL water (KNO at 10°C 3 The saturated solubility is about 21gKNO 3 / 100g water), under strong stirring, add 6.8g Ca (H 2 PO 4 ) 2 ·H 2 O and 4.4g Ca(OH) 2 , to control the pH of the solution to 7.5–8.0. After the dropwise addition was complete, stirring was continued for 1 hour. After that, it was allowed to stand, settle and filter to remove the precipitate containing potassium nitrate. In the XRD pattern of this precipitate (see attached figure 2 ), at 2θ=23.42°, 29.24°, 32.22°, 33.70°, 41.02°, etc., there are obvious characteristic diffraction peaks of potassium nitrate (refer to PDF#05-0377).

[0022] The weight of the precipitate is about 18.1g. According to elemental analysis, the N content is 7.38wt%, and the K content is about 20.5wt%. It is estimated that KNO 3 The removal rate is about 50.5%.

Embodiment 3

[0024] At room temperature, 10gKNO 3 Dissolve in 100mL of water, add 30g of 85% H 3 PO 4 , while adding 12.0 g of CaO, stirring vigorously and controlling the pH of the solution to 8–8.5. After the addition was complete, stirring was continued for 0.5 hours. After that, it was allowed to stand, settle and filter to remove the precipitate containing potassium nitrate. The XRD patterns and attached figure 2 resemblance.

[0025] The weight of the precipitate is about 35.6g. According to the elemental analysis, the N content is 1.1wt%, and the K content is 2.8wt%. It is estimated that KNO 3 The removal rate is about 28.3%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com