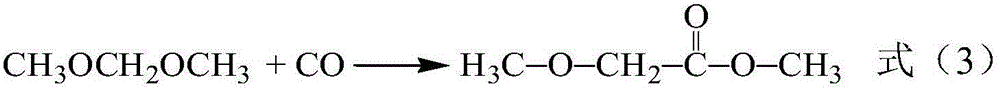

Methyl methoxyacetate production method

A technology of methyl methoxyacetate and carbon monoxide is applied in the synthesis field of methyl methoxyacetate to achieve the effects of easy preparation, mild reaction conditions and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation of embodiment 1 oxidation catalyst

[0045] Preparation of oxidation catalyst: Pour 4.76g of oxalic acid into 30ml of deionized water, stir to obtain an oxalic acid solution, add 2.22g of ammonium metavanadate to the oxalic acid solution, stir to obtain a dark green solution, add 10g of titanium dioxide powder, and stir evenly to obtain a paste After standing for 4 hours, it was dried in an oven at 100° C. for 12 hours, and then fired in a muffle furnace at 400° C. for 4 hours to obtain an oxidation catalyst precursor. Dissolve 0.25g of titanium sulfate in 6ml of deionized water, take 5g of oxidation catalyst precursor powder and immerse in the titanium sulfate solution, immerse at room temperature for 12h, dry at room temperature, dry at 100°C, and then bake in a muffle furnace at 400°C 4h. Press the calcined powder into tablets, crush it, and sieve the 40-60 mesh particles to obtain the oxidation catalyst, which is denoted as O1 # .

[0046] O2 # ~...

Embodiment 2

[0049] Embodiment 2 Oxidation catalyst composition analysis

[0050] Oxidation catalyst O1 was analyzed by X-ray fluorescence spectrometry #~O6 # The composition was analyzed, and the results are shown in Table 2.

[0051] Table 2

[0052]

Embodiment 3

[0053] Embodiment 3 solid acid catalyst

[0054] The relationship between the solid acid catalyst sample number and the catalyst type is shown in Table 3.

[0055] Among them, A1 # The perfluorosulfonic acid resin (NafionNR50) was purchased from Sigma-Aldrich, and was dried at 105°C for 12 hours in an air atmosphere before use, and 40-60 mesh particles were sieved.

[0056] A2 # ~A4 # Hydrogen-type molecular sieves were purchased from Nankai University Catalyst Factory. After roasting, tableting, crushing, and 40-60 mesh particles are sieved for later use.

[0057] A5 # 、A6 # Purchased from Sinopharm Chemical Reagent Co., Ltd., and dried in air at 100°C for 2 hours before use.

[0058] table 3

[0059] serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com