Penicillin G acylase mutant

A technology of acylase and penicillin, applied in the field of genetic engineering, can solve the problems of low ratio, reduction of antibiotics, low conversion rate of mother nucleus, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

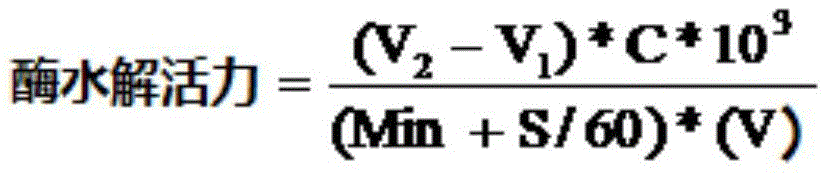

Method used

Image

Examples

Embodiment 1

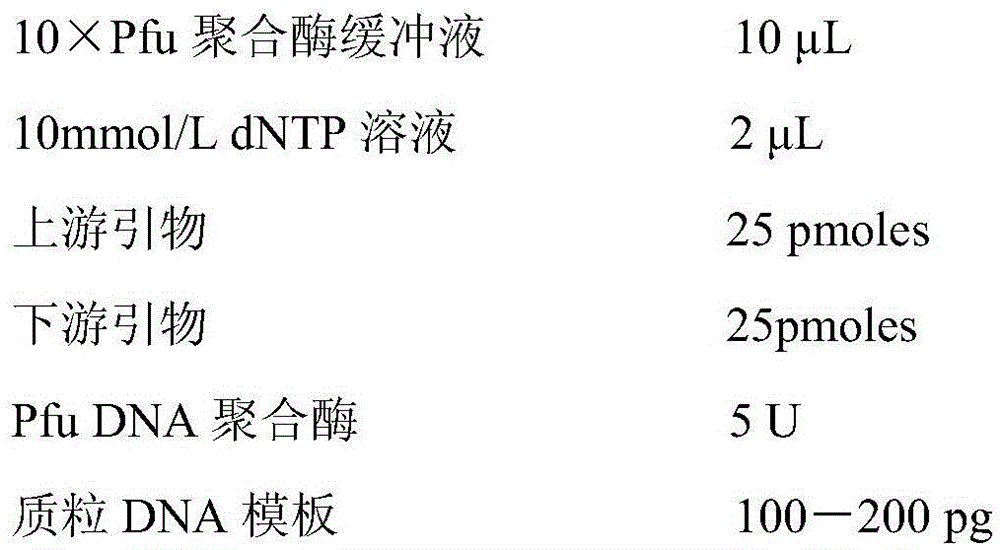

[0091] Construction of embodiment 1 mutant plasmid

[0092] 1.1. Primer design

[0093] According to the gene sequence SEQIDNO:2 of PGA derived from Achromobacter, and selected 7 mutation sites α4, α90, α146, α192, β24, β109, β488, the following 16 mutation primers were designed:

[0094] Table 1. Construction of mutant primers for different mutant AspPGA enzyme genes

[0095] mutation site

Mutation primer name

Primer sequence (5'-3')

Dα4

Dα4S F1

ACGGCCCCAAACCGCCTCGGGCAAGGTCACGAT

Dα4

Dα4S F2

ATCGTGACCTTGCCCGAGGCGGTTTGGGGCCGT

Dα4

Dα4L F1

ACGGCCCCAAACCGCCCTGGGCAAGGTCACGAT

Dα4

Dα4L F2

ATCGTGACCTTGCCCAGGGCGGTTTGGGGCCGT

Rα90

Rα90M F1

TGCCGGCCGCCGACATGCAGGTGCTGGA

Rα90

Rα90M F2

TCCAGCACCTGCATGTCGGCGGCCGGCA

Fα146

Fα146A F1

ACCATGGCCAACCGCGCTTCGGACGCCAACAGCGA

Fα146

Fα146A F2

TCGCTGTTGGCGTCCGAAGCGCGGTTGGCCATGGT

Aα192

Aα192E F1

CGCCGACCAC...

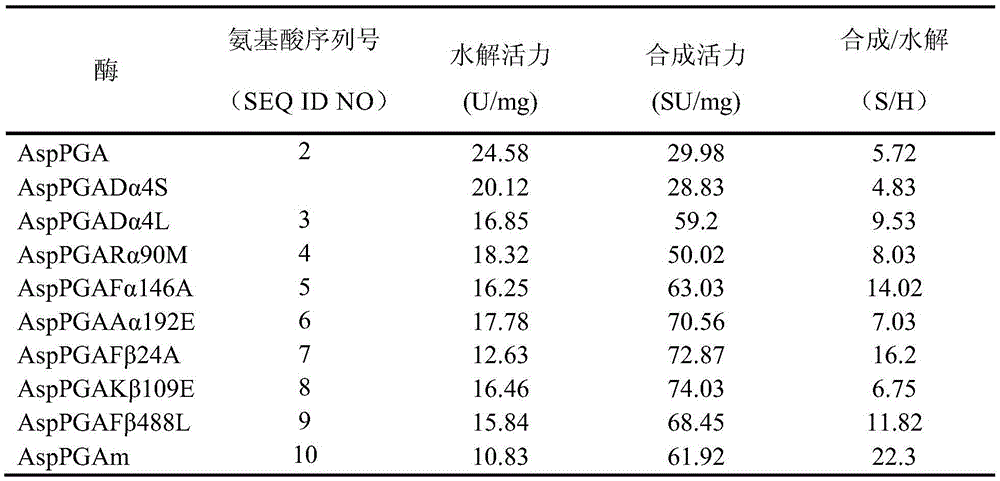

Embodiment 2

[0115] The acquisition of embodiment 2 engineering bacteria

[0116] With reference to "Molecular Cloning Experiment Guide" (third edition), edited by J. Sambrook, D.W. Russell (US), translated by Huang Peitang, etc., Science Press, Beijing, 2002, page 96 of the first chapter, respectively Nine kinds of plasmids (AspPGADα4S, AspPGADα4L, AspPGARα90M, AspPGAFα146A, AspPGAAα192E, AspPGAFβ24A, AspPGAKβ109E, AspPGAFβ488L and AspPGAm) were transformed into E. Spread on the LB selective plate added with kanamycin sulfate antibiotic, and incubate upside down at 37°C for about 12-18 hours. Those that can grow on the LB plate added with kanamycin sulfate antibiotic are transformants transformed with recombinant plasmids.

Embodiment 3

[0117] Embodiment 3 Engineering bacteria fermentation culture

[0118] Pick a single colony from the LB selective culture plate, inoculate it into 3 mL of LB liquid medium, add kanamycin to a final concentration of 100 μg / mL, and culture at 250 r / min at 37°C overnight; take 2 mL and culture overnight Inoculated into 200mL of LB liquid medium, cultured at 250r / min at 37°C for 4-6h, OD 600 When it reaches 1.0-1.6, the seed bacterial liquid is obtained. Insert the inoculation amount of 1:15 into a 5-liter fermenter containing 3 liters of TB medium, and ferment to OD at 37°C, 400rpm, and 1.3vvm fermentation conditions 600 When it reaches 1.0 (about 1 hour), adjust the temperature to 30°C, induce with a final concentration of 1% lactose, continue to cultivate for 2 hours, then add a final concentration of 0.5% lactose to induce, (the final concentration of lactose reaches 1.5%), Continue to cultivate for about 14-16 hours, and the fermentation ends. The fermentation broth was ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com