Supercritical extraction method for jute polysaccharide and application of jute polysaccharide

A jute and polysaccharide technology, which is applied in other chemical processes, water/sludge/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of low added value, difficult preservation and transportation of jute leaves and young shoots, and difficulty in promotion. , to achieve the effect of low cost, superior adsorption performance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 prepares jute polysaccharide

[0035] (1) two weeks before the florescence, harvest the leaves and tender shoots of "Zhongjute No. 4" (long-fruited jute cultivar); , dried in an oven at 40°C to constant weight;

[0036] (2) pulverize with ultrafine pulverizer, cross 100 mesh screen sieves, obtain the jute blade and the tender arbor tissue powder (abbreviated as jute powder in the following steps) that particle diameter is 0.15mm.

[0037] (3) add 10 times of weight deionized water in jute powder, stir, add 1% cellulase, 0.8% hemicellulase, 1.5% pectinase, 1.0% carboxypeptidase, enzymolysis process is in super Carry out in a critical carbon dioxide fluid, the specific method is: put the jute powder to be enzymolyzed into the high-pressure reactor, pump in carbon dioxide, start timing when the pressure is 10.0MPa and the temperature is 55°C, the enzymolysis reaction time is 3.5h, and the enzymolysis reaction time is 3.5 hours. After completion, the reaction...

Embodiment 2

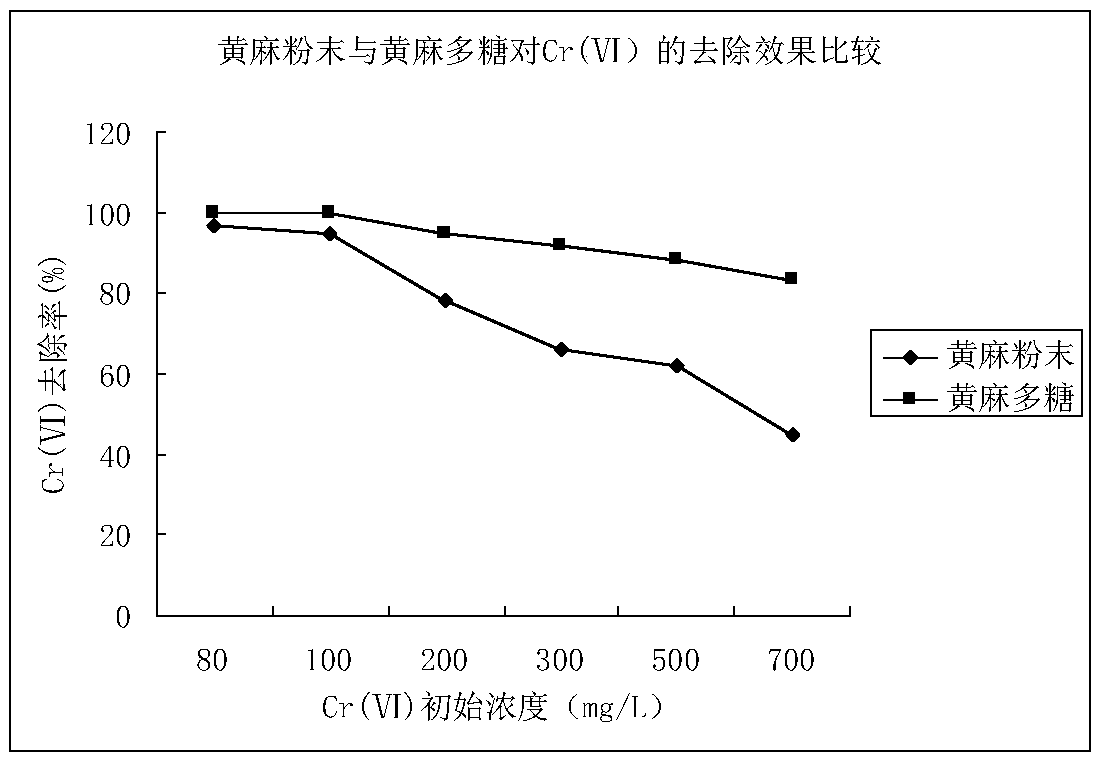

[0042] Embodiment 2 utilizes jute polysaccharide to remove Cr in the solution (Ⅵ)

[0043] (1) Get 100mL of potassium dichromate solution whose mass concentration of Cr(Ⅵ) is 200mg / L, and use HNO with a mass fraction of 60%-68% 3 and saturated NaOH to adjust the pH to 5;

[0044] (2) Add 1.5 g of jute polysaccharides to the sewage to be treated in (1), place on a stirrer and stir for 60 min at a speed of 150 r / min.

[0045] (3) Effect verification: 1.4 mL of the mixed solution was taken out, centrifuged (15000 r / min) for 2 min, and the supernatant was taken to measure the concentration of Cr(VI). The concentration of Cr(Ⅵ) in the solution was determined by diphenylcarbazide spectrophotometry (GB7467-1987), and the concentration of total chromium was determined by potassium permanganate oxidation-diphenylcarbazide spectrophotometry. Each test was repeated three times, and the average of the results was taken.

[0046] The test results showed that after the jute polysaccharid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com