Manufacturing process suitable for tungsten and steel connection of first wall part of fusion reactor

A manufacturing process and technology for wall components, applied in the field of metal diffusion welding, can solve the problems of poor connection performance and large differences in thermal expansion coefficients, and achieve the effects of high connection strength, good density and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Taking the hot isostatic welding of the first wall of the water-cooled ceramic cladding tungsten and low-activation steel of the China Fusion Engineering Experimental Reactor as an example for further explanation.

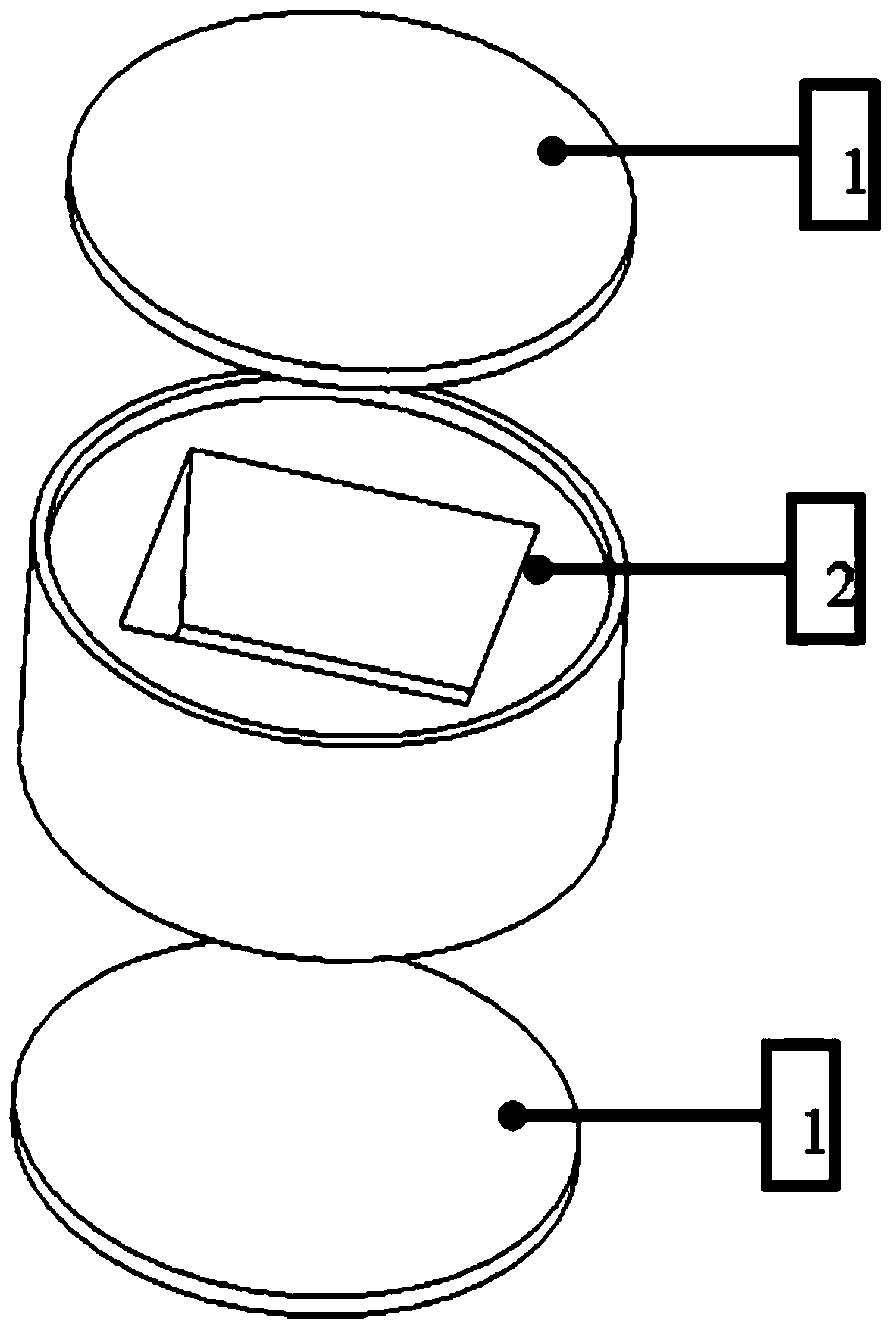

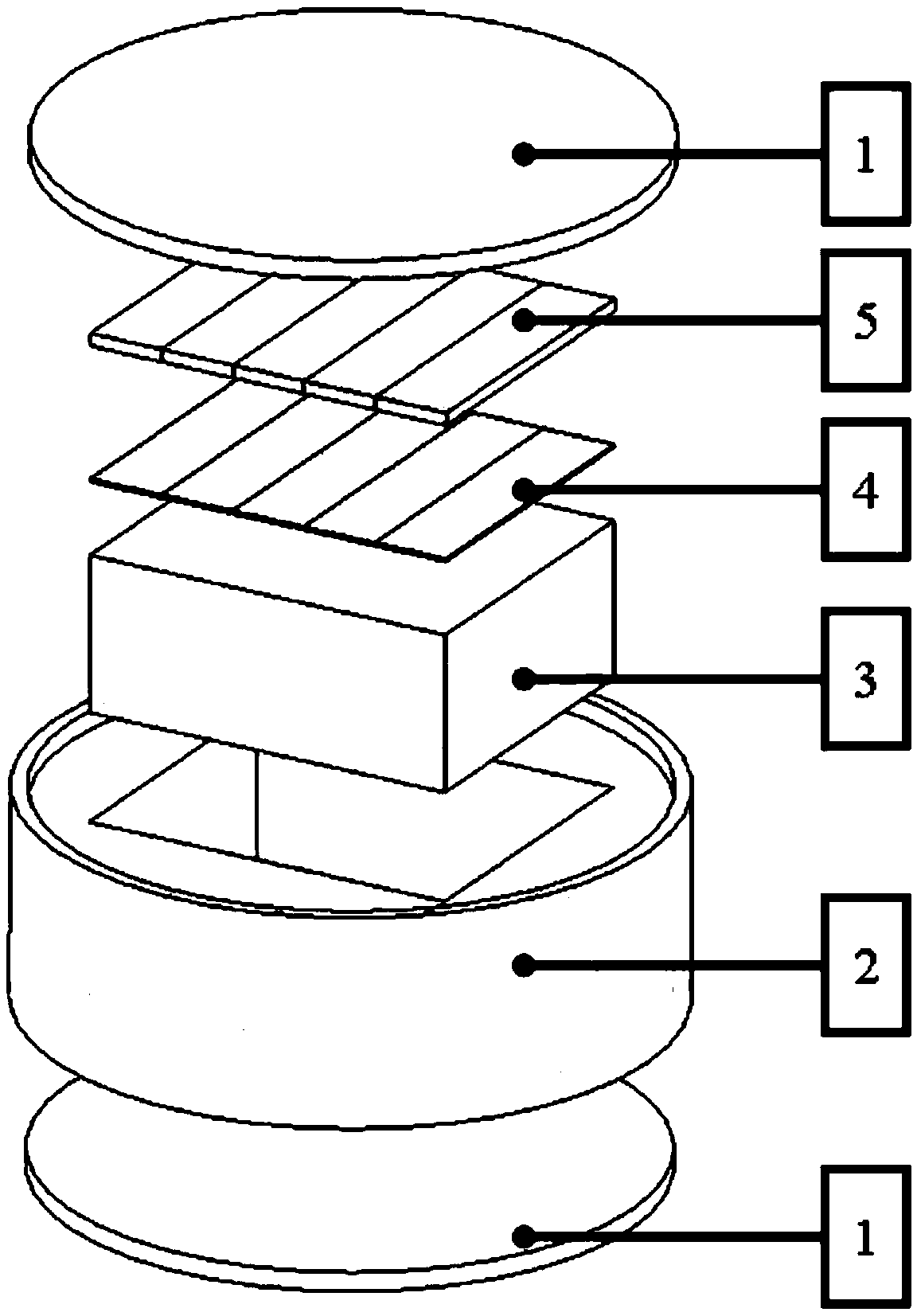

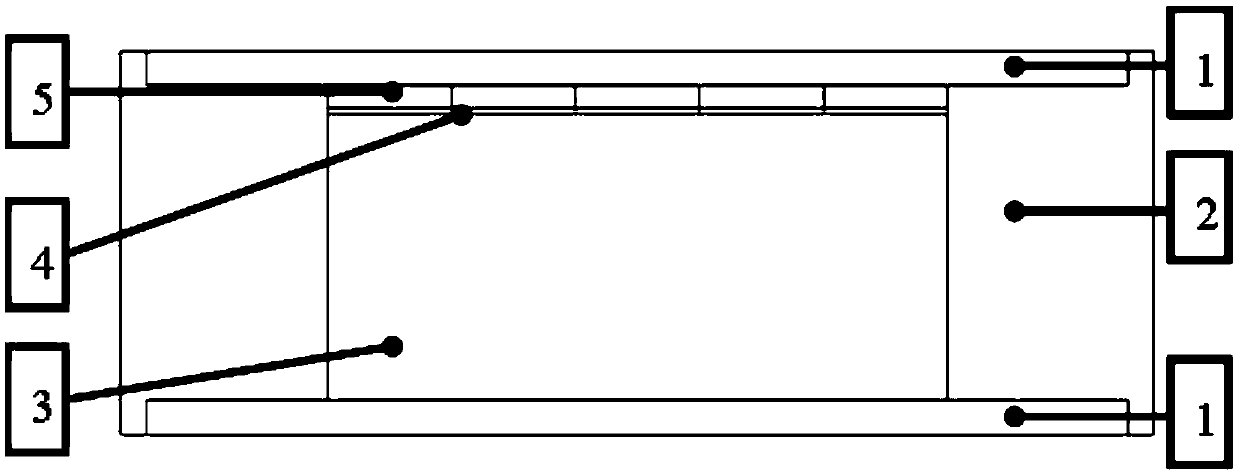

[0024] Such as Figure 1-4 As shown, a manufacturing process suitable for the connection between tungsten and steel of the first wall part of the fusion reactor, the process steps are:

[0025] 1) Machining: Process tungsten workpiece 5, intermediate layer workpiece 4, and steel workpiece 3 according to the design requirements, wherein the size of tungsten workpiece 5 is 12mm×50mm×2mm (in order to avoid cracking of large-sized tungsten materials during welding, multiple pieces are selected for this workpiece Small-sized tungsten array welding), the steel workpiece 3 is made of RAFM steel, the base size is 60mm×50mm×25mm, the middle layer workpiece 4 is made of titanium, and the size is 12mm×50mm×0.5mm.

[0026] 2) Finish the surface to be welded of the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com